Photos Courtesy of Drew Frye and Big Orange and Vetus

304

While a boat’s sailing performance may be of primary importance to the skipper, you can bet that the boat’s livability is as important to the rest of the crew. Livability suffers when each flush of the head becomes public knowledge within moments, and a boat that is not livable won’t be a part of your family for long. Thus, from a certain point of view, a fresh holding tank vent may be one of the most important performance factor to the cruising sailor.

On one of Practical Sailor’s test boats, a PDQ 32 catamaran, the otherwise meticulous builder made an unforgivable blunder: The holding tank vent is just upwind of the main saloon’s air intake, and all emissions go through the cabin. We tried every common chemical treatment; none was dependably effective. We tried a larger holding tank vent, eventually increasing the vent to a 1-inch diameter, less than 30 inches long, with less than 18 inches of rise. No luck. We installed a home-built vent filter. Finally, success.

This Practical Sailor test built upon our learning process, and to be certain no rock was left unturned, we set up six 5-gallon “holding tanks” to test all of our theories. (The tester’s wife/first mate wasn’t too keen on the testing, but she was happy with the result.)

Photos by Drew Frye and courtesy of Dometic

259

Odor Control

When sanitary wastes are allowed to biodegrade in a closed tank, particularly with poor mixing and inadequate oxygen, anaerobic bacteria dominate. Instead of oxidizing the waste completely, they go only part way, producing some extremely malodorous products in the process; organic acids, assorted mercaptans, and hydrogen sulfide gas are chief among these. Detectable and unpleasant at sub-part per million levels, they can make a boat unlivable unless they are eliminated or contained.

The problem isn’t unique to boating; controlling mercaptan and other sulfide odors from chemical plants and wastewater treatment plants has been big business ever since neighbors realized they could complain about it, and the environmental movement provided the lever to force action. Some solutions—caustic scrubbing, incineration, and catalytic oxidation—simply aren’t practical on a boat. Additionally, they are often odor specific: Caustic scrubbing is effective in removing acid gases such as hydrogen sulfide and CO2 (a useful combination in spacecraft and submarines), but it will miss many other odors, and iron-ore fines react with and absorb sulfide but miss everything else. Perfumes are a patch at best. Formaldehyde—a common ingredient in old-style disinfecting treatments—can stop biological activity, but there is still chemical breakdown, plus it stinks and is listed by the EPA as a suspected human carcinogen.

Maintaining adequate oxygen in the holding tank promotes the growth of aerobic bacteria and is the primary tool of the wastewater industry; aerobic bacteria don’t produce sulfides, organic acids, or mercaptans, and they can consume those that are present. Chemical additives and selected bacteria or concentrated enzyme products are also effective, and are used in both large wastewater treatment plants and boat holding tanks. Carbon filters are often fitted to chemical process vents and are used to eliminate waste odors in applications ranging from the space shuttle to household bathroom fans, and have more recently been applied to marine holding tanks. These filters are simple, dependable, and absorb a wide variety of odors. Filters also require thoughtful installation and replacement when expended.

Odor is a complex issue. A great deal of money has been spent by chemical and marine industries on finding solutions, and we can’t tackle it all at once. We’re going to break this into pieces. Practical Sailor is currently investigating vent filters, improved ventilation, and treatment chemicals using a set of identical holding tanks. This article will focus on vent filters and holding tank ventilation. Our report on holding tank treatments was published in the February 2012 issue.

Another source of odor is permeation of the hoses connecting the head to the tank and discharge; many hoses begin to pass odor right through the side after prolonged exposure. We are testing this, too. The vent filter and hose permeation studies are long-term and will be presented in installments, as conclusive data becomes available.

Photos by Drew Frye and courtesy of Dometic

403

ASTM Testing

Standard ASTM methods for testing the capacity of carbon in vent filters to absorb odors call for drafting a mixture of hydrogen sulfide and carbon disulfide through a fixed-size bed. This test was developed to compare carbon types used for odor control applications in sewage treatment plants and is appropriate for that purpose. However, the test is not intended to determine whether a vent filter is effective on a marine holding tank or how long it might last in real-world onboard conditions, where thermal breathing is both in and out, and there are long periods of inactivity. (ASTM tests are designed to be fast, not to mirror real-world use.) Carbon tends to self-regenerate in these applications, much like the carbon canister in your car, and useful life expectancies can be quite long.

