In Search of the Snag-free Clew

A smooth tack can be a thing of beauty, until a sheet hangs up and ruins it. A crew member must run forward to...

Rope Clutches Tighten Their Grip

Like the character Jaws in the old James Bond movie, rope clutches grab hold with a ferocious bite. This month we take another look at these toothy devices and how changes in materials and design are reshaping the art of clamping down. Since our last test (see Practical Sailor March 2009 online), several manufacturers have improved their existing designs to grip better than ever. Others have unveiled completely new approaches.

Dyneema Abrasion Test

As outlined in our previous report on lifelines, high modulus polyethylene (HMPE) fiber rope has revolutionized sailboat rigging during the past decade (see Fiber lifeline Protection Plan, PS September 2015 online), however sailors arent the only ones benefitting from the introduction of this super-strong, low-stretch cordage. Virtually any application that once employed a stranded wire-rope-ranging from tow cables to hoists-is now also served by HMPE. The widespread availability of generic brands of this super-strong, low-stretch cordage made us curious. How do these non-marine brand products compare to known marine brands? And what types are best suited for the various sailboat applications?

Wheel Thimbles for Synthetic Line Terminals

This is not a completely new concept. Spool thimbles have long been used on multi-pulley block beckets to increase the pin diameter to better...

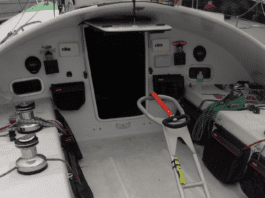

Refining Furling Line Fairleads

There was a time when headsail handling meant snapping on bronze piston-hanks and hauling on a smooth-running halyard. Times have changed, and now its all about how the furling drum rotates and the headsail wraps around a foil-covered headstay or freewheeling torque rope. (See PS August 2009 for our in-depth jib furler comparison.) Some systems behave more willingly than others, but all benefit from low-friction leads guiding the furling line back to the cockpit. The following report takes a close look at how these fairleads stack up and how much efficiency they add to the furling process.

Working with High-Tech Ropes

If you are working with low friction rings, sooner or later youre going to work with Amsteel and other high molecular polyethylene (HMPE) ropes, and that means learning to splice-in rings.

The Cruising Sailor’s Argument for High-tech Fibers

We’re not racers. A few ounces doesn’t matter to us, so why should we be interested in Dyneema, or any of the other popular...

PS Advisor: Rope Coatings to Prolong Cordage Life

New lines run fast. They fly through tackles and tangles fall right out. But they are also hard to hold in our hands, on...

Designing a Dump Line for the Multihull Mainsheet

Many of Practical Sailor's previous reports have explored the risks of multihull capsize, and what sailors and designers are doing to reduce this risk, which, though generally low, increases as designers push for more speed. One detail that we have not explored in great depth is the engineering of a “dump line,” which allows the helmsman (or automatic system) to quickly release the mainsheet in case a capsize is imminent. Simon Angus, a Canadian sailboat designer and builder who recently launched a new 40-foot catamaran that fits into a shipping container, has a manual system that involves the clever use of Ronstan’s constrictor textile rope clutches, which allows a person at the helm to quickly release the mainsheet with the swift tug on a parachute cord.

Years Later, Mast Mate Still Riding High

Mast steps are a great help when going aloft, but they add weight where it hurts most (aloft), and halyards love to get stuck behind them. One alternative is the Mast Mate webbing ladder, which hoists on your mainsail track.