No one like dings, but we accept them as part of active sailing. Most boats have black marks behind winch handle pockets and dings on the mast. Chafe is an unending battle. Lines saw through gelcoat on cockpit coamings and under cleats when they bear and move under tension.

Friction makes adjustments more difficult. For mainsails using clew straps, outhaul adjustment is smoother if the underside of the boom is slippery. Thin carbon-fiber spars and hulls can’t take the chafe, nor the impacts that older, heavier aluminum spars and solid fiberglass hulls can. Can protective tapes protect sailboats and help them perform better? Our testers say, yes.

There are three characteristics that define each tape’s performance: chafe resistance, friction reduction (slipperiness), and impact protection. Chafe resistance requires that a tape be either very slippery, very hard and strong, or both. Stainless steel and Mylar tapes are strong and hard, and polyethylene tape is slippery and tough.

Friction reduction, or slipperiness, is defined by the coefficient of friction, a measure of how easily one material slides over another under load. Polyethylene tapes have been a staple of conveyor-belt systems for decades, where they keep goods sliding and reduce wear.

Impact protection requires a combination of strength and resiliency. Polyurethane films have been developed to protect helicopter rotors, airplane propellers, and wing leading edges from wear and dings. Tapes protect high wear areas where airplane flaps overlap and provide slippery surfaces on assembly line equipment. It’s very likely your new cars has a few tape strips covering paint around keys slots, in door jams, or where an accessory roof rack was added.

At the end of our testing, the best tape was 1,000 times better than the worst. A huge disparity, that we did not expect.

What We Tested

As we often do with fields that have such a vast range of products, we focused on a handful of products that represent a cross-section of the marketplace. There may be better tapes out there, and if readers have found one, please let us know.

Our list of test products included, polyurethane helicopter tape from ISC Racing Tape (8 mil), polyethylene Anti-Chafe Tape from Nautos/PSP, Mylar Sail repair tapes from Sailrite and Nautos/PSP, stainless steel WearAndTear Pads, Gorilla Tape, 3M Duct Tape and 3M Book Repair Tape.

How We Tested

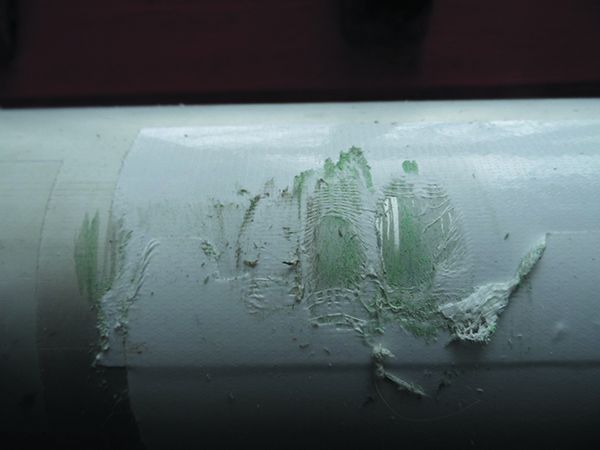

Chafe resistance was tested by applying a 2-inch wide strip to a 3-inch diameter aluminum mast section and hauling a ½-inch polyester rope across it through a 45 degree arc, tensioned with a 50-pound weight. This was repeated through 10, 20, 40, and 80 cycles. Impact resistance was measured by dropping a 5/16-inch stainless shackle repeatedly on samples affixed to sloping solid fiberglass and judging the damage resulting from the glancing blows. Some drops we targeted a round corner, and others we intentionally aimed the sharp pin head at the target. We measured the coefficient of friction by wrapping a 20-pound dumbbell handle in coarsely woven nylon webbing and determining the lowest angle at which it would slide. Finally, we installed the winning products on our test boat, each according to the job it seemed best suited to, and observed how they performed and held up over a season on the water.

Chafe resistance and impact resistance are really two very different things. We chose polyester over nylon for halyards because nylon stretches far too much and polyester is more chafe and UV resistant. On the other hand, anchor rodes and docklines are normally nylon, because nylon can provide much greater energy absorption. Likewise, stainless steel and Mylar (polyester) make sense for chafe protection, while a softer, more elastic polyurethane is more suited to impact protection. Where does polyethylene (milk bottle material) tape fall in this hierarchy, being both softer and far more slippery? We’ll see.

