Photo by Frank Lanier

Boat decks take a beating. Besides daily flogging by the sun and other merciless weather elements, they face constant foot traffic and regular scrubbing, often with harsh cleaners. Eventually-and understandably-this abuse takes its toll on factory-molded nonskid, and once nonskid loses its grip, resurrecting it moves from an aesthetic fix to a safety issue, making it a must-do on the maintenance to-do list.

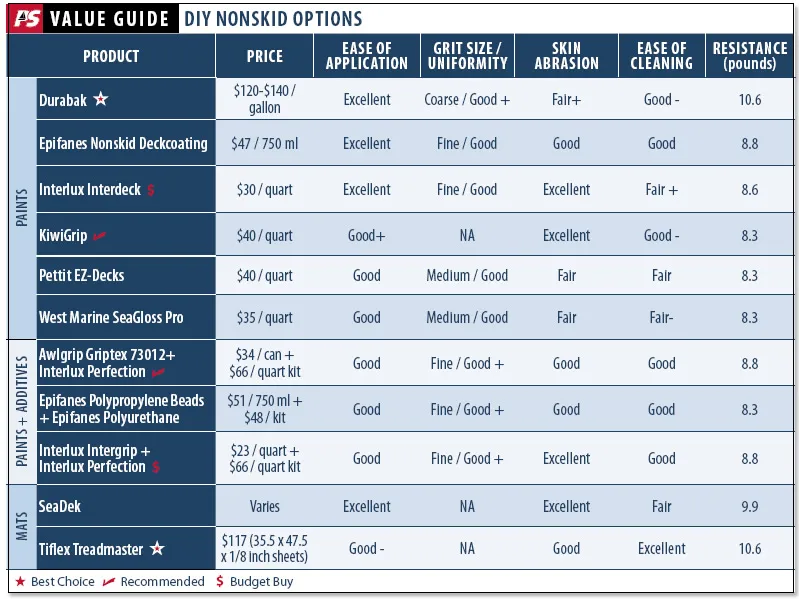

Boat owners looking to put some stick back into a slip-and-slide deck have a few options: apply a deck paint with a nonskid additive or glue sections of specialized nonskid mat to the deck. There are several variations of the paint method. Some deck paints come pre-mixed with a nonskid compound (polypropylene, silicon oxide, pumice, or polymers) in powder or bead form, or you can buy the additive separately and mix it with a paint before applying, or broadcast it on top of the wet paint with a sifter-shaker.

Weve had mixed results with DIY mixing and sifting, but weve gotten the most uniform grit pattern by combining the two methods: Mix the nonskid additive with the paint, roll it on with a high-nap roller, and sift more aggregate on the paint while its tacky; once the paint dries, you can brush off the excess media and apply a second coat in the same manner. You can make an aggregate shaker by poking a dozen or so holes in the lid of the can with an ice pick, then up-ending it to sprinkle the additive across the deck.

In the Feb. 1, 2003 issue, we tested a variety of nonskid options, including multiple pre-mixed paints, nonskid paint additives, and large rubber mats. With this report, we take a fresh look at the topic and the products available for a do-it-yourself nonskid overhaul.

What We Tested

We limited the test field to commercially available nonskid options that the average boat owner can easily apply. We did not include sand or crushed walnut shells for a few reasons: fewer boat owners are using them as additives these days, commercially sold products yield better results, and sand or walnut shell tend to be very rough on human flesh.

The test lineup comprised one paint with no filler media, five paints ready-mixed with nonskid compounds, three nonskid additives that testers mixed with two-part topside paints, and two nonskid mats (one is self-adhesive, and one is glued on with an epoxy). All of the products can be applied to fiberglass, wood, or metal, and all are readily available from online stores and marine chandleries. We tested a range of grit sizes-from fine to coarse-but many of the test products are also available in various grits.

Manufacturers represented in the test included the typical big players in the marine coatings world-Pettit (Kop-Coat), Epifanes, AkzoNobel (Interlux and Awlgrip), and West Marine-as well as two U.S. companies specializing in nonskid products-Pachena (KiwiGrip) and Durabak-and two others that manufacture nonskid mats for the recreational boating market-Tiflex (Treadmaster) and SeaDek. A third mat-maker, Soft Deck (www.soft-deck.com), sent two mats for evaluation after this test was complete; well be putting the Soft Deck through its paces for a follow-up report.

