Plugged Through Hull Solution

My summer cruise took me up to the Discovery Islands just north of Desolation Sound off the coast of British Columbia with sailing buddy...

Considering Fiber-Reinforced Composites for Sheathing

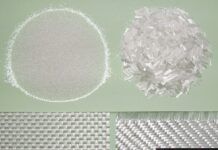

As we explore material legacies and evolution with a regenerative lens for our Wharram Narai Mk IV build, the focus now shifts to sheathing...

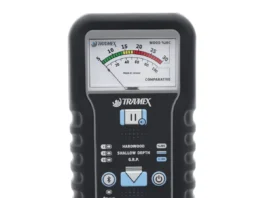

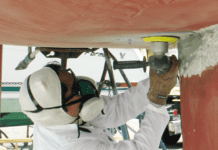

DIY Fairing and Filling

Epoxy deserves its wonder resin status as a highly adhesive, water-resistant laminating resin. It is the secret sauce behind a shelf full of fillers, glues, and fairing compounds.

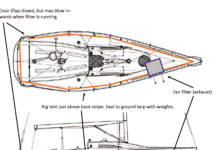

Making Your Own Workshop Filter

It all started when I needed to make a number of large cuts inside the house and outside of the confines of my shop....

Shock Cord Hardware for Sailors

Every rope we have on board has its quirks when you’re trying to form a knot that won’t slip or come untied.

Dyneema is a...

Glues and Resins: Can Boatbuilding Be Regenerative?

The use of glues and resins is indispensable in modern wooden and plywood boat construction. Ahead of self-building a 41-ft. Wharram Designs Narai Mk...

What Are the Best Options in Hose Clamps and Barbs?

In “Stainless Steel Hose Clamps,” February 2016, we reviewed hose clamps by testing corrosion resistance and clamping security. Not a lot has changed; cheap...

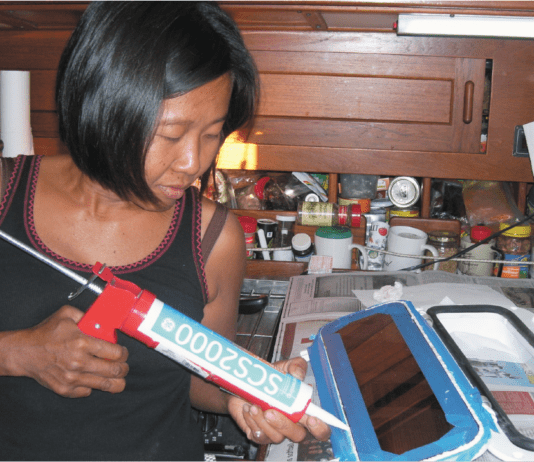

Refurbishing the Inflatable Dinghy

Inflatable tenders have become the family car for many cruisers. They haul groceries, take us to snorkeling spots, shuttle guests, haul out second anchors,...

The Best Gloves for the Boatyard

We choose our sailing gloves and deck shoes with great care, because they are our interface with the boat. The same goes for work...

A Brief Modern History of Fiberglass

Fiberglass, also known as glass-reinforced plastic (GRP), has been an integral material in modern engineering and design, especially within the marine industry. Its lightweight,...