The primary interaction of carbon with organic vapors is surface absorption, as the ASTM standard tests explore. However, carbon is a complex surface and presents very complex behaviors. In the presence of fresh air, we have catalytic removal of sulfur by this simplified mechanism: 3O2 + 2H2S → (SO4)-2 + S + 2H2O.

While this reaction eventually fouls the carbon, it does extend its life many times over. The carbon bed must be sufficient in size, as this is a slow reaction in most carbons, and oxygen is only available in small amounts, provided by thermal breathing of the tank, inflow during pump outs, and slow bi-directional flow in the vent hose. The oxygen requirement is easily met, however, as it is much less than that required to support aerobic tank conditions. The standard ASTM methods are not ideal for estimating carbon life when catalytic reactions are present, because the method substitutes nitrogen for air, eliminating oxygen from the process.

Additionally, the carbon does not need to remove sulfide—or any other odor, for that matter—on a continuous flow basis to attain odor control; it need only temporarily absorb and delay the peak load for a few minutes while the toilet is being flushed. If the filter absorbs the sulfide load only temporarily and bleeds it off over a period of hours, noticeable odors are eliminated. Continuous-flow laboratory testing does not measure this “time-delay” influence on surges. In industrial practice, it is not unusual to see carbon beds that have become saturated on a continuous-flow basis within weeks continue to serve very well as peak absorbers for many years.

There are limits. Eventually, the carbon becomes fouled by non-volatile reaction products and damaged by acid build up. Additionally, the bed must be large enough for these slower processes to function.

What We Tested

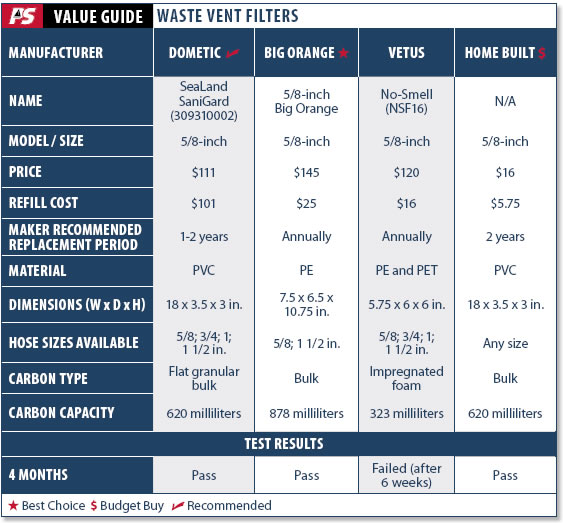

Practical Sailor rounded up three popular, commercial waste vents and a home-built system to evaluate. Each test unit contains activated carbon and is intended to be installed in a 5/8-inch diameter vent hose. From marine plumbing manufacturer Dometic, we tested the SeaLand SaniGard vent filter. We also tested the 5/8-inch filter from Canadian manufacturer Big Orange and the No-smell NSF16 from Vetus, a marine manufacturer based in Maryland.

All makers suggest replacing the vent filter media annually, but user field experience indicates that the service life of a vent filter can vary greatly and averages about two years. According to Big Orange, the company advises users to replace the carbon every year, but achieving a service life of up to three years is not uncommon.

Plan to replace filter media every year or two, but be sure to inspect the vents more frequently to ensure there are no system clogs. (See “Avoid Plugging with Proper Installation.”)The vents will last longer if they are protected from salt water and holding tank overflow.

Dometic

Fabricated from 12 inches of 2-inch PVC pipe and custom end fittings, the SeaLand SaniGard filter is a simple but effective holder for bulk carbon, which does the work.

The company has studied many carbon types in the lab and claims to use a type that’s far more effective than that used in competing filters. Indeed, industry practice confirms that certain types of carbon are better suited to odor removal than others, and the Dometic test data convinced us that the company has done its homework in this field.

The mounting hardware is minimal but functional.

To refill the SaniGard, users must replace the entire cartridge, which costs about 90 percent of the price of a new unit (based on manufacturer’s suggested retail price).