Chafe. Many of the tapes failed within a few cycles on our chafe rig, even the highly regarded ISC Race tape. On the other hand, 150 cycles did nothing more than make a polished spot one the stainless steel WearAndTear Pads and made no mark on the Mylar sail repair tapes or PSP Ant-chafe Tape. Carefully installed, they will last for years. Mylar is a strong, hard material which is very low-stretch, making it difficult to lay down smooth and wrinkle free if there are any irregularities. It is also higher in friction than polyethylene PSP Anti-Chafe Tape. In the end, the PSP Anti-Chafe tape took it, not because of low visible wear, but because of lower friction, ease application, and ding resistance. Note: we used the thinner 5 mil PSP tape on our test rigs. The 10 mil tape, installed on our test boat, performs even better, resisting heavy dings.

Anti-Chafe and Anti-Friction Tapes

| MATERIAL | STRENGTH | COEFFICIENT OF FRICTION (VS. NYLON WEBBING) |

|---|---|---|

| STAINLESS STEEL | 80,000 psi | 0.31 |

| POLYESTER (MYLAR) | 30-35,000 psi | 0.24 |

| UHMW POLYETHYLENE | 6,000 psi | 0.19 |

| POLYETHYLENE | 5-7,000 psi | 0.53 |

Friction. The coefficient of friction results (see value guide) tells the story. The PSP Anti-Chafe Tape is slick, the stainless Wear and Tear pads and Mylar tapes are similar to aluminum gelcoat, and the ISC helicopter tape is high friction. Interestingly, the reinforced Mylar was higher in friction because the fibers create ribs. We used reinforced Mylar under our mainsail clew strap for years, covering some rough spots on the boom where fittings have been removed. It wore just fine, but we switched to PSP Anti-Chafe Tape as soon as we saw the friction and chafe results. We have also installed the low friction PSP tape on the front side of the mast (faster tacks), on cockpit combings where lines were cutting into the gel coat and creating friction, and certain areas prone to dings.

Observations

Traction. Although we really like the PSP Anti-Chafe Tape on spars, it’s just too darn slippery for anything other than very small patches on deck. To a lesser extent, the same goes for stainless steel and Mylar.

We recommend either polyurethane tape (8 mil, ISC Surface Protection Tape) or non-skid tape (3M Safety Walk) for anti-ding patches around blocks and on-deck. That said, under an anchor chain we’d go with either a thick stainless plate (not WearAndTear Pads) or 10 mil PSP Anti-Chafe Tape, acceptable because we don’t walk in that area and the wear is hard. We have used vinyl non-slip tape under anchor chains and were not satisfied with the durability.

Anti-Chafe and Anti-Friction Tapes

| MANUFACTURER | MODEL | SIZE | THICKNESS | MATERIAL | DINGS | LINE STROKES | COEFFICIENT OF FRICTION | PRICE/AREA |

|---|---|---|---|---|---|---|---|---|

| NAUTOS / PSP | Antichafe Tape | 2" x 10' | 5 | Polyethylene | Fair | 150+ | 0.19 | $10/240 sq. in. |

| NAUTOS / PSP | Antichafe Patch | 5 pieces, 100 sq. inches | 5 and 10 | Polyethylene | Fair | 150+ | 0.19 | $10/100 sq. in. |

| NAUTOS / PSP | Sail window repair tape | 6" x 10' | 1.5 | Mylar | Very good | 150+ | 0.24 | $13/360 sq. in. |

| NAUTOS / PSP | Kevlar reinforced repair tape | 3" x 5' | 1.5 | Mylar with carbon fiber | Poor | 150+ | 0.37 | $19/180 sq. in. |

| SAILRITE | Laminate Repair Tape | 3" x 30' | 1.5 | Mylar & carbon fiber | Poor | 150+ | 0.37 | $29/ 1080 sq in. |

| PROTECT | Antichafe Tape | 2" x 5' | 5 | Polyethylene | Not tested | Not tested | Not tested | $17/ 240 sq in. |

