Although you can allow your varnish and hull paint to fade, crack, or peel with no more penalty than the disdain of those who mistake shine for soul, you don’t want to let your non-skid deck paint lose its grip. Even the most soulful boat evokes a sense of pity if its owner is lying flat on their back asking for help.

Refinishing your boat decks nonskid coating is a big project, but so are the payoffs. Not only does it escape the stink-eye from any judgie neighbors, it is a whole lot safer. Here some tips to help you get more mileage out of a nonskid restoration.

Proper Application

The secret to durable non-skid starts with proper application.

Surface prep: We all know proper surface prep can make or break coatings applications, but it also directly affects the coatings service life. Always follow makers recommendations.

To prime or not to prime? That depends on the deck substrate being painted and the type of paint being used. If the surface is bare wood or bare metal, plan to apply a coat of primer (and a sealer for wood). A one-part primer is often sufficient, but a two-part epoxy primer will offer more durability and hardness. Bare fiberglass requires a dewaxer, scuff sanding, and a coat of primer when applying most paints; however, some paints like Durabak and KiwiGrip recommend primers only for bare metal and wood.

Application: The surface must be clean and totally dry. After sanding, wipe it down with xylene, dewaxer, or acetone. Some paint makers warn against using solvents, so be sure whatever you wipe down with is compatible with the paint.

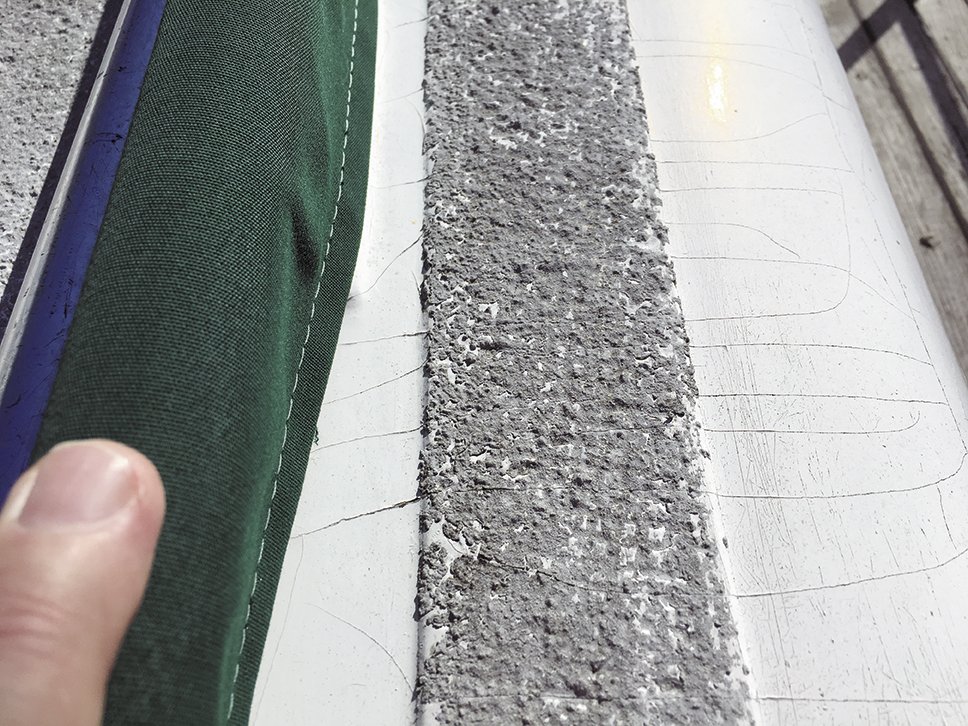

When it comes to using a paint and a nonskid additive, we recommend combining the mix-in and broadcast methods to get the most uniform grit pattern. Mix the nonskid additive with the paint, roll it on with a high-nap roller, and sift more aggregate on the paint while its tacky; once the paint dries, you can brush off the excess and apply a second coat in the same manner. You can make an aggregate shaker by poking a dozen or so holes in the lid of the can with an ice pick, then up-ending it to sprinkle the additive across the deck. Pre-mixed nonskid paint users can also broadcast nonskid additive atop coats of the pre-mixed paint for a more aggressive grip. For increased durability, we suggest mixing nonskid additives with two-part linear polyurethane paints (LPU).

