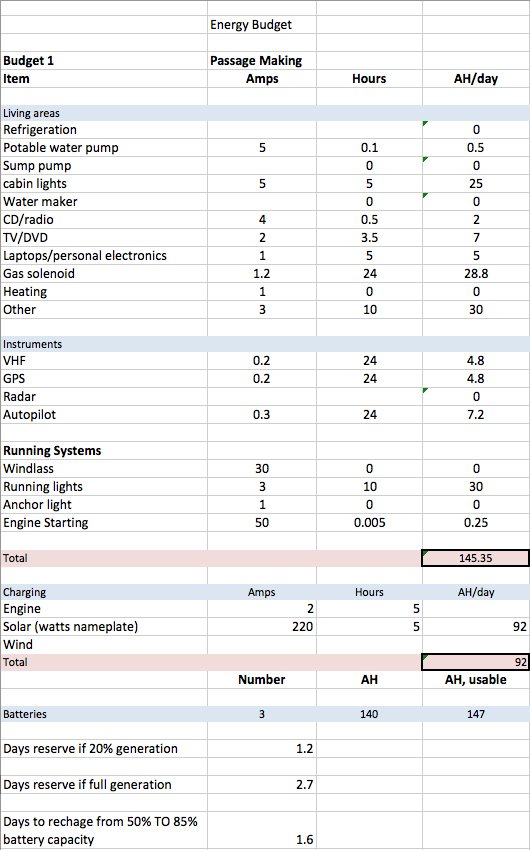

The starting point for a successful solar panel installation is quantifying your requirements. We present here a simple analysis based on the test boat used for our recent report on choosing and installing a solar panel. Some values are from experience, and others are accepted rules of thumb. For more details on choosing and installing a solar panel, see the March 2018 issue of Practical Sailor online.

Energy Balance

Look up the current draw of each piece of equipment (confirm with panel ammeter if available) and estimate the number of hours operated. Record the number and capacity of your batteries, recognizing that you cannot draw below 50% charge without shortening their life, and that you will seldom charge past 85% while away from the dock-as a result, only 35% of nameplate capacity is really useable. Finally, total your charging sources, including engine, wind, and solar. For solar, take the rated wattage x 5 hours/12 = amp-hours while on passage and wattage x 7 hours/12 = amp-hours while at anchor (sails do not shade and the boom can be rigged out to the side). This is far below the rated capacity-sailors in the tropics will do better, and sailors farther north or sailing in the winter more poorly-but this is an accepted starting point.

Estimating Panel Output

| Full Sun-Panel square to the sun | 100% |

| Full Sun-Panel at 45 angle to sun | 71% |

| Light overcast | 20-70% |

| Heavy overcast | 10-20 % |

How many days can you manage with poor generation? Are you willing to economize during a long cloudy stretch? Will you recharge at a marina or by running the engine periodically? Long-term cruisers appreciate an abundance of power, while the occasional cruisers may be satisfied with less.

Saving Power

Every AH (amp-hour) consumed has a real cost in weight, panels, and dollars. If you can reduce consumption by 50 AH/day you will save a battery (the useable capacity), a 120 watt panel, and perhaps a mounting arch. The cost savings might be $500 and 150 pounds for just a few bulbs.

- Lighting. Switch from incandescent to LED and fluorescent lighting, starting with the lights you use most. We use LEDs and fluorescent for the anchor, salon, and cockpit lights, but since we seldom run at night, we left the running and steaming lights alone. Likewise, the deck light and many task lights remain halogen or incandescent; they are not used enough to matter.

- Go to bed at night and get up with the sun. Big savings in juice and more time to play.

- The gas solenoid is a big user for us; it runs the propane fridge and cabin heater, so it is on for long hours, but we can turn it off at night or go without refrigeration now and then.

- Fans. Run them on low speed and watch the hours. A wind scoop doesn’t use power.

- Instruments. Do you actually need GPS and other instruments full-time on passage? Twenty years ago they didn’t even exist. Balance the sails to minimize the load on the autopilot.

If you’re not sure if it’s time to upgrade or replace your solar panels, the upcoming June 2023 issue offers detailed guidance on evaluating old solar panels and house batteries. If you are upgrading your boat’s electrical system, adding new accessories, or just replacing some wires, our recently updated six-volume ebook Marine Electrical Systems covers everything you need to know about electrical systems–including Batteries, System Installation (including rewiring and lightning protection), Panels, Monitors, Charging, Alternative Energy, and AC Systems.

Power Usage Table

Drew Frye is a frequent contributor to Practical Sailor. He blogs at www.saildelmarva.blogspot.com

Good subject; article can not be understood by most people.

What people need to know is: I have a x feet sailboat; my boat sits idle y days/week, I live in z area; how many watts will I need most of the time?

What people need to know is; do I have enough places to put the panels, are there panels designed to work well vertically, are flexible panels practical?, etc.

Thanks

There really isn’t any way to get a realistic daily usage estimate without an amp-hour meter. Do you actually know how many hours per day the fridge compressor runs? They cost a couple hundred and take a couple hours to install.

On my boat, it’s the fridge that is the energy hog. Long ago, I replaced almost all lights (cabin, navigation, and anchor) with LEDs. Cut energy use significantly and worth the money. Newer electronics also have lower draw than very old units. Radars now work at a tenth the prior draw.

Can any readers comment on solar panel output for various mount locations? Bimini, dodger, rotating on stanchions, cabin top What’s best? What’s acceptable?

BTW Boats with a head and galley qualify as second homes and thus are eligible for federal credits for solar panels and batteries bigger than 250 amp-hours. 30% off

After communicating with someone cruising in the Pacific I followed his advice…”Put up as much solar you have room for and you can afford.” With that advice I installed 4x140W (560W) Kyocera panels; 2x140W over the dodger and 2x140W on a new stern arch on my Tayana Vancouver 42. The panels are permanently fixed and I never worry about adjusting them for the best angle. On my roundtrip to Hawaii I never had to start the diesel engine to charge the batteries and I don’t have a genset. I did use the Pacific Cup 2012 Sample Energy Budget as a template and modified it for determining my energy use and highly recommend it. I strongly second the comments about being reasonable in your use of electrical power as it is the easiest and most cost-effective way to manage that requirement…take a very hard look at everything that uses electrical power; do you really need it or use it as much as you do?

I don’t understand the reference to just LA/Flood batteries…

I havev all LiFePo4 both main bank and 12v house and never have any power issues…

I simply maxed out as much as physically possible on my narrow beam 40ft sloop both PV and storage…

A couple items i dont understand. The ‘charging chart’ above has engine charging at 2 amps. This seems very low. Most alternators output in excess of 50 amps. Plus the chart has 2 amps for 5 hrs with a total AH of blank. Also dont understand the ‘solar charging row’. The number just dont jive.

The 2 amps is easy; the example boat had two 9.9 hp outboards that charge 1 amp each. Yes, 2 Amps x 5 hours should have been 10 Ah. Of course, many days the engine does not run.

The refrigeration on the boat in the example was propane, thus no usage.

Additionally, it should be obvious that not all of the items will happen every day. Passage making and at-anchor are different.

Every boat is different. The idea is that by estimating usage, generation, and inventory (batteries) you can better understand your system.