For details on the application, test protocol, and rating system, check out How We Tested. (On right)

What We Found

None of the test products was particularly difficult to apply, but the pre-mixed paints and self-adhesive SeaDek mat were the absolute easiest, followed by the epoxied Treadmaster mat and the nonskid additives, which were mixed with two-part polyurethanes, a process that pretty much doubles the application steps.

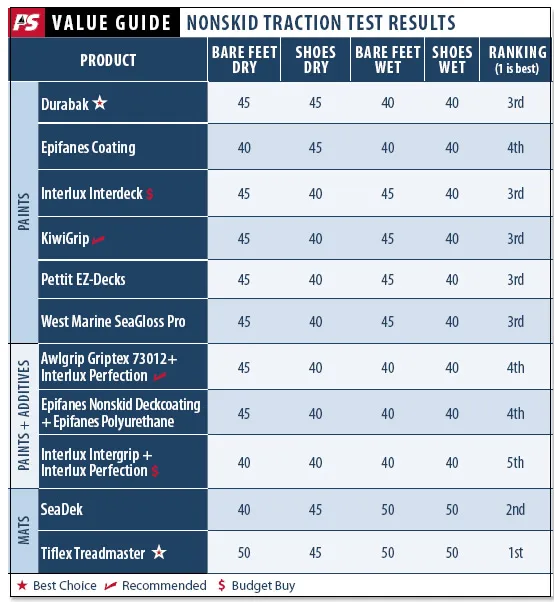

Both the Treadmaster and SeaDek mats offered better traction than any test paint or additive; they were the only test panels that allowed testers to stay put at a 50-degree incline in the grip test.

Overall, the pre-mixed paints fared better in our traction test than the additives with Durabak leading the pack. However, the benefit of using a separate additive or a product like KiwiGrip is that users can amp up the grit as they see fit. The products allow more control over the density and spacing of the aggregate granules and the texture, so users can customize the coverage-for example, applying more where the most traction is needed like a cockpit sole or around the mast and less grit in areas where skin-on-deck contact most often occurs, like swim platforms or along the rail on race boats. Its a good idea for first-timers to do a few practice runs with these products to figure out how best to achieve the desired finish. This is particularly important with paints like KiwiGrip and Interdeck that call for stippling or textured finish.

The top three finishers in the traction test were the Tiflex Treadmaster, Durabak, and SeaDek, followed by Epifanes Nonskid Deckcoating, Interlux Interdeck, and the Awlgrip Griptex additive. The two mats and West Marines SeaGloss Pro, Interdeck, and Pettit EZ-Decks offered the best grip when the surfaces were wet.

Taking into account all of the ratings and test results, the Durabak, Epifanes, and Interdeck were the all-star paints, and the Awlgrip and Interlux Intergrip were the top additives overall. The Awlgrip, Epifanes paint, and Interdeck also were the leaders among the fine-grit test products. Durabak was the only coarse-grit product tested.

The larger and sharper the grit, the less friendly it is to an inadvertent fall or lounging on deck. Durabak, Pettit EZ-Decks, and West Marines SeaGloss Pro were the roughest on testers knees and elbows, but all of the test finishes were acceptable on bare feet. While a fine, sand-like grit is the least abrasive to skin, it tends to offer less grip. The best aggregate for grip is coarse, sharp-edge grit, but it also can be more challenging to apply with uniform coverage.

Not surprisingly, testers found that the lighter colored paints like beige and white showed more dirt than darker colors like gray. Prospective nonskid shoppers should keep in mind that the same rules for choosing a topside paint color apply to choosing deck paints. White and light-colored or high-gloss paints will give more glare and are tougher to keep clean, but dark paints will absorb more UV, making them hot under bare feet. The pre-mixed paints typically offer fewer color choices than you would have if you bought a separate additive and a deck paint, but the nonskid mats-depending on the manufacturer-seem to come in an endless rainbow of colors and patterns.

