Insulation is a greater energy-saving expedient; if our heater or air conditioner is undersized, fixing drafts, shading or insulating windows, and insulating non-cored laminate are all ways to reduce the thermal load. For boaters, however, that is only half of the equation.

In Florida, air conditioning ducts can fill with condensate and breed a horrible mildew soup. In Maryland, a cold drip from a window can ruin a deep winters slumber. In Winter Sailing Tips for Die-Hards, (Practical Sailor, December 2016) we touched on insulating windows, plugging drafts, and humidity control. In Insulating Against the Cold and Damp, (Practical Sailor, January 2018) we compare various insulating materials and their effectiveness in reducing humidity by keeping boats (or any interior space, for that matter) dry and comfortable. Stay tuned for that article in the next few weeks.

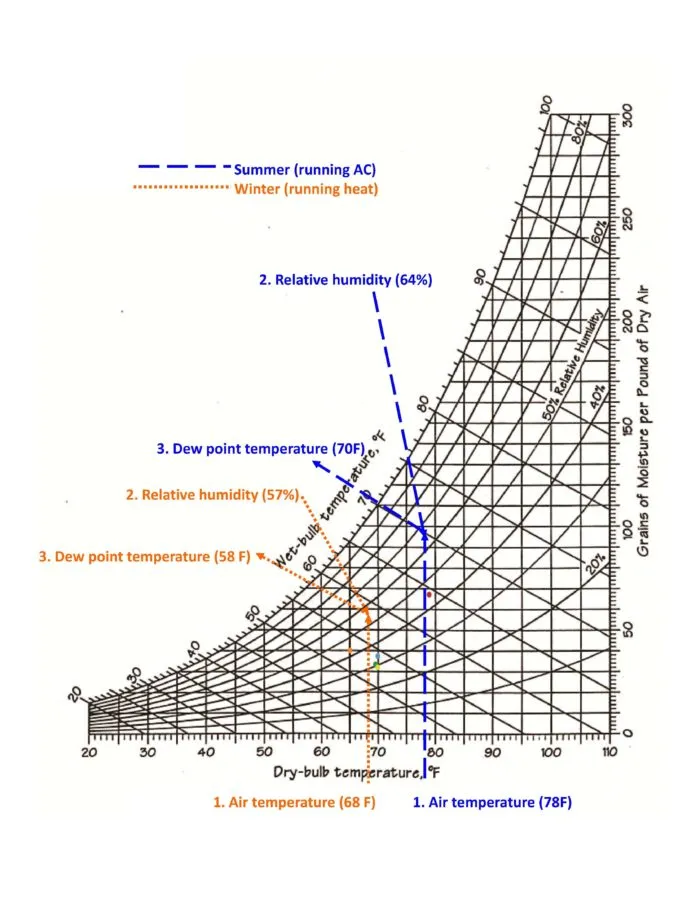

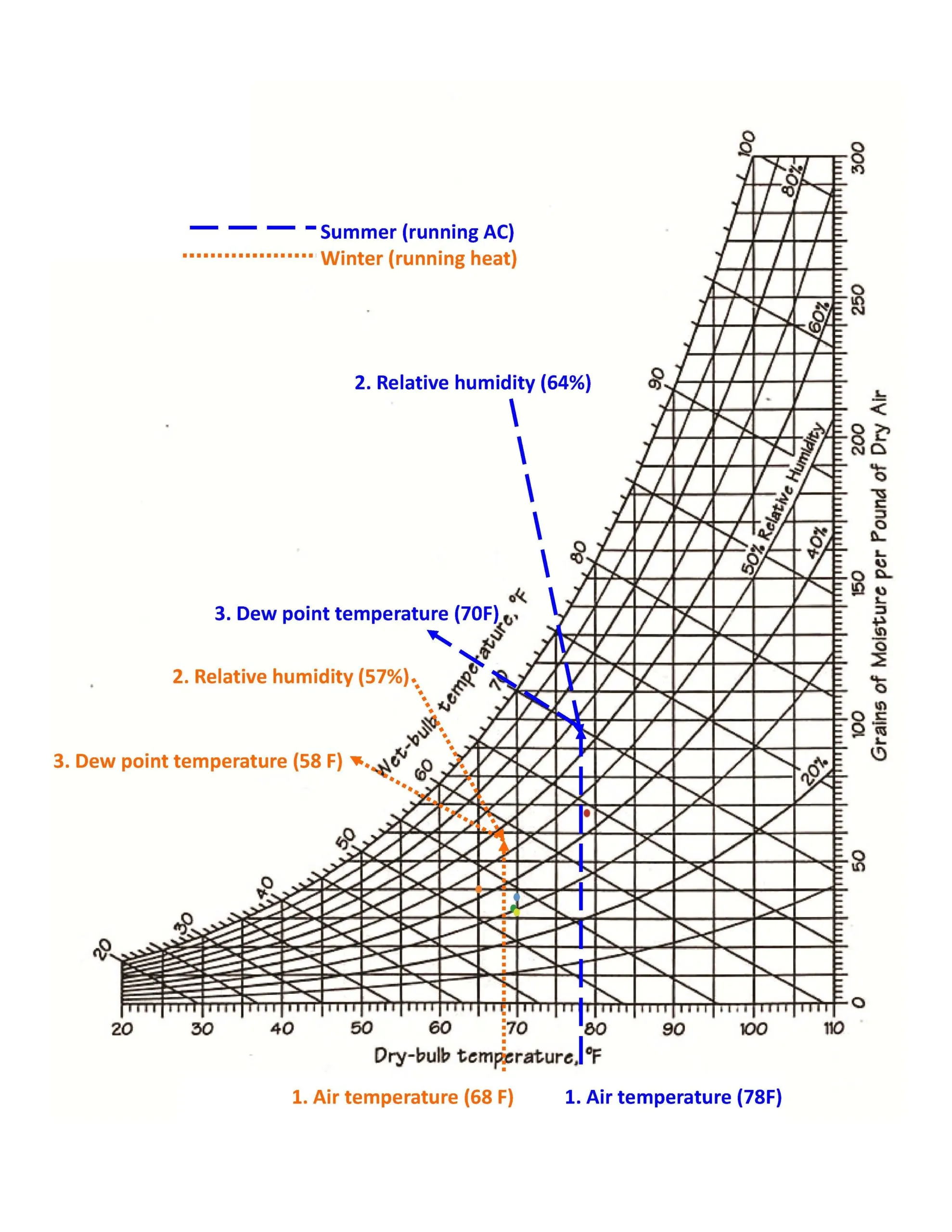

Whether a surface sweats-a cold window in the winter or AC ducts in the summer-depends on if the surface is below the dew point. The dew point varies with both temperature and relative humidity, and one of the easiest ways to visualize this relationship is with a psychrometric chart. The adjacent psychrometric chart illustrates the worst case winter condition (68 F in the cabin, 55 percent relative humidity, 57 F dewpoint) and summer condition (78 F in the cabin, 64 percent relative humidity, 70 F dew point) on the test boat. In theory, any surface below the dew point will sweat, and this was very close to our experience; any surface that was below the dew point for significant time periods got wet and mildew bloomed. Needless to say we corrected these problems with a combination of insulation and controlled ventilation.

Drew Frye

