Over the last two years, Practical Sailor has dug deeply into ways to keep gasoline and diesel fuel tanks healthy. Weve investigated ethanol phase separation, anti-corrosion additives, biocides, and gasoline-tank vent filters (PS, January 2013, February 2013, and August 2013). We’ve learned that while effective additives can help, the bottom line is that clean, dry fuel is the only sure path to fuel-system protection and reliability.

The most common way for water to contaminate fuel is through leaky fill caps-this is particularly disconcerting because corrosive salt water is in the mix. Boat owners should inspect the fill cap O-ring regularly, and replace it early. A light coating of Vaseline will prevent sticking and help repel water. Any flowing water-rain or sea water-should be diverted away from the cap with rails or by relocating the fill cap.

Wet fuel can also come from the fuel dock as either free water or as water-saturated fuel. Neither should be surprising, given how many coastal tanks have gone under during storms.

Water can also enter through the fuel tanks daily vent breathing. In the January 2013 issue, testing showed that free water can condense and fall to the bottom of fuel tanks, primarily in cool, damp weather, but we also know that substantial dissolved water can be present in warmer temperatures-not visible, but still working its mischief. During long winter storage, perhaps, daily breathing is the most significant cause of water getting into fuel. It is this water source that can be stemmed by installing a fuel-tank vent filter.

Through lab tests and several years of field testing, we’ve found that silica-gel vent filters reduce tank corrosion and improve gasoline stability. But is the same true for diesel fuel and tanks? Thats what this test sought to find out.

What We Tested

When we launched this test, there was only one vendor of diesel vent filters marketed for marine use, Pindell Engineering. The first in the marine desiccan’t business, Pindell offers its diesel tank vent filter in two models: the AVD2 for tanks up to 60 gallons and the AVD3 for tanks up to 200 gallons. The AVD2 contains 17 ounces of silica gel, and the AVD3 has 34 ounces.

The AVD filters are suitable for diesel or gasoline, and the H2Out AVD2 was testers Best Choice pick in our recent test of gas tank vent filters.

The filters can be installed in any orientation. The silica gel changes from blue resin to pink once about 70 percent of the available adsorption capacity is spent. The color change is easy to see through the housings clear Lexan shell. To remove the spent silica, simply remove a hose clamp on one end and dump it out, but doing this neatly requires removing the housing from the line in most installations. The AVD2 retails for $129, and the AVD3 costs $189. Refills, available through Pindell, cost $30 for the AVD2 and $40 for the AVD3.

Since that test, Vetus Engineering launched a new tank vent filter that would be compatible with diesel, as well as gas. Unlike the Vetus No-Smell NSF16 we tested in the gasoline filter comparison, the new No-Smell NSFCAN will use a combination of activated bulk carbon and bulk silica gel as its adsorbent media. This approach is similar to the experimental filter PS testers constructed for the gas filter test, using the NSF16 housing and bulk silica gel. We plan to test the new Vetus filter once it is released.

Could a sailor build his own fuel-tank vent filter? Because of safety issues and materials compatibility issues, we are going to leave that question to the engineers. PS testers used PVC pipe to construct mini filters for the test, but PVC should not be used in on-board installations; PVC glues do not adequately resist petroleum, and the no-hub, flexible PVC fittings available in hardware stores are not suitable for use with petroleum. Could a boat owner adapt an industrial version? Perhaps, but there are design issues that prevent our recommendation-they often contain fine filters that can plug and endanger the vent function; they are often designed only for vertical installation; and some are not diesel compatible.

How We Tested

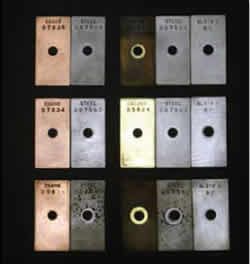

For lab testing, we selected a bundle of metal coupons (samples of standard alloys prepared into 1-inch by 2-inch rectangles with a hole in the center for mounting) used in ASTM method D1384, a method for evaluating engine coolants. We modified the ASTM test to serve our purposes. This approach ensures uniform metal alloys of known composition. Additionally, the coupon bundles are designed to mimic the galvanic corrosion effects common to units assembled from dissimilar metals. The couplings used were aluminum/steel/brass (to mimic a poorly assembled fuel system, since brass should not be coupled with aluminum, but we have seen it done) and copper/steel (to mimic a steel tank and typical fuel systems).

