Movies can be corny, but Jack Sparrow nicely summarized the romance of sailing: “That’s what a ship is, you know. Is not just a keel and a hull and a deck and sails, that’s what a ship needs but what a ship is … what the Black Pearl really is… is freedom.”

And in addition to the basics of hull, deck, and sail, the freedom to anchor out whenever and wherever we chose requires good ground tackle and enough electricity to keep the lights burning and fans turning. Generators are practical and wind turbines produce high output, but solar is silent, allowing you to enjoy one of sailing’s other pleasures: a quiet lagoon, with only the sound of wind, wave, and birds. In this report well compare the three main types of panels, rigid, semi-rigid, and flexible.

ENERGY BUDGET

The starting point for a successful power installation is quantifying what you need. The online version of this article links to a simple analysis. The analysis includes some rule-of-thumb estimates as well as actual data.

Energy Balance. Look up the current draw of each piece of equipment (confirm with your panel ammeter if available) and estimate the number of hours operated. Record the number and capacity of your batteries, recognizing that only 35 percent of nameplate capacity is really usable because you can’t draw below 50 percent charge without shortening the battery life, and that a complete charge while away from the dock is difficult to achieve.

Finally, total your charging sources, including engine, wind, and solar. For solar, take the rated wattage x 5 hours/12 = amp-hours while on passage and wattage x 7 hours/12 = amp-hours while at anchor (sails do not shade and the boom can be rigged out to the side). This is far below the rated capacity for the solar panel sailors use in the tropics. They will do better, and sailors farther north or sailing in the winter more poorly. But this is an accepted starting point. When estimating, also take into account the effect of shade on output.

Panel square to full sun:

100 percent output.

Panel at 45-degrees to full to sun:

71 percent output

Light overcast: 20-70 percent output

Heavy overcast: 10-20 percent output

How many days can you manage with poor solar-power generation? Are you willing to economize during a long cloudy stretch? Will you recharge at a marina or by running the engine periodically? Long-term cruisers appreciate an abundance of power, while the occasional cruisers may be satisfied with less.

Saving Power. Every Ah (amp-hour) consumed has a real cost in weight, panels, and dollars. If you can reduce consumption by 50 Ah/day you will save the cost of a bigger battery, a 120-watt panel, and perhaps a mounting arch. The cost savings might be $500 and 150 pounds for just a few bulbs.

Lighting. Switch from incandescent to LED and fluorescent lighting, starting with the lights you use most. LEDs and fluorescent lights can replace the anchor, salon, and cockpit lights. Passagemakers will save amps with LED running lights. Switching to LED deck lights isn’t a top priority, but their low consumption means there is one less worry when you need them through the night.

Adjust your schedule. Go to bed at night and get up with the sun. It will mean big savings in juice and more time to play.

Turn off unused equipment. The gas solenoid runs the propane fridge and cabin heater on one of our test boats (a catamaran), so it is on for long hours, but we can close the propane bottle valves and turn it off occasionally.

Run fans on low speed. A wind scoop doesn’t use power.

Watch electronics. Radar is the big energy hog, but new pulse compression radar options is changing that. Balance the sails to minimize load on the autopilot.

PANEL SELECTION

Nominal 12-volt panels will typically have an open circuit (OC) voltage of 20-22 volts and a MPP (maximum power point) of 15-18 volts. Lower voltage panels must be wired in series to reach the required voltage range; the charge controller can then regulate this as need to charge the batteries.

