When the mega container ship Dali struck the Francis Scott Key Bridge at 1:28 am on Tuesday, March 26, the world saw a remote video of a ship-wide power outage seconds before impact.

Dali was propelled by a single low-speed two-stroke crosshead diesel engine coupled to a fixed-pitch propeller. The container ship’s 9-cylinder MAN-B&W 9S90ME-C9.2 unit, manufactured by Hyundai Heavy Industries under license, is rated at 41,480 kW (55,630 hp) at 82.5 rpm. The ship’s recorded service speed is 22 knots (41 km/h; 25 mph)

What had the power to take down a machine of Dali’s size and capability? Fuel contamination. The Dali’s predicament reminds those of us in the business of moving our own boats across the water that we are not immune from this kind of problem.

‘CRUD’ BY ANY OTHER NAME

A quick search reveals the different types of contaminants commonly found in diesel fuel. The list is long…and worrisome. It includes:

Water Contamination. Water can enter diesel fuel through condensation, leaks, or during handling and storage. It can exist in three forms:

- Dissolved Water: Water that is chemically dissolved in the fuel.

- Emulsified Water: Small droplets of water suspended in the diesel.

- Free Water: Water that separates and settles at the bottom of the fuel tank.

Microbial Growth. This refers to the growth of bacteria, fungi (molds and yeasts), and other microbes in the fuel, particularly where water is present. These organisms can form biofilms and sludge, which can block filters and corrode fuel system components.

Solid Particulate Contamination. This includes a variety of solid particles such as dust, grit, soot, rust, and engine wear particles that can enter the fuel during production, transport, or storage. These particulates can cause wear or damage to the fuel injection system and engine.

Asphaltenes. These are hard, insoluble particles that can form from changes in temperature and oxidation of the fuel. They can agglomerate into larger particles that block engine filters or damage injectors.

Gums and Other Organic Contaminants. The oxidation stability of biodiesel is inferior to that of petrochemical diesel, leading to the formation of peroxides, organic acids, and gummy sediment. These substances can adhere to fuel filters and engine components, causing corrosion and damage.

Microbial Contamination. Also known as the “diesel bug,” this includes numerous types of bacteria, molds, and yeasts that can affect unprotected diesel systems. The waste byproducts from these microbes can form sludge and contribute to corrosion within the fuel tank.

Fuel Degradation. Over time, especially if not stored properly, diesel fuel can degrade, leading to the development of tar and asphaltenes. This can darken the fuel and reduce its quality, potentially leading to engine problems.

Abrasives. These are hard particles like dust and dirt that can cause significant wear and tear on engine components due to their abrasive nature.

Fungi and Bacteria. These organisms can flourish in the presence of water and fuel, feeding on alkanes and additives, and producing sludge that can corrode steel tanks and degrade systems.

Additives. Sometimes, the additives mixed with diesel to improve its properties can also lead to contamination if not properly blended, or if they react adversely with other components in the fuel.

CRY HAVOC

Diesel fuel contamination can lead to a range of mechanical problems in diesel engines. These issues can affect various components of the engine and fuel system, leading to decreased performance, increased maintenance costs, and potentially severe engine damage. Problems include…

Clogged Filters. Contaminated diesel can contain particulates and microbial growth that can clog fuel filters, leading to reduced fuel flow and engine performance.

Damaged Fuel Injectors. Solid particulates, as well as water contamination, can cause wear and damage to fuel injectors. This can result in poor fuel atomization, decreased engine efficiency, and increased emissions.

Engine Component Wear. Contaminants like water and particulates in diesel fuel can cause abrasion and acidic erosion, leading to pitting and premature wear of engine components such as piston rings, cylinder linings, and intake valves.

Fuel System Corrosion. Water in diesel fuel can lead to corrosion within the fuel system, including the fuel tank and fuel lines, which can weaken these components and lead to leaks or failures.

Poor Engine Performance. Contaminated fuel can lead to a rise in fuel consumption, lower power output, and higher engine revolutions due to partial engine damage and reduced mechanical efficiency.

Increased Oil Consumption. Worn piston rings, which can be a result of fuel contamination, may allow oil to pass into the combustion chamber, leading to increased oil consumption and further contamination.

Excessive Smoke. Contaminated diesel can cause heavy smoke emissions from the exhaust, indicating incomplete combustion and the presence of unburnt contaminants.

Difficulties in Fuel Flow. Contaminated diesel can saturate primary and secondary filters prematurely, allowing excess contamination to pass through the system and hinder the correct flow of fuel.

Carbonization of Engine Parts. Contaminated fuel can lead to carbon buildup on the upper parts of the engine, such as rings, pistons, and cylinders, which can cause further damage and inefficiency.

Fuel Gauging Problems. Diesel bug buildup can cause issues with pump and injector wear, as well as metering and gauging problems, leading to inaccurate fuel level readings.

Injector Tip Explosion. In extreme cases, especially freezing ambient temperatures, water contamination can cause injector tips to explode due to poor lubrication.

THE ROLE OF FUEL ADDITIVES…AND FILTERS

Diesel fuel additives play a crucial role in maintaining the cleanliness and efficiency of diesel engines, contributing to fewer mechanical problems. These additives are designed to improve the fuel’s properties, ensuring better combustion, reducing emissions, and preventing various forms of contamination. Here are types of diesel fuel additives.

