Bottom Paint Checkup 2014

Bottom paint? Again? Frankly, sometimes we feel that way, too. According to company lore, more than a few former Practical Sailor editors ran screaming for the exits after phrases like ablative copolymer and Irgarol began creeping into their dreams. As much as some like to poke fun at our bottom paint obsession, antifouling is a topic that deserves attention. Choosing the wrong paint can set a boat owner back $1,000 or more, but more importantly, antifouling is a fast-moving topic; paints available last spring are suddenly gone, renamed, or reformulated. This is particularly true for the newer eco-friendly paints.

Prop Paints Show Familiar Signs of Failure

Weve experimented with several different prop paints with varying degrees of success, although none of the results so far have been dazzling. Some of our testers have had better success with dedicated slick prop paints such as PropSpeed. In our testing, however, mostly in Chesapeake Bay, no prop paint had lived up to our increasingly faint hope that the paint repel growth as effectively as our hull paint.

The Ins and Outs of Choosing a Bottom Paint

When choosing a bottom paint, make sure it is compatible with your existing paint, or be prepared for whatever extra prep work might be required. Usually, all that is required is some light sanding and possibly, a primer coat, although in some cases, more aggressive sanding and surface prep is required.

Tefcite Coating Fails Static Panel Test at 1 Year

Our quest for new antifouling paints recently took us into the world of long-life spray-on coatings promoted in the commercial-shipping industry. While the spray-on, thermoplastic composite powder Tefcite may work well on a ship thats moving at 13 knots for most of its working life, it failed surprisingly fast in our static panel tests.

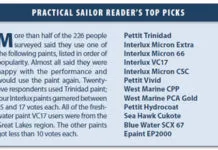

Favorite Bottom Paints by Region

Lately, readers have been asking us about which antifouling paints serve well for specific bodies of water (or type of water). So, in this article-our annual spring bottom paint report-we will try to answer these questions with some recent reader survey data and sales reports from the two biggest brands in the U.S. (Pettit Paints and Interlux Yacht Finishes). But before we get into the regional breakdowns, a quick recap on choosing bottom paint and our paint testing program is in order. If youre a longtime subscriber, feel free to skip down to the Current Testing section.

For Big Repairs, Try Bellwether Boatyards

A few years back, we profiled a number of excellent local boatyards (PS, June 2009) that help do-it-yourselfers thrive. Here, we profile yards at the opposite side of the spectrum-facilities that specialize in keel-to-masthead care for their customers.

Do-It-Yourself Nonskid Test Update

Its been 12 months since testers mounted the 12 nonskid test panels on the roof, subjecting them to south Floridas semi-tropical weather around the clock, without any cleaning. The test field included the big names in marine maintenance products-AkzoNobel (Interlux and Awlgrip), Pettit, West Marine, and Epifanes-as well as companies specializing in nonskid paint, Pachena (KiwiGrip) and Durabak, and three that make nonskid mats, SeaDek, Tiflex, and Soft Deck. With the service life of nonskid paints and mats ranging from three years to a decade or more, we didnt expect to see much change in the test panels, but there were a few surprises.

Get Longer Life Out of Your Nonskid

Revamping a nonskid deck is not a project most boat owners look forward to doing. Here are a few tips to help you get more mileage out of those arduous nonskid restorations.

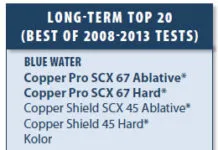

Which Bottom Paints Last the Longest?

Over the past five years, in our search for the best bottom paints, weve reported on three sets of bottom paint test panels that have been in salt water for two years or more. Most panel sets contained the same roster of 60 to 70 antifouling paints from Blue Water Paints, Epaint, Interlux, Pettit, Sea Hawk, and other makers. In the end, only seven antifouling paints proved capable of combatting barnacles after 24 months. We consider these to be the most reliable bottom paints available for the cruising sailor.

3M Masking Tape Matchup

Most sailors have discovered that when it comes to applying marine coatings, the type of masking tape used is as important as the type of paintbrush if you want clean edges. But what is the best tape to use for boat varnish projects, or bottom paint application? Testers compared eight of industry leader 3Ms general masking and specialty tapes to find out.