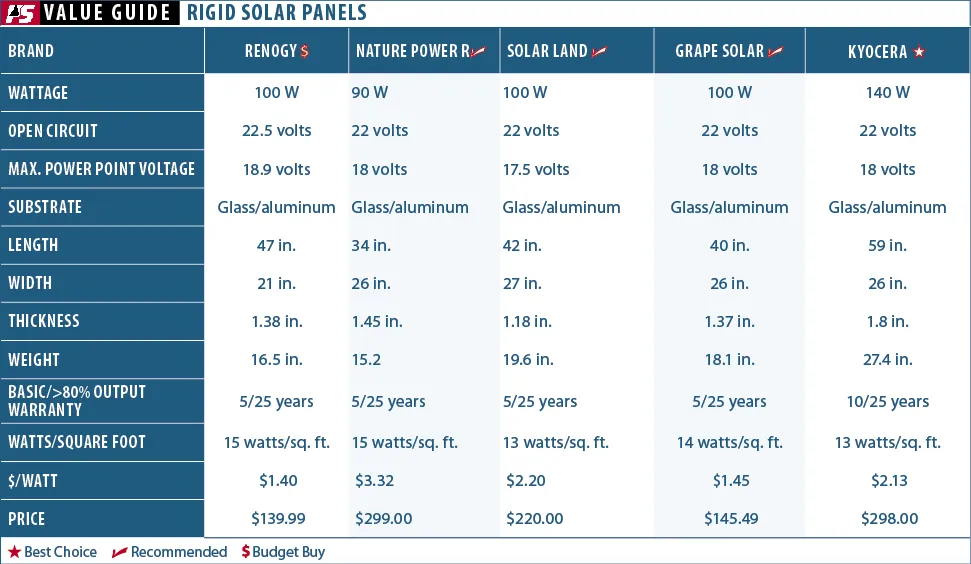

Rigid panels have long been the gold standard. Output declines very slowly over 20-plus years, generation per unit area is high, failures are very rare, and the cost per watt is low, particularly in larger sizes.

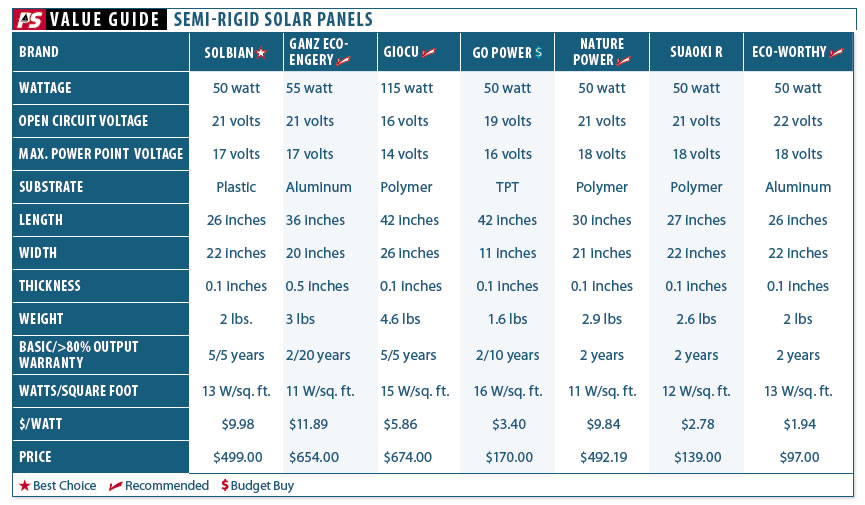

On the downside, they are bulky, heavy, require custom mounting, and will break if struck. Semi-flexible panels are light, conform to the moderate curves, and contribute no windage, but they cost more and deteriorate sooner, with only a 2-to 5-year output warranty, and at best a 10-year useful life.

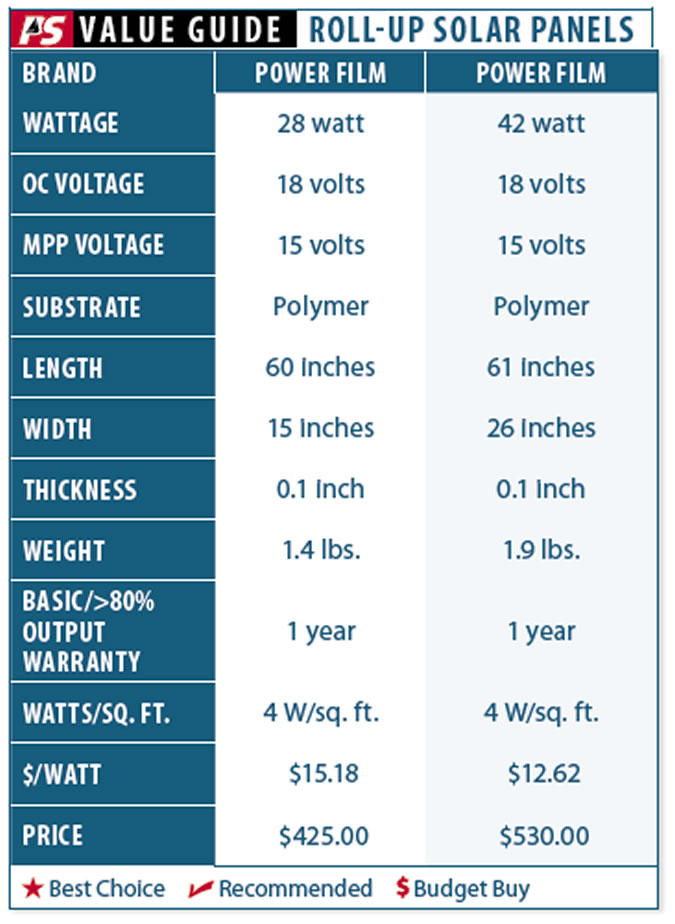

Roll-up panels can fit anywhere and are more shade tolerant, but they cost far more per watt, generate 70 percent less power for a given area, and life expectancy is 5 years or less.

