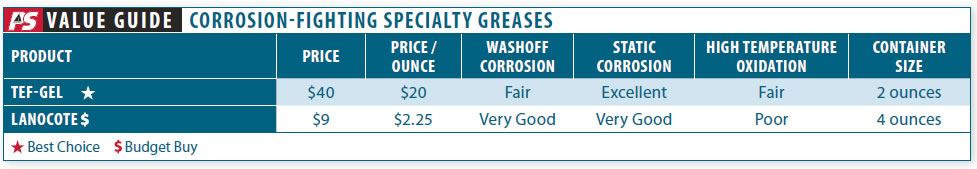

In this update of our review of greases (see PS February 2017) we compare Lanocote and Tef-Gel, greases that are used to prevent metal corrosion. Tef-Gel, from Ultra Safety Systems, is often prescribed to prevent stainless-steel fasteners from seizing in aluminum. Lanocote, made by Forespar, is commonly applied to prevent seizing in turnbuckles and other components that need lubrication.

As in our previous tests, we applied these products to five different metal coupons (copper, bronze, aluminum, and two grades of steel) and then tested them for corrosion protection, resistance to being washed off, and resistance to oxidation at high temperature.

This project should be framed as a comparison between examples from each of the two categories of greases-organic vs. synthetic. It is not a strict head-to-head test. Lanocote is derived from sheep lanoline, one of the worlds oldest greases, while polytetrafluoroethylene (PTFE, aka Teflon) is a 20th century synthetic. There is a range of similarly formulated products in either category that we expect would deliver comparable results. (Forespar makes its own synthetic product, Marelube TEF 45, that would be a better match for Tef-Gel in a true head-to-head.)

Lanocote

Whereas most greases are made from thickened lubricating oils, Lanocote is derived from a fat. It is not thickened, rather it is naturally nearly solid at room temperature. It sticks tenaciously to metals, and can even be applied under water. The result is impressive multi-metal protection. Our testers found it too viscous for applications requiring easy movement, such as winches and folding props. When exposed to high temperatures, it oxidizes quickly into a hard wax-like consistency.

Some sailors swear by it for Lanocote seacocks, but its most widespread use is for warding off corrosion on turnbuckles and preventing fasteners from seizing.

Bottom line: Organic greases offer an affordable route to corrosion protection for non-moving parts. Budget Buy.

Tef-Gel

Tef-Gels specialty is preventing stainless-steel fasteners from seizing in aluminum. As the name implies, it has some PTFE in it. Although it is not as thick as Lanocote, it is a very sticky, thick gel that doesn’t spread as evenly as an ordinary grease. Because it is generally used to lubricate fasteners, it comes with tiny brushes that work perfect for brushing the gel deep into the female threads.

Tef-Gel stood out as the only product that allowed the metal coupons to rotate in place even after they had been fully tightened down. If you are using this on larger (1/4-inch or larger) nut-and-bolt assemblies youll want to use a lock nut or lock washer to prevent the nut from loosening. Tef-Gel showed exceptional resistance to high temperatures, making it useful in all but the most extreme high-temperature applications (exhaust manifolds, for example). Its performance during the washout test was not as good as some other synthetic greases we tested in February 2016.

Bottom line: PTFE synthetics have rightfully earned high marks for their anti-seize protection. Best Buy.

Conclusion

If theres heat or movement involved synthetics excel. As for corrosion protection, both types do an excellent job. Other anti-seize products weve recommended in the past include Duralac (www.llewellyn-ryland.co.uk), ECK (www.eckcorrosion.com), and Loctite (www.loctite.com). We have placed some coupons protected by Lanocote and Tef-Gel into long-term testing and will report our findings.

A retired engineer who worked on subs told me that AquaShield grease beats all these products. They ran a salt water galvanic tab 6 months test on multiple products and AquaShield was the best to be used for underwater and dissimilar metals applications. Will be nice to get it tested by your team.

Will SuperLube, a PTFE based lube, work as well as Tef-Gel? Seems like an interesting test.