Engine Coolant Replacement

In your recent article on engine coolants (see PS October 2014 online), you wrote about replacement intervals for coolants, and Im looking for clarification. You indicated that the following heavy-duty coolants for diesels were coolants, not antifreeze: Zerex GO5, Peak Final Charge NOAT, and Detroit Diesel Power Cool Plus. You also suggested that I replace the coolant every 1,000 hours, . . . (and for little used engines) changing the coolant every five years is a more practical approach.

Will Your Tanks Be Clean Next Spring?

When contributor Drew Frye commissioned his familys PDQ 32 catamaran six years ago, his daughter asked, What are these pink lumps in the sink, Dad? The toilet bowl was even more spectacular, a science project in a dozen hues of pink, green, yellow, and black. The boat had been winterized for some time, down in south Chesapeake Bay, where winters are mild and many boaters and don't take freezing seriously.

Testers Check Growth in the Lab and on the Boat

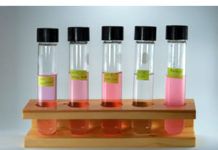

When testing a chemicals toxicity and its ability to biodegrade, a common procedure is to dilute each target chemical at various ratios of interest, and then to inoculate each with an acclimated microbiological seed. For our test, the seed was developed by filling a five-gallon bucket with several gallons of water and a weak mixture (two percent total glycol content) of all of the winterizing agents to be tested.

Coolants that Fight Corrosion

Salt and water conspire to reduce our boats, our pride and joys, to pitted and unreliable money pits. Weve investigated corrosion of wiring (see PS July 2010 online), gasoline (see PS August 2012 online), diesel (see PS August 2013 online), and winterizing fluids (see PS September 2014 online), uncovering additives and practices that dramatically reduce deterioration and increase reliability. Engine cooling systems have similar vulnerabilities, and fortunately for us, the automotive engine manufacturers have invested millions in finding those solutions. However, the marketing materials don't always make the differences clear, and its hard to know which product is the best for your engine.

ASTM D1384 Serves as Model for Testers

Samples were tested for corrosion protection following the ASTM D1384 Corrosion in Glassware method (www.astm.org). Samples were diluted to 33-percent glycol, dosed with ASTM synthetic corrosive water (similar to 2-percent seawater), continuously aerated, and heated to 190 degrees for two weeks. As a laboratory control, a reference coolant (ASTM D 3585) was also exposed to provide a baseline.

PSs Top Picks for Winterizing

Protecting marine water systems from freeze damage is a deceptively simple goal. The terminology and various product claims can be confusing, and what seems like a good common-sense decision can lead to trouble. We tend to think that all water systems are the same; that boats as well as RVs can be protected by the same pink antifreeze without any further thought. However, many of the problems we associate with age, or normal wear and tear-stiff impellers, cracked pipes, ruined joker valves, and foul-tasting tap water-can often be attributed to errors during winterization.

Test Checks Burst Point and Freeze Protection

We tested each product for glycol content using a refractometer and either the ethylene glycol or propylene glycol scale, as appropriate. In the case of Camcos Arctic Ban and Sudburys Winter Stor, some portion of the freeze protection is provided by ethanol, and such mixtures cannot be easily evaluated by any field method (test tape, gravity, refractometer) unless the exact proportion is known, which we find troublesome.

Step-by-step Winterizing Tips

Winterizing agents should never be used in freshwater tanks or hot-water tanks. Doing so will greatly increase the chances of biological growth, which can result in foul-smelling, bad-tasting water. If your boats water system does not have bypass fittings that allow you to add glycol to waterlines, install them. The addition of a few simple fittings can reduce the annual process from hours to minutes for the cost of a few jugs of glycol.

Refractometer Takes Out All the Guesswork

What matters most, our testing confirms, is not so much which brand of pink stuff you choose, but how you use it. Even the best product, mixed with too much water left in the line, results in a blend with unknown and perhaps unsatisfactory performance. While this may not be critical in North Carolina, sailors in Wisconsin need to get it right.

AWAB, ABA Top Long-term Test

General-purpose, relatively inexpensive hose clamps are all over most boats, but there are some applications where using a higher quality, corrosion resistant clamp is critical-such as engine hoses and through-hulls. Most quality clamps are stamped stainless steel, but there are many grades of steel, and making an alloy stainless and corrosion resistant is complicated and costly. You start with iron, which rusts easily, and through multiple processes, you add proportions of elements such as nickel, manganese, molybdenum, and chromium. Different percentages of these elements will improve the desired strength, hardness, and flexibility, as well as corrosion resistance, of the steel.