Photos by Drew Frye

The term whipping twine is somewhat misleading, suggesting a single purpose for a product with seemingly endless uses. These are the thin-woven strands that all hand-sewing projects depend upon, and in the process of exploring various stitching projects, weve gone through spools and spools of it.

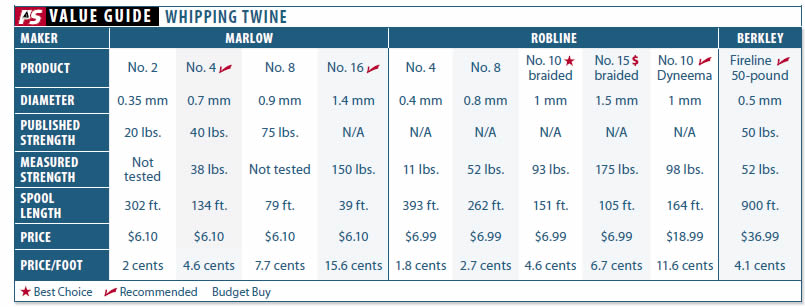

One of the things we were most interested in was the strength and effectiveness of various stitching methods. For this report, we looked at the twine itself. We measured how strong various twines were, and we learned which ones tangled the easiest. We also tested each type on our chafe machine to see which material best withstood the rigors of use.

How we tested

To determine strength, each twine was pulled to failure by wrapping it around a 1-inch drum and pulling four to 16 strands until breaking. (The number was adjusted as necessary to maintain steady loads on our test rig.) We conducted three trials for each product and averaged the results. Testers noted that there was some variability in each products ultimate breaking strengths-but not enough to upset the results.

The evaluations regarding ease of sewing and general performance were developed while sewing hundreds of eyes for the recent articles on sewn eyes and sewing webbing (see PS October 2014 online).

Abrasion testing was performed using a test rig developed by PS contributor Drew Frye to evaluate abrasion on rope. Sewn-eye splice samples (round-stitched) were abraded on both wood and grindstone surfaces for a fixed time (30 percent of the time required to wear through the rope cover). The twines were then pull tested for strength. Polyester twine samples were tested at 80 to 85 percent of initial design strength.

During abrasion testing, testers noted that the short duration of the abrasion test did not weaken the eye splices that were stitched with Dyneema twine. They extended the period of abrasion by 10-fold, and only then, were they able to produce some consistent failure points. It was clear that the Dyneema stitching actually extends the life of the spliced area by a considerable margin.

What We Tested

We focused on waxed polyester twine and unwaxed Dyneema twine. We also experimented with unwaxed polyester twine (we don’t think waxing it yourself is worth the effort) and Kevlar twine (good for high temperatures but too prone to fatigue failure for sailing use). Initial testing indicated that neither of these options were very practical when better options were so readily available, so we dropped them from further testing. Another test product we dropped from the final report was the Sherrill Tree waxed nylon twine. Although its perfect for lock-stitching double braid and burying splices in nylon rope where greater elasticity is desirable, nylon twine is wrong for every other sailing application as its too stretchy to serve much practical use.

Thread is numbered sequentially by size, but with whipping twine, this numbering system is not universal. One companys No. 6 may be thicker than another companys No. 8. Unlike fishing line companies, most marine manufacturers don’t give breaking strength; Marlow seems to be the exception. However, because strength tends to roughly coincide with line diameter for materials of the same dimensions, line diameter seems to be an acceptable guide for comparison. The trouble is, as we found, even the advertised diameters can be misleading.

You don’t need a micrometer to size twine when youre buying it. Simply, wrap the twine closely around a pen and count the strands in 1 centimeter. For sewn eyes, whipping, and very heavy sewing, match the thread size used in the cover (1 to 1.5 millimeters), and for canvas repair and smaller whippings, go a little lighter (0.6 to 0.8 millimeters).