| ISC | Race Tape | 2" x 12' | 12 | Polyurethane | Excellent | 1 to 5 | 0.53 | $25/288 sq. in. |

| GORILLA | Clear Tape | 1.8" x 75' | 3 | Polyethylene | Poor | 1 to 5 | 0.37 | $4/260 sq. in. |

| WEAR AND TEAR PADS | Wear and Tear Pad | 2 pieces, 2" x 6" | 2 | Stainless steel | Por | 150+ | 0.31 | $16/24 sq. in. |

| 3M | Duct Tape | 1.9" x 180' | 3 | Vinyl | Poor | 1 to 5 | 0.5 | $8/3888 sq. in. |

| 3M | Safety Walk | 1" x 15' | 19 | Vinyl | Good | 1 to 5 | 0.6 | $11/180 sq. in. |

ISC Surface Protection Tape is perfect for mounting hardware that is clamped to a railing. Placed under the clamps, the combination of toughness, invisibility, and high-friction keep clamps secure and protects the stainless railing. In fact, some clamp-on products come packaged with pads made from this type of tape. Small wonder it is often used on cars under roof rack mounts, where it provides invisible, tough protection.

Dings. The stainless steel WearAndTear Pads showed every impact, but they never cut through. Used in a location where shackles or blocks bang around, it’s going to show the mileage, but it will protect whatever is under it.

The ISC Surface Protection Tape, on the other hand, tends to be nearly invisible and self-healing from most dings, which explains its popularity with car enthusiasts. Unlike any other tape in this review, it readily conforms to mild compound curves.

The PSP Anti-Chafe Tape also showed every dent, but they were barely visible from a distance, and even the 5 mil grade did not fail. The 10-mil grade can handle most of what you can throw at it.

We installed both the ISC and PS tapes on the test boat mast, where they take impacts from the boom furling crank and low friction rings pressing tightly against the mast by the 8:1 Cunningham tackle. They both did very well, protecting the mast from dings. We installed PSP Anti-Chafe Tape, PSP Mylar Tape, and ISC Surface protection tape in certain ding-prone areas. They all performed well.

The ISC polyurethane tape may be useful for isolating stainless fittings from aluminum spars. It is thicker than ordinary tapes, tough, and unlike a thin sheet of plastic, will stay in place during installation. That is why some car dealers will use this tape to isolate roof racks and aftermarket products.

Carbon Fiber

Although gloriously stiff and strong for the weight, carbon fiber is brittle, and masts and booms can splinter under impact. ISC Surface Protection Tape will provide maximum impact attenuation. Other helicopter tape and leading edge tape products come in greater thicknesses, up to 30 mils.

Gluing on patches made from soft vinyl window material (like Strataglass) was suggested to us. Given the poor chafe resistance of ISC Surface Protection tape, we’re not recommending it for chafe or friction reduction. It could work for dings, we suppose, but polyurethane surface protection tapes seem like a much better choice.

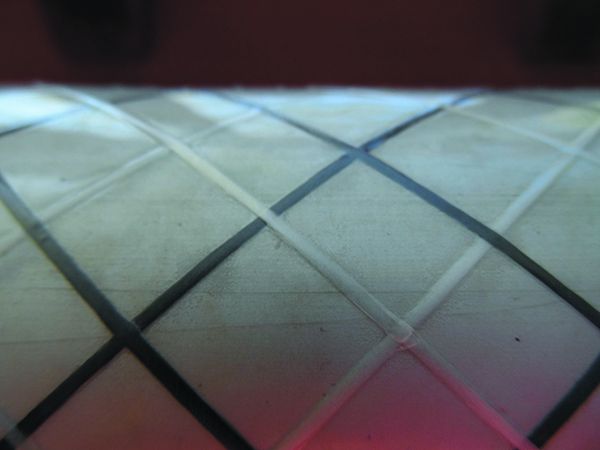

When applying WearAndTear Pads or 10 mil polyethylene tape remember that they do not conform to curves as easily. WearAndTear Pads suggest prebending the pad to match the curve. With 10 mil polyethylene tapes, avoid a bend radius of less than 1-inch. Pre-bending also helps, as does rounding the corners. However, Wear and Tear, PSP and ISC products all have excellent adhesives and we did not experience pealing problems.