Mats are also the most expensive of the DIY nonskid options while the pre-mixed paints are the least expensive. The cost of applying an additive and a deck paint depends greatly on the paint you choose: A two-part polyurethane is more expensive than a mono-urethane or an enamel, but it also will last longer. (See our long-term topside paint test report in the February 2011 issue.) To get the most life out of a one-part deck coating, many pros use a two-part epoxy primer.

Grit-free Paint

KiwiGrip

KiwiGrip, an acrylic polymer manufactured by Seattle-based Pachena, was unique among the test paints because the paint doesn’t rely on filler media to achieve slip resistance. Instead, the coating gets its nonskid texture via application with the companys supplied Loopy Goopy roller sleeves, which have an uncommon nap. No suspended grit in the formula means no worries about the coating wearing through and the aggregate falling out over time.

The KiwiGrip instructions are clear, easy to follow, and offer multiple tips on ways to tailor the finish to match the users needs. Various techniques can yield sharp or rounded edges on the raised texture, and the faster the coating dries, the sharper the edges. The finish on our test panel-which was applied on an 85-degree fall day in Florida-had a stippled, sharp-looking texture, but testers found it surprisingly non-abrasive to skin.

KiwiGrip was easy to apply, and because its water-based, all thats needed for cleanup is soap and water. The KiwiGrip panel rated Good- for ease of cleaning, but it was a top performer in the grip and resistance tests, finishing in a four-way tie for third-best traction properties, with only the nonskid mats besting it in the inclined grip test.

Bottom line: At $40 per quart, KiwiGrip is a Recommended paint. Testers liked the fact that users can customize the grit to suit their needs and that they need not worry about the coating shedding aggregate as it weathers.

Pre-mixed Paints

Durabak

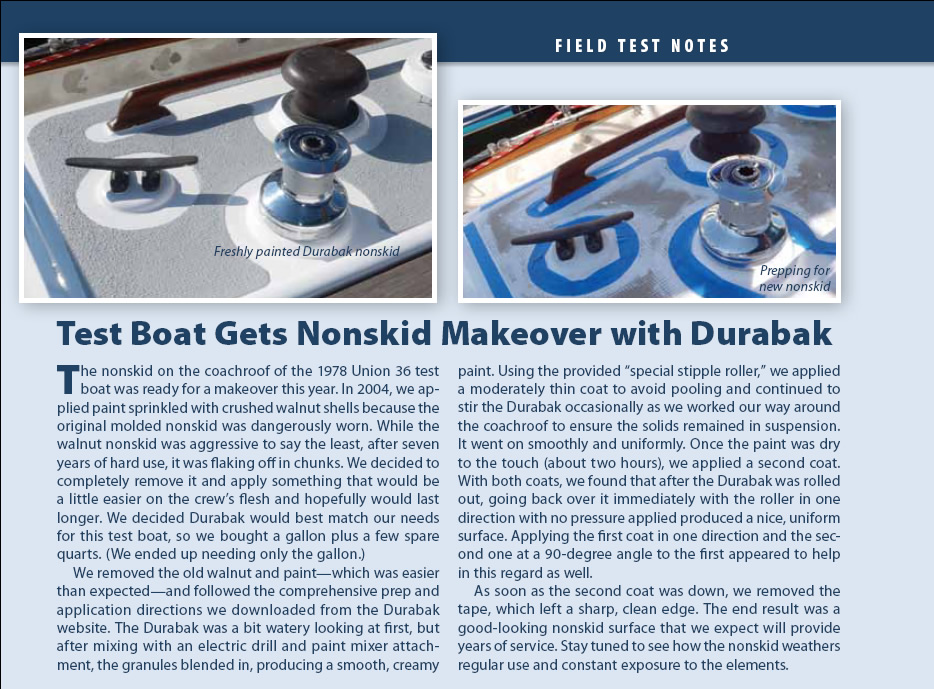

Another newcomer to Practical Sailor testing, Durabak is manufactured by a Colorado-based company that claims the coating lets you walk on water. While the slogan may seem a little over the top, Durabak led the pack among paints and additives in our resistance tests.

The tough, flexible polyurethane coating is pre-mixed with specially treated rubber granules. This coarse aggregate is no doubt why 10.6 pounds of pull were needed to drag the weighted tread across the Durabak test panel. Only the Treadmaster mat matched Durabak in resistance. It was also one of the products that tied for best traction among paints and additives.