It boils down to available space, tolerance for weight and windage, and budget; often several types can be used on a single boat, each best for its location.

WHAT WE TESTED

Our experience and the experience of installers is that nearly all panels—excluding some very low end junk—meet manufacture output specifications when new. Premature failures of rigid panels are very rare, even among low-priced Chinese imports.

For the rigid panels, we compared third-party output specs used for certification, interviewed users and installers for information about panels that have a good track record and US distribution, and then narrowed the focus to only the most highly recommended.

Several brands of inexpensive semi-rigid panels have appeared on the market. Because of the limited data on these cheaper semi-rigid panels, we are putting some of those into long-term test, which is still ongoing. Roll-up panels received so few recommendation from our panel of experts that we did not include them in our long-term comparison.

For this report, we focused on identifying the most desirable features and potential trouble spots. Before investing in a new panel, we encourage readers to examine all available information to see if it conforms with the following recommendations:

RIGID PANELS

Performance over time is primarily intrinsic to the cell material and is very similar for all makers; expect a 1-2 percent loss in output per year. Other common losses include shading, dirty panels, and undersize wires. The junction box must be well potted to the panel underside and the wire pass-throughs must be well sealed. Poor mounting can result in flexing, leading to delamination and sealing failures. Although panels seem quite stiff, sailing loads can bend the glass and frame.

RIGID PANEL CHECKLIST

Rigid aluminum frame. Better quality panels will use extruded frames with hollow spaces to increase rigidity at a given weight, while low-cost panels may use a simple channel, providing less support to the glass. Kyocera takes the heavy-weight approach, and the result is a strong panel. Lightweight panels can also be perfectly acceptable if you provided a well-designed mounting frame that minimizes stress on the panel. Supporting the length of the panel with aluminum angle works well.

Good sealing around all the edges. If something is beginning to separate or shows any evidence of delamination, return it immediately.

Junction boxes. These need to be well sealed to the panel.

Terminal strip inside junction box. While the standard M4 plugs are adequate, having a high quality terminal strip inside a well-sealed junction box makes it convenient to run the power from multiple panels to a common point.

Good sealing of all wire pass-throughs. A compression fitting is best, but neat caulking can be acceptable.

Voltage, open circuit. This is usually 20-23 volts for parallel wired panels led to conventional controllers (typically pulse width modulation). Higher is acceptable for MPPT controllers, up to the controller limit. Lower voltage can lead to very low output both on cloudy days and once the battery state of charge passes 50 percent. Typically, lower voltage panels are made with fewer cells (32 versus the standard 36 cells) and are often called self-regulating.

Blocking diodes. These prevent panel damage and power loss from the electrical equivalent of backflow when the panel is shaded. Although the diodes causes some voltage drop and output loss, it is a worthwhile compromise. These are standard on virtually all panels.

SEMI-RIGID PANELS

A semi-rigid panel is basically a rigid panel without its armor. The cells themselves have always been slightly flexible, just as thin glass can bend within limits, and this new packaging aims to take advantage of that characteristic, doing away with bulky protection, but it demands that the user understand the limitations. Glass has been replaced with thin acrylic that provides less structural support and is more vulnerable to UV damage than typical hatch glazing. Because it must be transparent to UV light, it cannot have the usual UV protective film used to block damaging rays in the 300-400 nm range.

Stiff aluminum rails have been replaced by a thin sheet of aluminum, fiberglass, or thermoplastic. Sturdy junction boxes have been replaced by tiny boxes that often suffer from chafe, and panels that are mounted on solid surfaces are subject to overheating because they don’t allow for air to flow beneath them. We found it interesting that the most established producers had the very detailed caution statements in the installation manuals; clearly stating that these panels require firm, non-flexing support. Although semi-rigid panels can tolerate gentle curves, all the brands we investigated have failed when bent repeatedly.

