Where Credit is Due: February 2011

Letters to Practical Sailor, February 2011. This month's letters cover subjects such as: Metz Antenna, Tipke Manufacturing, Facet/Purolator, Standard Horizon and more!

Mailport: February 2011

Letters to Practical Sailor, February 2011. This month's letters cover subjects such as: Micron in Fresh Water, Onboard Washing, Wiring Tools, Glazing and Bonding, and Paint-Away Spiders and more!

Extend LPU Life with a Few Basic Care Steps

The results derived from a professionally applied LPU topside refinish are as dramatic as the invoice that accompanies the makeover. The shiny, wet look and the protection it affords can last for years-whether its three years, five years, or nearly a decade depends upon how kindly the rejuvenated surface is treated. Two-part polyester urethane coatings such as Awlgrip II are tough, gloss-retaining coatings that will put up with some abrasion, but if you make it a regular occurrence, both the gloss and the paint will eventually go away.

Real-world Results

Our on-the-water testing backed up our panel test results, but also drove home some valuable surface preparation feedback. The key focuses of our testing on a dinghy, a Cape Dory Typhoon daysailer, an Ericson 41 cruiser, and a Catalina 22 were on nonskid painting and cabin and topside finishes

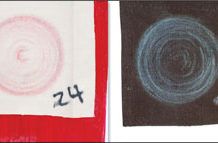

Topside Paint Test Panels Get Checkup

Practical Sailor tested four types of topside paint with different characteristics: traditional alkyd enamels, single-part urethane modified enamels, two-part linear polyurethane coatings and water-cleanup VOC-free finishes. The panel test comprised dozens of paints from Awlgrip, Crabcoat, Epifanes, Signature Finishes, Insignia Specialty Coatings, Interlux, Kirby’s, Pettit, Sherwin-Williams, and West Marine. Choosing the right topside paint has as much to do with matching paint characteristics with the applicator's needs and skill level as it does with the paint itself. While this test focuses on topside paints that are well-suited for DIY application, many are often used in pro applications as well.

Professional Advice for Do It Yourself Boat Blister Repairs

Earlier this year, reader and occasional contributor Fred Hatch found himself facing a quandary common among boat owners. The topsides of his 32-foot sloop were well faded, and small blisters were beginning to show along the waterline. Would he be in for an ambitious haulout and big yard fees, or might there be other remedies?

Sparkling Brightwork: Careful Attention to the Details

It takes practice to produce a perfect, mirror finish on varnished wood, but it is not so much a difficult task as an exacting one, where attention to detail and no short cuts are the secrets to success. Whether you are finishing new wood, refinishing old wood, or maintaining a finish in good condition, the basics are the same.

Upgrading the C&C 33 Part II

For hull bottom and topside repair, we love our Porter-Cable random orbit sander and WEST System Microlight Fairing Compound.

Keeping You Cool: Improving Your Icebox

Galleys on American production sailboats have come a long way in the last 20 years. We particularly remember one 40' cruiser-racer by one of the country’s most famous designers, whose galley consisted of a two burner countertop alcohol stove, a miniature sink, a few lockers, and an icebox: if you put 100 pounds of ice in it, it managed to keep small quantities of food at slightly below outside temperature for a few days at a time. Today, thank God, you’d probably find a better galley on any 30-footer.

Caring for Clear Plastics on Your Boat

There are three basic types of transparent plastics used on boats: clear vinyls, acrylics (the best known is Plexiglas), and polycarbonates (the marine standard is Lexan). Each has advantages and disadvantages, which is why most boats include some of each. Vinyl is actually plasticized, stabilized polyvinyl chloride (PVC). It’s the plastic of choice for any window or clear screen that rolls, folds, stretches or needs to be sewn to fabrics.