Be sure to keep the coats thin-multiple thin coats are preferred over one heavy coat-and plan to apply the paint when there is minimal humidity. If you’re headed for the tropics, choose white or a very light shade. That teal non-skid that looks so great in air conditioned boat show hall will be a serious foot-scorcher in hot weather.

Curing: Follow the makers recommendation for dry time, and be sure to allow the paint to fully cure before subjecting it to foot traffic. This allows the paint to achieve maximum hardness, making it more abrasion resistant and longer lasting.

Mat Installation: If you’re installing a self-adhesive mat, application is a no-brainer. Just be sure its where you want it before you stick it to the deck; contact adhesives don’t allow the small wiggle adjustments that epoxies do in application.

Testers also learned a few application lessons the hard way when installing nonskid mats with two-part epoxy. The epoxy usually has about an hour of pot life before it becomes permanently stuck to whatever its touching, so clean up any errant epoxy with a solvent as soon as possible.

It’s also best to decide on the mats exact location before mixing the epoxy; you can use paper templates to help in this process. Be sure to leave a lip around the mat edge that is free of glue; the epoxy will squeeze into the bare area when the mat is put in place.

Regular Maintenance

Boat bath: Nonskid paints and mats should be cleaned regularly to remove abrasive salt spray and dirt. Wash with standard, mild boat soaps (PS, January 2013) or household cleaners and a soft- to medium-bristled brush. Steer clear of bleach and other chlorinated or acid-based cleaners as they can affect the paints color pigments and UV inhibitors. Be sure to rinse the decks well with fresh water, when possible.

Mold and Mildew: To prevent mold and mildew, you can lightly scrub the surface with an ammonia/detergent solution. To spot clean areas that are heavily soiled or show mildew, youll likely need to step up to more aggressive cleaner. Pettit recommends its Bio-Blue 92; the blend of cleaning agents and silica grit also can be used to de-wax or etch during surface prep. Durabak recommends fighting mildew and stains with a disinfectant like Lysol, and KiwiGrip advises using bleach or a mild acid solution to remove mold and mildew stains.

Wax Not: While waxing can breathe new life into topside paint, the paint makers we talked to do not recommend waxing painted nonskid. Most nonskid paints and bead/powder additives have UV protection built in, and the paint formulas include UV absorbers, making waxing unnecessary.

Touch-ups: Address any peeling or worn nonskid paint as soon as possible. Most of the nonskid paints we tested are easily repairable: A bit of scuff sanding, cleaning, and touch-up painting will keep the coating from meeting an early demise.

Longevity expectations

Nonskids life expectancy can vary based on type (paint vs. mats, and paint type), boat location (UV-saturated South Florida vs. overcast Seattle), and how it is cared for. In our non-skid surface tests, the soft-foam mats we tested did not weather as well as more rugged mats like Treadmaster-nor did some one-part paints, but they can be freshened up with a little sanding and a recoat. For example, Pettit reports that EZ-Decks should perform well in Florida for about three years before needing a recoat.

A properly applied two-part LPU should deliver at least five years before needing recoating—you could get as long as ten. Less viscous polyurethanes like Durabak and KiwiGrip claim to last a decade, but in our experience with Durabak five years is the maximum in the marine environment. See the November 2021 issue of Practical Sailor for our most recent non-skid paint test report.

My challenge is what to do with the existing non skid. If it’s got hard material, and thin glass underneath before ply, then sanding is a real concern. Almost need to go over existing awlgrip.

Exactly what I was thinking..

How about restoring the molded in non-skid. These oxidize and are hard to bring back. I’ve tried some processes found on youtube without success. Could be operator error. A product I think called Aurora has very mixed reviews. Devoting some research on this problem would be great.

I had a friend who overcoated gelcoat nonskid with more matching gelcoat and a stippling roller. He had a Taiwan trawler and he wanted a more aggressive grip. It worked almost too well and had a great grip!