While Durabak was a little rough on knees, the hard polyurethane will likely endure many years of service. Its maker claims the coating resists salt water, fuel, and chemical damage. It was easy to clean and even easier to apply-just mix and roll on-and achieving a uniform grit was effortless. We also applied Durabak to the deck of one of the PS test boats. See Field Test Results to find out how the real-world application went.

Starting at $120 per gallon, Durabak was one of the least expensive paints. It comes in more than a dozen colors.

Bottom line: Durabak polyurethane is a hard coating with many color choices and above-average traction at an affordable price. It gets the nod for PS Best Choice among paints and additives.

Epifanes Nonskid Deckcoating

Epifanes is an international marine coatings company with its North American office in Maine. Its Nonskid Deckcoating is a one-part, urethane-alkyd-based paint pre-mixed with polypropylene beads. Epifanes also sells the beads separately as an additive.

Testers noted that the semi-gloss paint came with clear instructions, was easy to work with, and coated the panel well, earning an Excellent for ease of application despite its 24-hour re-coat time, which was the longest of the test paints.

Epifanes paint was one of the better performers in the resistance tests but not the inclined grip test. Overall, it tied with three other products for second-best traction among the paints and additives.

One of the most expensive pre-mixed paints we tested ($47 for 750 milliliters, or three-fourths of a quart), Epifanes Nonskid Deckcoating comes in four basic colors.

Bottom line: Epifanes Deckcoating was kept out of the winners circle by slightly less-than-stellar grip test results, but it is a quality product. (This was a very tight race.)

Interlux Interdeck

Made by New Jersey-based Interlux Yacht Paints (part of the AkzoNobel family of companies), Interdeck is a polyurethane resin that is pre-mixed with a fine quartz additive and designed to protect decks against everyday wear and tear.

Interdecks fine aggregate yields an extremely smooth, uniform finish with tiny, sand-size grit. To have so little visible grit, the paint did surprisingly well in the incline test: It was among the top paint and additive grippers.

It also rated highly for ease of application, as did most of the other pre-mixed paints. In the cleaning test, a pass with the hose washed away all but a few ground-in soil scuffs, which required some brush-scrubbing to get off.

Available in five pastel and light colors, Interdeck is formulated to have a very-low gloss to keep glare to a minimum even with the lightest paints. At $30 per quart, Interdeck was one of the least pricey products we tested.

Bottom line: A notable performer at a bargain price, Interdeck gets the PS Budget Buy pick for paints.

Pettit EZ-Decks

Manufactured by the New Jersey-based Pettit Paints, EZ-Decks is a single-part polyurethane formulated to be easy to apply and resistant to abrasion and UV damage. While testers noted that EZ-Decks was indeed easy to roll on, they rated it Good for ease of application because the instructions advise giving it a week to cure. Most of the other products we tested needed only 24 hours to cure, but in Floridas high humidity, the EZ-Decks panel took about eight days to fully set. This is a significant consideration for those in humid climates who have limited time to allow the finish to set up.

Overall, the EZ-Decks was an average performer, notching Fair ratings for skin abrasion and cleaning ease, which was no surprise as it was one of only two medium-grit paints that we tested. After a pass with a garden hose and a soft boat brush, the panel still had some soil scuffs on the raised aggregate.

Testers also reported that the medium-grit non-slip coating was one of the best for grip when testers tootsies were shoeless and when the surface was wet.

Pettits EZ-Decks runs about $40 per quart and is available in three colors.

Bottom line: EZ-Decks is a mid-priced, mid-performer among the pre-mixed paints we tested.

West Marine SeaGloss Pro

Made by Pettit but marketed by marine retail giant West Marine, SeaGloss Pro is a single-part polyurethane/silicone alkyd enamel pre-mixed with a nonskid compound of polypropylene beads. According to West Marine, it is formulated to have improved color stability, abrasion resistance, and chemical resistance.

Testers had the same curing issue with the SeaGloss Pro that we had with the Pettit pre-mixed paint. Even after eight days of dry/cure time, the SeaGloss panel had paint peel off the grit once testers stepped on it. We gave it a few more days to cure before testing.

