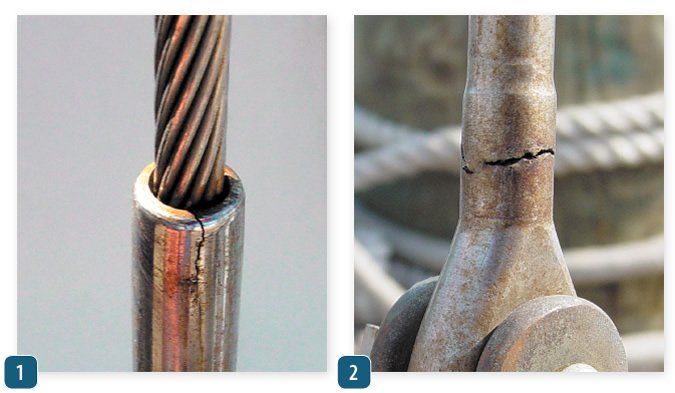

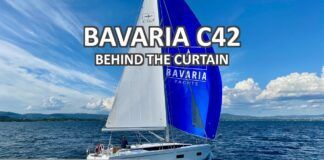

Here are two good examples showing the problems associated with the lower or deck level use of swage terminals for your standing rigging. Swaging is a process where tubular stainless steel fittings are essentially crimped onto rigging wire under high pressure.

Swage fittings are popular for a number of reasons. Theyre cost effective (i.e. cheaper) and in northern latitudes they can last a good long time (15 to 20 plus years is not uncommon). They don’t do as well in southern latitudes however, where they tend to fail faster due to temperature and increased salinity.

Salt water and other corrosive elements run down the wire and migrate into the fitting. This initiates rust, which expands and eventually causes the shank of the swage to rupture (as shown in image 1) allowing the wire to unexpectedly pull free. While vertical cracks in swaged fittings are bad enough, the horizontal crack shown in image 2 is worse.

Horizontal cracks are generally caused by metal fatigue, rather than internal corrosion. Such fittings have no safety margin and must be replaced immediately. If you find either type of swage terminal failure, youll not only want to address it immediately, but also inspect the rest of your standing rigging prior to vessel use. The remainder of your fittings are likely the same age and prone to similar failure.

An excellent alternative to swage terminals are mechanical fittings, such as Sta-Loc, Norseman or Hi-Mod. Mechanical fittings grip the wire via a conical wedge inserted into the center of the wire and fitting body that covers it. This type of connection results in reduced corrosion and less chance of failure. Mechanical fittings are more expensive than swage fittings, but have the added benefit of being reusable.

If you crave the reliability of mechanical fittings for your standing rigging, but baulk at spending the extra money to use them exclusively, an acceptable compromise is to use swaged fittings for the upper terminals and mechanical fittings for the lower ends. Since most problems with swaged fittings occur at the deck fittings, this strategy gives you the best of both worlds. See the online version of this article features for links to PS articles on swage inspection and installation, plus results from our most recent test of mechanical fittings.

Capt. Frank Lanier is an accredited marine surveyor with over 30 years of experience in the marine industry. He is the author of Jack Tar and the Baboon Watch: A Guide to Curious Nautical Knowledge for Landlubbers and Sea Lawyers Alike. His website is http://www.captfklanier.com.

New shrouds with swage fittings 2 years ago for my 1999 Alerion 28. Already seeing rust on top of swages.

Boat is at protected dock and rinsed every day. Can I put some sealer or clear nail polish on swage top??