FSE Robline Waxed Polyester

The No. 2 through No. 8 waxed whipping twines from Robline are laid polyester twine, rather than braided, while the Nos. 10 and 15 twines are more heavily waxed and braided, resulting in much better handling. An annoying characteristic of all laid twines is that as they are pulled through a thick material such as rope or webbing, the thread is twisted, causing tangles in doubled twine when lengths over 18 inches are used. Braided twine tangles far less, making sewing a more pleasant task. FSE Robline is available in Nos. 2, 4, 8, 10, and 15. The braided No. 10 was our favorite for heavy work.

Bottom line: Larger spools and ready availability make any of the Robline waxed polyester twines a good option. The braided No. 10 earns our Best Choice for excellent strength and ease of sewing. The No. 15 gets the Budget Buy pick for heavier jobs. A roll of each will handle most marlinspike projects on a mid-size cruising boat.

FSE Robline Dyneema twine

Dyneema is stronger than polyester, so the 1-millimeter size printed on the spool would suggest that this Dyneema twine should be much stronger than other 1-millimeter twines. In fact, this is not 1 millimeter in diameter; it is 1 millimeter when flattened out on a spool, but has only the cross-sectional area of 0.4-millimeter twine. With a tensile strength of about 80 pounds, it is actually weaker than 1-millimeter polyester twine. It has a greater tendency to cut through polyester and nylon fibers, creating constructions weaker than those sewn with 0.4-millimeter polyester twine. Though it still sews well without wax, it lacks sufficient body to handle easily and is not good for end whippings; polyester serves as well with less effort.

On the other hand, Dyneema twine shows exceptional abrasion resistance, wearing five to 10 times longer than polyester twine in lab testing. Certainly, Dyneema twine is the best product for sewing Dyneema line and webbing, but we have reservations about using it on high-load applications with polyester and nylon. In prior testing (see PS, October 2014 online), we saw 25- to 40-percent weaker constructions with Dyneema because the Robline Dyneema was actually cutting through the rope or webbing.

Bottom line: While waxed polyester is the correct choice for sewing nylon and polyester materials, we gave Dyneema a Recommended rating for sewing high-modulus materials and where abrasion is a major concern.

Berkley Fireline

Many sailors use Dyneema fishing line as whipping twine, because it is more widely available. (It is often used in fishing as a bite leader.) Fishing line is braided, so the Berkley Fireline has a stiffer feel than the Robline material, although this doesn’t make any practical difference. The Berkley Fireline Dyneema fishing lines abrasion resistance was similar to that of the Robline Dyneema, and it sewed without difficulty.

Bottom line: If youve got some Dyneema fishing line in the tackle box, theres no reason not to use it. Its Recommended. Just be aware of Dyneema twines tendency to cut into polyester and nylon rope. Follow the same guidance as for the Robline Dyneema.

Marlow Whipping Twine

The Marlow waxed, laid-polyester twine is very similar to the Robline laid polyester twine, but is more readily available on small spools. It is sold in four sizes: Nos. 2, 4, 8, and 16; but these do not coincide exactly with the Robline sizes. The twist was a little less pronounced than Robline, resulting in fewer tangles when sewing canvas. Spool sizes vary.

Bottom line: Weve used Marlow twine for 25 years and know it to be a dependable product. Marlow No. 4 is Recommended for canvas repair; for heavier jobs, No. 16 is Recommended.

Conclusion

To put it simply, you really can’t go wrong with polyester twine. Use the largest size appropriate for the project, braided if available. The Robline No. 10 is our all-around Best Choice for general use, and the Robline No. 15 is the best deal for heavier jobs. If you like smaller spools, the Marlow No. 16 is a good choice for heavy projects, and Marlow No. 4 is Recommended for canvas repair. Use Dyneema twine only when sewing Dyneema line or a project where added chafe protection is sought specifically. The wear resistance of Dyneema twine is impressive, but its inelastic nature restricts its uses.

you don’t mention UV resistance ??