Power Up: Installing Your Budget Lithium System—and Keeping It Safe

In Part 1 of this series, we discussed how to size your new lithium battery system, choose a battery, and assess the components and...

Morgan 41 Used Boat Review

The Morgan 41 sloop is arguably one of the best looking of many lovely dual-purpose sailboats that the Cruising Club of America handicap rating system engendered. One owner described his boat as a Bermuda 40 for a regular Joe, only prettier. Designer Charley Morgan traces the cruiser-racers heritage, particularly below the waterline, back to Olin Stephens famous Finisterre, and Comanche, a 40-foot centerboarder built by Wirth Munroe, son of famed sharpie designer and South Florida pioneer Commodore Ralph Munroe.

Power Up: Planning Your Lithium Conversion on a Budget

I once heard of a sailor who prided himself on sailing “pure”—no motor, no electrical, just wood and canvas. How he could dock and...

Quiet Power: Electric and Hybrid Propulsion at Annapolis

A tour of the 2025 Annapolis Sailboat Show showed signs of progress on the electrification of auxiliary power. Particularly notable was the emergence of...

Winter Sailing Tips for Diehards

For many seasonal sailors, the winterizing routine is already well underway. But there are more than a few diehard sailors in the mid-Atlantic regions, on the West Coast, and even in New England, who plan to spend all or part of the snowy season afloat. Some, we daresay, look forward to the quiet of winter. If youre toying with the idea of keeping your boat in the water during the winter, heres a short rundown on some of the more important steps to take.

Gas Vs. Electric Outboards: Consider Your Total Sailing Carbon Footprint

If you own or intend to buy an electric outboard because it is clean and quiet, read no further. Today’s four-stroke outboards are much...

Worship Your Universal M-Series Diesel With the Marinized Kubota Block

The Universal name resonates with many of us as one of the best sailboat engines available. Despite Universal Motor Corp. no longer being in...

Buyer’s Guide: 10 Gas Outboards For Cruising Sailboats

Plenty of day sailors and dingy owners are sold on the appeal of clean, quiet electric outboards, but do they make sense for cruising...

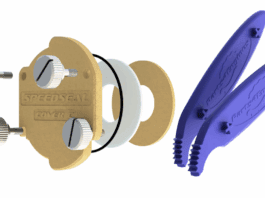

Prop and Shaft Check

A vessels drive train is typically defined as the components between the engine transmission coupling and the bitter end of the propeller shaft. For traditional drive trains, this includes the propeller, shaft, cutless bearing and packing gland, although the list could also be expanded to encompass ancillary items such as the rudder, engine mounts, and engine bedworks. Heres a look at two major drive train components you should know and what to look for when inspecting each. Next month well look at the components inside the boat-stuffing box, shaft, and coupler.

Determining a Fuel-efficient Engine RPM

My boat is a Hans Christian 41T, with a waterline length of 36 feet and a displacement of 38,000 pounds. The engine is a Volvo Penta TMD-30A rated at 90 horsepower. The prop is a Maxprop, three-blade, 20-inch prop with 12-inch pitch. A table illustrating speed at various RPMs shows that there is a linear increase of speed with RPM up to about 6 knots (2,600 RPM), but then the speed tapers off with increased RPM. Based on this, I presume that motoring at about 2,600 RPM is optimal fuel burn and speed. Is this correct?