We filled three 1-liter bottles with 300 milliliters of ultra-low sulfur (ULS) diesel from a busy retailer, placing a metal corrosion bundle in each bottle. The tips of the coupons were left exposed to ensure some air exposure. One bottle was sealed to serve as a control; another was vented through 10 inches of 3/16-inch ID vinyl tubing; and one was vented through a PVC mini-vent filter containing 6 milliliters of commercial-grade silica gel (from H2Outs AVD3 vent filter) and a tail of 7 inches of 3/16-inch ID vinyl tubing. This laboratory vent filter was sized to be proportional to an ADV2 fitted to a 30-gallon tank; however, we exposed the samples to greater temperature swings (due to their small mass) and a shorter vent hose than real-world installations, creating a scenario where the vent filter began to fail during the shortened test period; seven months of exposure in our test setup is comparable to three to five years of real-world exposure. The tested vent filter was exposed until the silica gel was 70 percent spent, as shown by its color; this took from December through July in typical Chesapeake Bay-area weather.

To get some real-world data, testers installed two H2Out AVD3 vent filters aboard test boats equipped with 75- to 100-gallon fuel tanks; the boats are kept in the water year-round.

Lab Test Results

The photographs tell the story. The diesel fuel in the test setup with the vent filter remained clearer and contained less sediment than the free-vented or sealed samples. It seems that the silica gel actually dried the fuel, relative to the sealed sample-this was something we also observed in testing gasoline tank vent filters. There was a thin layer of pink, spent resin on the fuel-tank side of the filter, as well as a thick pink layer on the atmosphere side of the filter, with only a thin layer of blue resin separating the two.

The discoloration of the fuel was the result of the metal coupons corroding, which was due in part to the presence of air and water in the test setup. Another catalyst was the disproportionate amount of copper; copper can cause fuel to polymerize and gum.

While the discolored fuel was evidence enough of corrosion, the degradation of the metal coupons was more dramatic. Testers rated the sealed test sample as fair, and the sample with the vent filter was pristine, but the free-vented sample displayed serious corrosion, including major pitting of the steel coupons. The aluminum coupons were unaffected. The small size of the samples certainly exaggerates these trends, but the findings are very clear: Dry air and dry fuel mean less corrosion and less fuel deterioration.

Field Test Results

So far, our field-test data suggests that Pindell Engineerings recommendation that the desiccan’t media in the H2Out filters be replaced about once or twice per season, is extremely conservative. In one year, we have seen almost no color change in several installations, and we believe two to six years is possible, depending on the vent configuration, tank size, fueling practices, and geography.

These results are in stark contrast to our e-10 gasoline testing results, which indicated that the ethanol present enables the silica gel to self-regenerate, allowing one refill to last at least several years. However, the cost and effort to replace the gel in the H2Out filters is minimal. The clear polycarbonate filter housing makes it easy to inspect the silica gel and to see whether it has changed color. Silica-gel resin is available through Pindell Engineering or from commercial desiccant vendors at significant discount.

Conclusion

The H2Out AVD vent-filter line performs well in diesel fuel systems, and the filters deliver value. Users will need to replace the media every few years, when the media color changes, at a cost of $15 (from Delta Adsorbents) to $40 (Pindell). The service cost can be justified as it can prevent a potential tank or engine repair down the road, then its financially smart. If on-the-water reliability matters, then its a very simple decision. An annual media inspection before winter storage would be a sound practice, as any remaining fuel will be sitting for a long period.

For a sailor who doesn’t burn through a single tank in a year or who doesn’t want to top off a tank with fuel that will only sit for another year and grow stale, a vent filter is one option, but full tanks help too. Anything you can do to preserve fuel quality is a benefit.