EPA Mandate Sparks Fuel-vent Filter Test

Every day, as the temperature rises and falls, gases inside your fuel tank expand and contract. The emissions released during this diurnal breathing have raised concerns at the U.S. Environmental Protection Agency, and in July 2011, the agency mandated passive carbon canister filters on all installed gasoline-tank vent lines to collect fuel evaporation emissions. While older boats are not required to retrofit, we wondered how such a filter would affect fuel quality and engine performance-and whether carbon is the most effective filter media-so we launched tests using E10, gasoline, and diesel to find out.

Fuel-vent Filter Test Resources

Regulatory Information:EPA Marine Evaporative Emission Regulations (40 CFR Part 1060) EPA diurnal emissions testing protocol EPA baseline evaporative emission estimatesEPA memo...

Holding Tank Vent Fittings

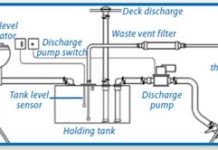

As I plumb the archives for holding tank replacement info, I find excellent related articles (PS, February 2012, March 2012, and April 2012); all remind me to build in good ventilation. However, I am unable to find guidance on the merits of ventilation fittings. These stand at the interface of tank gasses and other contents trying to get out, and the marine environment trying to get in. Issues such as shape, location, mounting, and materials concern me. Can you bring some fresh air to vent fitting merits?

EPA Needs to Revisit Fuel Vents

Well, the first year without subsidizing U.S. refiners and farmers for using corn to make ethanol-blended gasoline has passed, and the world didnt end. Gas prices havent soared, growing corn is still profitable, and most of the members of Congress who reversed their political stands are still in office. Im pretty certain that when historians and economists look back on the 30-year-old, $20-billion tax break for turning corn into fuel, it will be seen for what it is: failed politics masquerading as clean energy policy.

Biobor EB Still Tops in Additive Rematch

In the August 2012 issue, Practical Sailor reported on the effectiveness of eight common fuel additives in reducing salt-induced galvanic corrosion in E-10 fuel systems. Some makers suggested our test was too tough and too short, so we have repeated the test, for five products, reducing the amount of seawater from 0.03 percent to 0.015 percent (equivalent to four drops of water in a 1-quart tank) and increasing the exposure time to two months. Included…

A Boat Buyer’s Recourse

The AC pump passed inspection, but it never turned on again. Then there was the leaking diesel fuel. The previous owner had added see-through, 30-micron filters where the fuel exited the tank because the metal ones at the engine are hard to reach and inspect. I have since learned that this type of filter is sure to leak, as diesel will soften the plastic housing. I am told that the Coast Guard will hammer you if they find them installed.

A Boat Buyers Recourse

The AC pump passed inspection, but it never turned on again. Then there was the leaking diesel fuel. The previous owner had added see-through, 30-micron filters where the fuel exited the tank because the metal ones at the engine are hard to reach and inspect. I have since learned that this type of filter is sure to leak, as diesel will soften the plastic housing. I am told that the Coast Guard will hammer you if they find them installed.

E-10 Fuel Additives that Fight Corrosion

Practical Sailor’s original goal with this evaluation was to run a long-term test of fuel additives. Instead of adding heat or oxygen or excessive corrosive materials, we would substitute time. After six months of testing additives in E-10 gasoline, we found no measurable corrosion, so we elected to add a small amount of seawater and compare fuel samples after one month. The results were surprising to even our testers. The additives we tested were: Hammonds’ Biobor Ethanol Buster, CRC’s Phase Guard 4, Mercury Marine’s Quickstor, PRI-G, Sea Foam Engine Treatment, Sta-bil Ethanol, Star Tron Ethanol, and ValvTect Ethanol.

Testers Tinker with Tinker Bell-sized Fuel Tank

If you really must know how we compared the fuel additives, here are the particulars.

PS’s Best Practices to Combat Fuel Problems

Additives can’t solve real gasoline-quality problems. At best, consider additives to be only a final tweaking opportunity, something to supplement the following fuel management practices.