About this time of year, many of our readers will experience a gradual loss of engine power, maybe even a complete shut down. Theyll pull the filters and find them so clogged youd think the last fill-up was a spinach smoothie.

The bad news is that getting rid of that gunk will require a bit of an investment-if not in money, then time. The good news is with careful fuel management you can prevent this from happening again. If you have persistent fuel issues-gasoline or diesel-be sure to read the series of fuel-related articles found in our online archives. Just search fuel tank on our website.

Heres quick look at your options for resolving a contaminated tank as laid out by systems guru Steve DAntonio in a past issue of Practical Sailor:

For even a mildly contaminated fuel tank, you need to gain access to its inside. Organic contaminants include biological life forms both living and dead and mineral-based debris includes asphaltine, a tar-like, mineral-based substance that accumulates before it ever reaches your boats fuel tank. Additives may help prevent some contaminant build-up, however, no additive will remove years of accumulated organic- or mineral-based sediment or water-no matter what they claim. As for those miracle magnets that have reappeared on the market, weve seen no science to back up claims that magnets, or a specialized light source will stave off fuel contamination any better than common protective measures including filtration and regular treatment.

As several of our tests have demonstrated, it is possible to limit contamination (and tank corrosion) with the use of additives. A biocide like Biobor JF can help to control or limit biological growth, and as we found in our testing, this can be supplemented with an additive like Startron to fight corrosion. (See Diesel Additives, PS August 2013, and Diesel Biocides Take on Contaminated Boat Fuel, PS July 2009.)

Keep in mind that every time you shock or treat the tank, the bodies of what you kill will accumulate in the tank. No additive will dissolve their skeletons, which are abrasive and harmful to your engines fuel system. And too much of a good thing can be harmful: Some biocides, if overused, can be corrosive and damage your metallic tank or other fuel system components.

The best way to stem biological growth is to keep water out of the tank with a good tank design that allows access for cleaning and facilitates elimination of water (see Diesel Fuel Tank Replacement, May 2007).

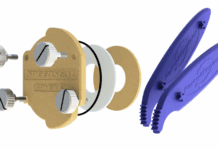

If you want to be certain that your tank is clean, the best and only sure way to do it is to get inside the tank. Its not as difficult as it sounds: Access plate kits are available. One, manufactured by Sea Built Inc., www.seabuilt.com, comes in several sizes; these can be installed on the tank top or side by a skilled do-it-yourselfer or your favorite boatyard. Once the inside is accessible, cleanup can vary from light duty swabbing with a lint-free rag (never use shedding paper-based products), to the heavy-duty, requiring mechanical abrasion with paint scrapers, gasket removers, brushes, and solvent. (Note: Access plates wont work with plastic tanks.)

How often youll have to do this chore depends on the quality of fuel you take aboard. Poor-quality fuel will increase the frequency of this event, while careful fuel dock discretion or funnel filtering may mean youll only be seeing the inside of your tank every four years-a familiar interval for dealing with built up detritus and debris in the U.S.