Bottom line: The SeaLand SaniGard is expensive and not a bargain to refill, but it uses high-quality carbon. It gets PS’s Recommendation.

Photos by Drew Frye and courtesy of Dometic

173

Vetus

The Vetus No-smell NSF16 filter is unique in this group because it uses a carbon-impregnated filter media instead of bulk carbon. The package and the mounting are sharp, and the media are easily replaced, but the performance was disappointing.

The media contains far less carbon per unit volume than other test products, and the volume of the unit is small. The instructions suggest that this unit was originally designed for fuel vent applications, and it may work better for that.

On a side note, we suggest lubricating the cover with silicone grease, if you ever expect to get it off.

Bottom line: In our opinion, rapid failure removes this filter from serious consideration.

156

Big Orange

As the name implies, the Big Orange filter was the largest of the test field. Refills are either bulk carbon from the manufacturer ($25), or you can find your own local bulk carbon source. Changing the carbon is a simple matter of pulling out a drawer, dumping, and refilling; it couldn’t be easier.

It is the only unit on the market that includes a vacuum break valve in the design, which is essential to protect the holding tank in the event of filter plugging.

The only shortcoming testers noted was that it was designed to mount on a horizontal edge—the top of the holding tank—and we’ve found that it is better mounted high on a bulkhead, which the manual suggests; a simple cleat or bracket will solve this.

Bottom line: Top features and lower long-term operating cost make the Big Orange a good choice despite its higher initial price. It’s the PS Best Choice.

Home-built Filter

Similar in size to some commercial vent filters, our DIY vent filter is made from 12 inches of 2-inch PVC pipe. Testers tapped NPT-to-garden hose adapters into PVC end caps, but this transition could as easily be accomplished with a collection of bushings available at the local hardware store. The filter used in side-by-side testing was not designed for refill; however, a very similar home-built test filter was installed on a test boat, and that unit is refillable. To accomplish this, one end cap is not glued on but rather held in place with a 2-inch, no-hub connector—a simple hose with 2 clamps available in any hardware store. It was mounted in a wooden saddle, but two 2-inch PVC conduit clamps would make a simple, durable, and inexpensive bracket.

Bottom line: If you’re at all handy, there’s no reason you can’t fabricate a durable and economical filter with common tools. This option is the Budget Buy choice.

318

Conclusions

If the holding tank vent on your boat is in a particularly sensitive location, vent filters offer complete odor control at a cost competitive with chemical treatment options (PS, February 2012). As the only vent filter to fail in our test was the carbon-impregnated Vetus, we can only recommend using bulk carbon filters that are refillable; these offer the best long-tern economy.

How long will carbon last? This is a very complex question, not easily resolved with lab test methods or even extended field testing. Simple sulfide generation, breathing, and absorption calculations suggest that the carbon should be saturated in weeks or months, but field testers report life times of up to five years. We will continue our exposure testing until failure, both in test tanks and on-board our test boat, and report back as we learn more.

All the vent filters tested seemed well-built and durable enough to last several seasons in a protected location. All survived a season outdoors and rough handling, but proper installation is a must. A high mounting location and a vacuum break are required, and pressure relief and overflow by-pass plumbing are recommended.

If your vent is in a sensitive location and chemical treatments have not worked for you, give a vent filter a try. (But remember to follow our installation tips.) The result obtained with a vent filter is different from that obtained through ventilation and treatment chemical options. Filters offer perfect odor control with little to no operator attention. Chemical treatments offer more variable control and require regular treatment—skip a dose or leave a partially full holding tank for a few weeks, and things can turn unpleasant. Improved ventilation alone offers substantial improvement and may be enough in most cases, but not complete control for the most sensitive vent placements. Freshwater-flushed systems will have less odor.

Testing will continue for at least one year to accurately project operating life. A minimum two-year life expectancy has been reported by many users, with up to five years achievable with light use and good installation. Because of the combined absorptive and catalytic mechanism, we recommend that boaters who live aboard or have larger holding tanks (more than 40 gallons) use the largest unit (Big Orange) or custom-fabricate one in order to ensure maximum service life.

See the February issue for the initial results of the our chemical tank treatments test, and stay tuned for our report on waste hoses in the April issue.