WearAndTear Pads

Although only 2 mils thick, they survived the dings and showed zero wear in chafe testing. Long-term user reports were all positive. The downside is that they cannot tolerate compound curves, and they must be pre-bent to prevent peeling away from sharp bends. They are not recommended for aluminum spars because of corrosion concerns.

Bottom line: Best Choice for chafe resistance.

PSP Anti-chafe Tape

Available both as tape and patches, PSP anti-chafe tape is very slippery, very chafe resistant, and easy to apply. We recommend it for applications where ropes or webbing must slide smoothly. It is available in thicknesses of both 130 microns (5 mils) and 250 microns (10 mils). It worked well where control lines run across cockpit coamings and on the front of the mast, and it was a real winner on the underside of the boom, where it helped the clew strap outhaul more easily.

It was not as ding-resistant as the ISC Surface Protection Tape, but it can take a licking—particularly the 10 mil tape. We recommend the 10 mil tape for heavy duty applications. The 5 mil is more flexible, but unless the curve radius is less than about 1/2-inch, the 10 mil works just fine.

Bottom line: Our Best Choice for low friction, chafe, and ding protection. A Budget Buy too.

ISC Surface Protection Tape

Used to protect finishes on high speed cars and even aircraft, this is also called called racers tape, or helicopter tape. We tested the 8 mil thickness. There is also a 14 mil thickneess. The advantages of polyurethane are impact absorption and conformation to compound curves. The disadvantages are high friction and rapid chafe wear. We can see why auto racers and car aficionados like it for preventing dings from road debris, but it is not a chafe-protection product. On the other hand, the gloss is nice, it is self-healing for most dings, and the high friction is a real benefit when mounting clamp-on hardware to stainless railings. It also seems a natural for galvanic corrosion isolation when mounting hardware to aluminum spars.

Bottom line: Recommended for dings and mounting hardware.

Our tester got a serious workout running an old double braid sheet tied to a 50-pound log back and forth across the tapes (see Rhumb Lines “Thanks to the Crew,” Crude yes? A cardiologists nightmare? You betcha. But such are the lengths we’ll go to in order to get good data for Practical Sailor.

- Duct tape from 3M is a lousy chafe protector. It chafed through in 3 to 4 strokes.

- Reinforced mylar sail repair tape chafed through in 30 strokes.

- The Wear and Tear pad had deep dents after impact testing (less strenuous protocol that let gravity do most of the work), but none penetrated to the substrate below.

- After 150 strokes, the mylar window tape showed now visible signs of wear.

PSP Kevlar Sail Tape

The high strength and smoothness of Mylar seem to recommend it for many chafe and minor ding applications, but the ribs increase friction and it does not protect very well against dings.

Bottom line: Save this for sail repair.

Sailrite Laminate Repair Tape

This product is similar to PSP Kevlar Sail Tape. Some years ago we replaced the outhaul car on our F-24 test boat and replaced it with a polyester clew strap. We had moved the outhaul cleats forward because they were in the contact area of the clew strap, so we covered the fastener holes with a layer of gaffers tape, and then covered that with a layer of carbon reinforced Mylar sail repair tape. It wore well for 3 years, but friction made the outhaul difficult to adjust. When we replaced it with polyethylene tape, the outhaul worked much better.

Bottom line: Save it for sail repair.

PSP Sail window Repair Tape

The high strength of Mylar makes this nearly wear proof. In fact, this was the only sample where we absolutely could not distinguish between where the rope had run 150 times and where it had never been touched. Like the Kevlar tape, it offers little protection against dings.

Unlike the Kevlar tape, it is smooth and relatively low friction, though not in the same class as polyethylene tape. It is virtually invisible on a glossy surface.

Bottom line: Recommended for chafe. If it’s already in your bag, give it a try for chafe.

3M Book Tape

This tape is 3.5 mils thick and made of polypropylene. We tested this for vinyl window repair and found it to be very resistant to UV rays. Unfortunately, it is poor against chafe, friction, and impact.

Bottom line: Save it for clear vinyl window repair.

You don’t realize where chafe-protection tape is needed until you have a roll at hand. Here are some of the places we’ve found it useful on our test boats, or have seen it in use on other boats.

