Home Search

\"keel bolts\" - search results

If you're not happy with the results, please do another search

Mailport: Mainsail; Furl Fan; Keel Boats

TAMING THE MAIN

Your recently updated report on mainsail handling raised some questions (see “Taming the Main: Mainsail Handling for Bigger Boats,” tinyurl.com/bv5f4jfe). My 1985...

Sistering Keel Bolts

I have a keel bolt issue with my 1981 Freedom 33. To bolt the keel to the hull, Freedom set stainless J bolts into...

Bristol Channel Cutter 28: Circumnavigator’s Choice

INTRODUCTION

Like many sailors, Bill and Cathy Norrie had dreams of sailing the warm waters of the southern oceans, particularly when winter snows beat against...

Cabo Rico’s Classic Cutter

If we made a short list of traditional-looking cruising boats with trailboards and oodles of teak that dreamy-eyed readers most want to know about,...

Buying a Used Multihull

On monohulls, the greatest stresses and some of the most serious failure involve the keel, rudder, and chainplates. We inspect the keel bolts and...

Hunter 35.5 Legend Used Boat Review

Michael and Gail were not particularly looking to purchase a Hunter Legend 35.5 in early 2020. But they were searching through sailing magazines and...

Tartan 30: An Affordable Classic

If you're looking for a good buy in a weekender, it pays to buy the brand. There will always be compromises when it comes...

A Quest for Keel Integrity

Over the past few years, weve noticed a worldwide uptick in keel failures. The problem has yet to reach epidemic proportions, but we are...

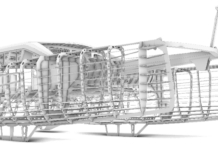

Keel Bolt Inspection and Repair

If your potential dream boat has more than 20 years behind her, one item that will likely come up on a survey is keel...

Keel Bolt Repair Options

In a few of our past reports on boat financing, Practical Sailor discussed how to pre-inspect your potential dreamboat before committing to the next...