Fuel System Cleaners. These additives are designed to clean the fuel system, including injectors, fuel lines, and the combustion chamber. By removing dirt, debris, and other contaminants, fuel system cleaners help improve engine performance and fuel economy. Also, regularly check and replace filters, and address any signs of contamination promptly.

Cetane Boosters. Cetane boosters increase the cetane number of diesel fuel, which is a measure of the fuel’s ignition quality. Higher cetane numbers improve combustion efficiency, reduce engine noise, and decrease smoke emissions. This leads to smoother engine operation and reduced mechanical stress.

Lubricants. Diesel fuel lubricants are additives that reduce friction between moving parts in the engine. By minimizing friction, these additives help protect the engine from wear and tear, improve fuel efficiency, and extend the engine’s life.

Anti-Gel Additives. Cold temperatures can cause diesel fuel to gel, leading to clogged fuel filters and fuel lines. Anti-gel additives lower the temperature at which diesel fuel gels, ensuring proper fuel flow and preventing cold-start problems.

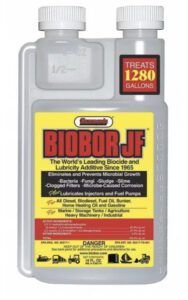

Biocides. Microbial contamination, or the “diesel bug,” can cause serious issues in diesel fuel systems. Biocides kill bacteria, fungi, and other microbes in the fuel, preventing the formation of sludge and acids that can corrode fuel system components and block filters.

Corrosion Inhibitors. These additives protect the fuel system from corrosion caused by water and other contaminants in the fuel. By preventing corrosion, these additives help maintain the integrity of the fuel system and extend its lifespan.

Stabilizers. Fuel stabilizers prevent the oxidation of diesel fuel during storage. Oxidation can lead to the formation of gums and varnishes that clog fuel injectors and degrade fuel quality. Stabilizers ensure that stored diesel fuel remains in good condition for longer periods.

Detergents. Detergent additives clean the fuel system by preventing the buildup of carbon deposits on injectors and other engine parts. This helps maintain optimal engine performance and fuel efficiency.

Dispersants. Dispersants help keep contaminants in diesel fuel suspended, preventing them from settling and forming deposits in the fuel system. This helps maintain clean fuel injectors and a clean combustion chamber.

Demulsifiers. Water in diesel fuel can lead to microbial growth and corrosion. Demulsifiers help separate water from diesel fuel, making it easier to remove water from the fuel system and prevent related issues.

It is important to regularly test and maintain diesel fuel to prevent these contaminants from causing mechanical issues. Using water separators, fuel additives, filters, and proper storage techniques can help mitigate the risks.

The Dali collision is a big wakeup call if fuel contamination is found to be the culprit.

I take issue with the statement “Dali was propelled by a single low-speed two-stroke crosshead diesel engine coupled to a fixed-pitch propeller.” Logic dictates that some sort of transmission device was placed between those two technologies. It is my understanding that the diesel engine spins and alternator that feeds an an electric motor that is connected to the propeller. The propeller shaft is the armature. That same arrangement has been in use on railroad diesel locomotives for decades.

MV Dali uses a directly connected MAN-B&W 9S90ME-C9.2 engine which is run in reverse for reverse propulsion. This arrangement is very common in Containerships.

Let’s not get ahead of the NTSB. While the press has advanced contaminated fuel as a possible cause, the on-going investigation has made no determinations. It will be some time before we understand why the Dali lost power.

While Dali may have instigated this article, the point is, any of us who run diesels can experience fuel contamination. I was overwhelmed to see all the types of additives that are out there. If I used them all, I wouldn’t have any room in my tank for the diesel fuel! So my question is: What one additive is best for maintaining a contaminant free fuel system and affected engine components?

My source for this info is a harbor pilot friend who undocked the MV Dali about two days before the Key bridge collision. He had docked and undocked her several times.

The Dali has a single large in-line diesel, as noted. There is no ‘neutral’. When the engine is turning, the prop is turning also. Reversing the engine (and proceeding astern) is done by stopping the engine, changing over the gear to select ‘astern’, and restarting the engine using compressed air. Whether the engine is then run in reverse is certainly possible. My point is that it is not instantly reversible.

Contaminated fuel is certainly a possibility. Apparently there are also a number of shipboard computers and it is possible that a cascade of failures begun by the failure of the main propulsion engine occurred, as successive systems shut down.

The pilot, who had very little time to react, was able to drop anchor, get off a MayDay call, and contact the MTA police to get all the traffic off the bridge- except for the road crew; six of the eight in the road crew died, which is tragic. But for the pilot’s action, more people might have died. That seems to me to be an admirable performance.

Interestingly, my friend felt that a tug escort should have been present and possibly cabled to the Dali. When the Dali left the dock, she was pushed off the dock by tugs, into the channel, and the main engine was then started. Apparently the main engine ran for at least a minute or two as she had accelerated to eight knots before the collision.

Like everyone here, I am very keen to see the findings of the NTSB and the USCG.