-

- The Corsair F-24 trimaran Brainwave has chafe tape on the floats to protect against chafe from spring lines. There are a few tiny wrinkles.

-

- Clear ISC Racer Tape protects a stanchion from scratches which will eventually invite corrosion.

-

- Nearly invisible anti-chafe tape at the front of the mast protects against dings and scratches and allows for faster tacks. Arrows indicate the tape edge.

-

- High tech carbon-fiber wear pads are nearly indestructible. We did not test these.

- The spot where the barber hauler has worn grooves in the gelcoat aboard tester Drew Frye’s trimaran now has chafe tape that has lasted over a year.

Gorilla Tape (Clear)

It performed reasonably well for window repair, but it was too stretchy and creeped under load. We thought it might have some good impact properties, but we were wrong.

Bottom line: We haven’t found a marine use for it.

3M Safety Walk

This is a good quality vinyl non-skid tape. We have used it for ding pads behind winch handle pockets and under the chain, leading to the windlass. Durability was acceptable, but it was hard to clean and it began to peel sooner than many of the other tapes we looked at in the test.

Bottom line: This tape makes sense if you also need some non-skid protection, but otherwise the protection tapes are a better choice.

3M Duct Tape

It failed every test, so there.

Bottom line: We’re keeping a roll on the boat anyway.

Conclusions

The product must fit the application. Stainless steel WearAndTear Pads are practically wear-proof on a cockpit coaming or under a mooring line, as long as there is no compound curvature. Helicopter and leading edge tape (ISC Race Surface Protection Tape) is good for ding protection, but fails miserably under chafing conditions. Mylar film is an interesting possibility, and we would consider it as part of a scheme to protect a carbon boom or mast, although not in areas where low friction was paramount. For our test boat, the big winner was PSP Anti-Chafe Tape. Our outhaul is now smoother, it protects the mast from handle and tackle dings, the barber hauler is no longer eating a grove through the cockpit coaming, and the sheets come through each tack that much faster.

SAILRITE, www.sailrite.com

RACERSTAPE, www.racerstape.com

NAUTOS USA, www.nautosusa.com

3M MARINE, www.3m.com

Darrell, I can’t seem to find “ICS” racers tape. I easily find “ISC” racers tape. Are they the same? Typo? Thanks as always for the great work and information. Steve.

I am disappointed you did not test ProTect tapes. It is among the most commonly used on race boats. Follow up?

Stephen, sorry about the confusion. Yes, there was a typo. The tape we tested was ISC tape (8mil), the text has been corrected. The 14 mil is thicker but has more trouble with compound curves.

Wish you had also tested some of the low friction and protective tapes that are designed for commercial use such as those from McMaster-Carr.

A good article however it made me think of my mizzen mast which is a free standing aluminum tube as on a Laser. The paint has worn at deck level so I am very interested in trying to improve on this. Would you have any comments on this type of application. The boat is a Nimble 24 yawl.

Many thanks. Ian Fisher

Another great article a suggestion for anti-chafe in compound curve areas would be the teflon paint used in aircraft where metal to metal chafe is inevitable that stuff is tough and almost impossible to remove without stripping, also on the 3m vinyl non-skid and in fact any vinyl tape or decal 3m edge sealer when carefully applied because it can be ugly, will keep them down much much longer. The edges of all vinyl decals on aircraft exterior are all treated with this

Very useful article!!!

The link to nautos USA is incorrect. The correct URL is http://www.nautos-usa.com

I used the Wear and Tear pads for several years to prevent lines cutting grooves into the cockpit coaming. I eventually gave up on the product because at least one edge would lift during the racing season.

Those edges are like razor blades. They sliced foul weather gear and several times I and crew ended up with cuts on our hands.

I switched to the PSP tape. It’s worked very well and is easier to install than the Wear and Tear product. And no more cuts!!!

Hey Darrell, I get a lot out of your test reports, thank you. But I’ve noticed that you consistently misspell “coaming”, as in a cockpit coaming. It’s not a combing!

Just now I see that my computer put red squiggles under “coaming”. So maybe it’s not your fault, but autocorrect from an ignorant computer.