The SeaGloss Pro showed Good grip in the incline test, but when it came to cleaning and skin abrasion, its ratings slid to the Fair category. The panel still looked dirty, mainly on raised spots, after hosing and soft scrubbing.

With a $35 per quart pricetag, SeaGloss Pro is at the lower end of the price spectrum. It is available in four colors.

Bottom line: SeaGloss is a middle of the road performer at an affordable price.

Paint Additives

Awlgrip Griptex

One of the AkzoNobel companies, Awlgrip’s nonskid additive, Griptex, is a polymer bead aggregate that comes in fine, coarse, and extra coarse. We tested the fine grit in this evaluation, but testers have had great results in the past using the Griptex extra coarse for high-traction needs on test boats and the Griptex coarse for a more skin-friendly finish with good grip.

For testing, we mixed the Griptex with Interluxs high-gloss, two-part poly-urethane Perfection. Like all of the additives tested, Griptex earned a Good rating for ease of application. With proper mixing, it was easy to attain a near-excellent uniform grit pattern. As with all Awlgrip products, Griptex is maker-recommended for professional use only, but we see no reason why even a novice couldnt apply it properly.

Griptex was one of the top-rated additives for traction, but the fine grit wasnt as grippy during incline testing as the mats or some pre-mixed paints.

With a $34 pricetag, Griptex is a mid-priced additive the among test products. The total cost of applying it will ultimately depend on which paint you mix it with. Awlgrip recommends Awlgrip or Awlcraft 2000 topcoat paints.

Bottom line: Griptex is a PS Recommended additive. Its affordable and offers decent slip resistance. For the best traction, we suggest using the coarse or extra-coarse grit.

Epifanes Bead Additive

A polymer-bead compound, Epifanes additive is sold pre-measured for adding to Epifanes polyurethane and monourethane paints. We added it to the Epifanes polyurethane for testing.

The fine-grit media resulted in a very smooth finish that had the least resistance of any additive tested-on par with EZ-Decks and SeaGloss Pro paints. In grip tests, it matched Awlgrip and bested Intergrip but was a step behind the mats and some pre-mixed paints. As weve mentioned, a broadcast application would allow users to bump up the amount of aggregate to achieve a more slip-resistant finish-stay tuned for our follow-up report on this.

The Epifanes additive was fairly easy on bare skin and easy to clean. Several dirt scuffs remained after hosing off, but they easily brushed clean.

Priced at $51 for three-fourths of a quart (750 milliliters), the Epifanes was the priciest additive tested.

Bottom line: In such a closely matched test, it comes down to the smallest things to separate products. Epifanes additive was held back only by its slightly lower traction test results and its price, but it would be a good choice for those using Epifanes-brand deck paints.

Interlux Intergrip

Testers mixed the Intergrip polypropylene beads with Perfection paint, an easy to apply topcoat that would be a good candidate for re-coating an entire deck. (For more on Perfection, check out our polyurethane faceoff field test in the August 2009 issue.)

According to Interlux, the Intergrip spheres are less likely to collect dirt because of their regular shape. Intergrip rated Good for ease of cleaning, as did the other two additives tested.

With a fine grit and super smooth finish-seemingly the smoothest of all coatings tested-Intergrip was easier on elbows and knees than any other additive. And while it had a better resistance-test showing than the other additives, it had less grip.

Priced at $23 per quart, the Intergrip beads were the cheapest product tested.

Bottom line: For those who prize skin-friendliness over ultra-grippiness, Intergrip is worth considering. Its rock-bottom price earns it the PS Budget Buy among additives.

Matsd

Treadmaster

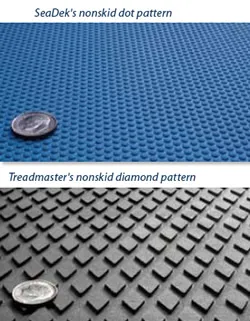

The nitrile rubber/PVC Treadmaster mat, made by UK-based Tiflex, was PSs top pick among nonskid mats in the Feb. 1, 2003 and Nov. 1, 1995 evaluations-and for good reason. Its slip resistance is unparalleled. The original diamond pattern allowed testers to stay sure-footed beyond 50 degrees of incline in all but one test situation. It also tied with Durabak for having the most resistance.

