Keep Tapered Bronze Seacocks Working Smoothly

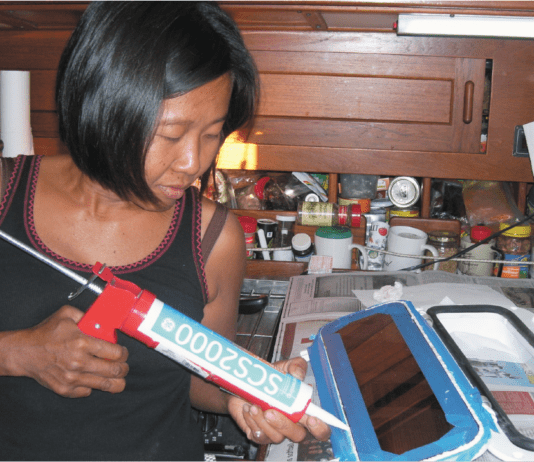

Are the tapered plug seacocks on your boat difficult or impossible to close? If you tighten the adjustment nut enough for them to stop weeping all over the inside of your boat, does it take two hands and a hammer to operate them? If so, it's time for an overhaul. Even if they worked well last season, a little care while the boat is hauled can save you a lot of grief in the future. As part of your boat's routine maintenance, tapered plug seacocks should be disassembled, cleaned, lubricated, and reassembled on a regular basis.

Freeing Seized Hardware

Simple ferrous-metal oxidation is a process in which iron, oxygen, and water chemically react, and it can cause rust to seemingly weld fasteners together. This unyielding grip often turns disassembly into much more of an ordeal, but with a few, regularly available products and a good set of wrenches, the big battle becomes a minor squabble.

How To Streamline Your Maintenance Program: A Beginner’s Guide

Owning and using a boat is all about maintenance. While maintenance is not fun—it can be filthy and arduous—it must be done if you...

3D Printing for Boat Projects: A Beginner’s Guide

In the old Star Trek TV series Captain Kirk would press a button on a machine called a replicator and request banana cream pie,...

DIY Tiller Lock and Emergency Tiller Pilot

Whether you own a Raymarine Tiller Pilot (ST1000 or ST2000) or the Simrad Tillerpilot (TP10, TP22 or TP32), the day may come when this...

Fair Through Hull Fittings: Essential to a Smooth Bottom

In light air, a major portion of the total resistance of a sailboat derives from skin friction. To oversimplify, the smoother the boat's "skin" — the submerged part of the vessel — the less power is required to drive it to a given speed. Put another way, given two boats identical in every way, including sail area, the boat with the smoother bottom will be slightly faster than a boat with a rough bottom in light air. Most racing sailors have learned the value of a smooth bottom. Ironically, cruising sailors can benefit at least as much from the creation of a low-resistance bottom as racing sailors, although you rarely see a cruising or daysailing boat with a bottom to match that of a good racing boat.

Descaling Solutions for Boats

In addition to all of that lovely salt, seawater is very hard, nearly saturated with calcium. All it needs is something to react with (uric acid in the head) or localized overheating (engine) to create concrete-like incrustations. Sometimes mechanical removal is possible; a favorite cruiser ritual involves hauling out the sanitation hoses and beating them on concrete to remove internal scale build-up. Heat exchangers can be reamed out with a rod, but most engine and plumbing systems are inaccessible without considerable disassembly.

The Get-Home Sailboat Tool Kit

The tools and materials required to maintain and repair everything on a boat will barely fit in a room. Just the kit required to maintain vital systems will raise the waterline of a large boat and is impractical in a smaller boat. Fortunately, when day sailing and even cruising locally, all we really need to do is get back to the dock...any dock.

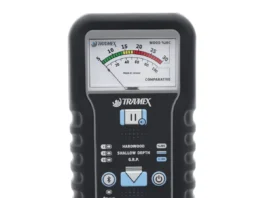

Five Best Specialty Tools

In fact our list is much, much longer than this, so we picked five specialty tools that we thought would help most sailors for...

Hose Fitting Tips

Pulling hoses is generally low on the fun list. They are in bad places, jammed onto crusty hose-fitting barbs, and have stiffened over the years. As part of our 2016 update on long-term tests, we needed to wiggle loose a few of the sanitation hoses were testing to see how they were looking on the inside-a job much less pleasant than new installation.