Cupping. If mounted to an insulated surface (not a Bimini top), semi-rigid panels can overheat and cup. More substantial backing materials (aluminum or G10) prevent this. Allowing air under the panel also works.

No vigorous polishing. Rubbing causes flexing, and flexing causes micro-cracks in the cells that can rapidly reduce panel output. Light cleaning only.

Over-bending. While these panels can conform to very gentle curves, they do not like pressure points. Point loads from metal Bimini supports have caused several failures. Panels that may be stepped on must be very well supported, without ridges, wires, or fittings underneath. Generally, walk-on panels are a bad idea.

Delamination. Examine the panels VERY carefully for delamination when received. If there is any sign of peeling, return them.

SEMI-RIGID PANEL CHECKLIST

Lamination. Since the primary cause of failure is delamination, examine all edges carefully.

Substrate. Both aluminum and polymer backings are common, the stiffer the better. The cells on the cheapest panels are protected by only a thin sheet of PVA, while Solbian and Ganz panels use more substantial materials. However, even the best panels come with extensive warnings regarding mounting and rough handling. They are all delicate.

Mounting. If you have a smooth deck and can simply attach them with Velcro (3M Releasable Extreme Fasteners, also known as Dual Lock), adhesive, or screws, it will be simple. If you need provide supplemental support they may be as difficult to install as rigid panels.

THE OFF SEASON

There are two schools of thought on this. The first group disconnects all loads, confirms the battery electrolyte is topped off, and leaves the panels and controller in operation (the output will drop to zero when covered with snow). The other group fears over-charging due to battery or charger failure, and disconnects the panels. A few take a middle road, leaving one panel connected.

CONCLUSIONS

Solar seems like an obvious choice for the cruising sailor: reasonable cost, long life, light-weight, zero maintenance, and quiet. However, like the better, faster, cheaper myth, you can have just two out of the first three. The rigid versus semi-rigid choice is not so cut and dried. Rigid panels last longer and cost less, but are heavier, and can be complex to mount, particularly if an extensive frame or arch is required. Semi-rigid panels are light, have low-windage, and are generally easier to mount, but there are numerous rules that must be followed and their life expectancy is less. Roll-up panels take this compromise further, with lay-anywhere mounting, but high cost, low power output and limited life.

For many, a good compromise is to mount rigid panels where there are natural places—hard-tops, open deck, pre-existing arches, hard dodgers, and davits—and fill any remaining needs with semi-flexible panels. Building arches or bulky frames for the sole purpose of adding rigid panels adds windage, weight, and obstruction.

Great article. I did my solar system in 2016. I used 2- 250-watt Sanyo ridged panels with an Outback MTTP controller. This is connected to 8 Trojan T-105 batteries. Maybe this is a little overkill for our 33′ boat but the system has been perfect & and absolutely trouble free. To do over again I would have used AGM or maintenance free batteries. Your article lists per watt prices. We bought ours for $0.49 per watt. I have nothing to do with this company except being a satisfied customer. The company is Sun Electronics in Miami Fl. After a lot of searching this company had the best pricing and customer service.

GREAT ARTICLE AS USUAL. I’m a Daysailor on my Alerion 28 Express. The dock at my marina on Lake Michigan does not have shore power, just a lot of sailors. BTW the seasonal cost is waaaay less expensive when you give up creature comforts like that. I use a nice roll-up panel for the 2 house batteries and a rigid one on the dock box. Why do I need power to the dock box? Simple. The dock also doesn’t have running water. Another money saver but doing a wash down and hauling buckets of water aboard isn’t my idea of fun. So, I installed a 12-volt washdown pump in the box – not on our boat – with a 12-volt battery, and a small hole drilled through the dock to slip an 8-foot length of hose into the fresh water. What keeps the hose from floating to the surface? Simple. A Sacrificial zinc clamped on the hose. It’s lasted over 10 years now!

I just checked the eMarine Systems web site and it states: Kyocera Solar PV Panels Are No Longer Available. Why is PS reviewing a product that is no longer available?

What a fantastic article! My only bone of contention would be that the 50% of the battery bank’s capacity being usable only applies to lead/acid batteries. It does NOT apply to Lithium, but it is STILL unwise to go under 15%, as damage to the cells may result.

Why is the unit for weight of the rigid panels “in.”? I assume it should be lbs.

Re. Weight. That was an editing error. It is pounds, of course.