The only areas where Treadmaster was led by the SeaDek mat were application and skin abrasion, by a hair. The Treadmaster, which was harder than the squishy SeaDek, was a little rougher on knees, and the heavier, trimmable mat was harder to glue on than the self adhesive, pre-cut SeaDek.

Testers applied Treadmaster with its proprietary two-part epoxy, an insanely strong adhesive that has about an hour of workable pot life before it becomes permanently stuck to whatever its touching. During our application, some glue oozed out from the panel edge and onto our shops concrete floor. When we removed the dried epoxy from the floor, chunks of concrete came with it. Lesson learned: Clean up any errant epoxy with a solvent as soon as possible, and as directed, be sure to leave a lip around the mat edge that is free of glue; the epoxy will squeeze into the bare area when the mat is put in place.

Made of ground cork and nitrile rubber, Treadmaster is designed to resist stretch, wear and tear, and chemical damage. Testers found it surprisingly easy to clean. Treadmaster can handle cleaning with a pressure washer, but our test panel went from mud-caked to spotless with a quick once-over with a garden hose. We expected the deep crannies between the diamonds to trap dirt, but it washed away easily. However, testers did note that the pattern sometimes trapped pea-size gravel.

It comes in eight-plus colors. Prices vary by sheet size, but re-fitting the whole deck with Treadmaster would definitely be more expensive than painting it.

Bottom line: Treadmaster remains King of the Mats. It’s the PS Best Choice.

SeaDek

Made by Hyperform Inc., a Florida company, SeaDek mats are manufactured in the U.S. from nonabsorbent, closed-cell EVA material. The SeaDek dot-pattern offered Excellent grip-only Treadmaster out-performed it in incline tests-and top-notch traction.

SeaDek was by far the easiest test product to apply: Peel the backing off the pre-cut pad and stick it on the deck, and youre done. The adhesive, according to SeaDek, is marine grade and long-lasting. The pre-cut pads have beveled edges, but various size sheets are available with unfinished edges for self-trimming.

SeaDek mats are noticeably softer than Treadmaster, making them a great choice for placing on a swim platform or where crew sit frequently. The EVA foam acts as a shock absorber as well, so a pad placed on the cockpit sole can make long stints at the helm easier on the legs and back.

The rubbery softness has its drawbacks though: It punctured easily during tests, raising questions about its long-term durability and its practical use as an all-over deck nonskid.

Prices vary depending on sheet size. SeaDek is available in 20-plus colors and patterns, including camouflage and teak.

Bottom line: The soft, grippy SeaDek felt great underfoot, but its tendency to puncture easily makes us hesitant to recommend it. While we would caution against installing it near an anchor or other sharp, heavy objects, gluing a small SeaDek pad near the helm or in the cockpit floor has real benefit.

Conclusions

Choosing which type of nonskid is the right one for your boat makeover is a balancing act between aesthetic taste, traction needs, and budget. The bold look of a patterned mat may not suit the classic boat owner, and the cost wont match everyones budgets. However, they do offer the best grip and wont shed gripping media over time.

Treadmaster is our Best Choice. Its pricier than pre-mixed paints and additives and will add weight to your boat that paints wont, but it’s easy to apply, easy to clean, and the grippiest of them all. Its also the most permanent; removing the epoxy would be a nightmare, so be sure its what you want and where you want it before you glue it to your deck.

If a pre-mixed paint with superior grip is more your bag, Durabak is a good bet, but keep in mind that its not very friendly to bare skin. Our pick for a less knee-shredding paint with decent grip would be KiwiGrip or the Budget Buy Interlux Interdeck.

Boat owners who want the ability to customize their nonskid application and want to choose their own deck paint would do well with the Awlgrip additive; choose the grit thats right for your application. The Budget Buy Intergrip additive offers a good compromise between grip and skin abrasion. In instances where a company sells a pre-mixed paint and a nonskid additive using the same media, as Epifanes does, wed likely use both products, applying the paint and sifting extra aggregate over it. This would likely save money and time in the long run.