Insulation must be sealed. If the outside or duct temperature is below the dew point, there will always be a location within the material that is at the dew point. Moisture will be drawn to that area. There are only two ways to avoid condensation within the insulation. In the case of fiberglass insulated AC ducts, the insulation has an air-tight jacket, and the jacket is sealed with duct tape and captured under clamps at each cut end. Alternatively, a non-absorptive insulation such as closed cell foam can be used, but it must be tightly bonded-not just taped-to the surface so that air cannot get under it.

Perhaps the most common failure to understand this is demonstrated by mildewed vinyl-covered foam ceiling liners. Installed over a non-cored hull, these are virtually guaranteed to sweat, even if deck fitting leaks don’t get them first. All of the benefits of insulation can be overwhelmed by the downside of mildew growth unless insulation is very carefully installed.

If you are already dealing with a mold or mildew problem, our blog post Preventing Mildew in Marine Fabrics, offers tips on cleaning mold and mildew stains and preventing the from coming back.

Curiously, the best way to prevent condensation in uninsulated spaces during winter is to let them go cold and restrict ventilation. The more warm dry air you pump into them, in an effort to dry them, the more water you have made available to condense. Instead, only ventilate these spaces on the coldest, driest of days, when you can leave the boat (people add moisture) and let the heater and dehumidifier do their work. We have areas in the test boat that are well below the dew point (bilges), but they stay dry so long as we don’t try to air them out.

Another common humidity problem area on sailboats? Sails are prone to mold and mildew too. Practical Sailor‘s “Dealing with Dirty Sails,” offers some help with this issue too.

To download a PDF version of Practical Sailor‘s psychrometric chart, click here.

See the January 2018 issue of Practical Sailor for our report on inexpensive insulation products that can help reduce humidity on your boat throughout the year, especially in winter and spring.