Choosing a marine caulk for use above the waterline comes down to which product offers the best resistance to weathering, dirt, mildew, and ability to maintain a good bond when flexed. The lowest performer was Boat Life Caulk, which did not adhere well to any test surface.

This test was a follow up to a test of how caulks differed in shear strength reported in “Marine Sealant Adhesion Tests,.” For this update we found a significant difference in dirt attraction, with rougher surfaces attracting more dirt. However, even the dirtiest caulks came clean during a normal washing. Sudbury Elastomeric Sealant proved to be the best product for bonding polyethylene.

In our reporting 3M 4200 Fast Cure showed good flexibility, adhesion, and superior weather resistance, but inconsistent bonding to aluminum and plastics during shear testing. 3M 4000 UV is comparable to Loctite Marine and recommended for applications exposed to weathering. (3M 5200 is not recommended for most DIY jobs due to its stiffness and lack of flexibility and difficult-to-remove adhesion.)

Sika 291 performed similarly to 3M 4200 Fast Cure but with more consistent bonding and a greater tendency to attract dirt. Sudbury Elastomeric Sealant is flexible, weather resistant, and consistent in bonding, making it a good candidate for removable hardware and bonding polyethylene.

Loctite PL S-40 is a budget buy with flexibility, good strength and adhesion, and similar weather resistance to more expensive products. BoatLife Life Calk failed to bond effectively and lacked flexibility, while BoatLife Life Seal performed acceptably but contained silicone. The best choice depends on priorities, with some products delivering nearly identical performance. Silicone and butyl rubber were not included in the review but have their special purposes for specific projects.

HOW WE TESTED

The primary focus of our ongoing caulk test is to evaluate above-the-waterline bond strength with various materials. When we were making up shear-strength samples used in Part 1, we bonded 20 fiberglass samples (1.25-inch by 6-inch) and placed them on the roof to endure nature for a year, and now we’ve learned a bit more and the data from our 2016 report-republished here with the new data-reveals how caulks with similar formulas and stated purposes can perform differently with the same substrate.

OBSERVATIONS

The lowest performer was Boat Life Caulk. While it has enthusiasts as a bedding compound, it did not adhere well to any test surface, peeling away cleanly.

The second surprise was the significant difference in dirt attraction. At first glance, we mistook the soil on some of our samples for mildew growth, but when we wiped the samples with a cloth and plain water, they all came clean. If there was mildew, it was rooted only in the accumulated dirt. Nevertheless, testers noted an obvious difference in the surface texture-ranging from that of a dirt-repellant silicone finish (Boat Life Seal) to that of a static cling mat (Sika 291)-with the rougher surfaces attracting more dirt.

We know that organic matter can foster mildew growth, or eventually stain, but at this point, even the dirtiest caulks came clean during normal washing. Even if some porosity or staining were to occur, the harm would likely be superficial since the caulks are so thickly applied. Paints, on the other hand, are much more vulnerable to permanent staining or porosity at the surface.

As an additional long-term test, we rebonded sections of a watertight bulkhead in a polyethylene (PE) kayak. The factory silicone caulk and several attempts at re-sealing using polyurethane sealants from 3M and Sika products failed within months. Even though the bulkhead is flexible (polyethylene foam), the sealants tore loose when the bottom flexed, as it did often during normal use. Two years ago, we resealed it with Sudbury Elastomeric Sealant, the best product for bonding polyethylene in Practical Sailor testing. This adhesive sealant-which also works well with Starboard-is still holding tight, with no hint of separation.

3M 5200

Intended as a permanent bonding adhesive, 5200s stiffness worked against it in the flexibility test. Although this polyurethane (PU) sealant was thinly applied compared to other products we tested, it took more than twice as much force to flex the samples. There was slight necking (a thin spot was created) during the flex test, though the necking did not seem to progress during the year.

Bottom line: 3M 5200s long cure and fiberglass-to-fiberglass adhesion works for builders, but for most DIY jobs there are faster-curing sealants with better flexibility and adhesion.

3M 4200 Fast Cure

Good flexibility, good adhesion, and superior weather resistance gave us a lot to like about this product. However, inconsistent bonding to aluminum and plastics during shear testing keeps it out of the top tier for adhesion.

Bottom line: Recommended for sealing fiberglass.

3M 4000 UV

After showing initially good performance, the 3M 4000 UV failed completely at about the five year mark in 2021. The product reverted to goo, potentially creating a potential mess for anyone who might on this caulk. We will be doing a follow up on the new formula that replaced it.

Bottom line: This is an extremely disappointing result, surprising from one of the leaders in this field. We will do an update on the new formula as soon as the new test results are available.

Sika 291

This 291s performance is similar to 3M 4200 Fast Cure, but with more consistent bonding and a greater tendency to attract dirt. Testers were impressed by Sika 291s reliable bonding ability.

Bottom line: Our Best Choice PU for a flexible and a reliable bond (except PE) for joints above the waterline. Its strong bond offsets its tendency to get dirty.

Sudbury Elastomeric Sealant

Flexible, weather-resistant, and consistent in bonding, Sudburys Elastometric Sealant does not bond as strongly as other sealants in the line-up, making it a good candidate for hardware that needs to be removable. We liked that the sealant always failed in shear before the bond failed. It is also the best sealant for bonding to polyethylene. It had some yellowing after two years, making this less desirable for exposed joints.

Bottom line: Recommended for general sealing and bedding, this is Recommended for bedding and bonding polyethylene.

Loctite PL S-40

A hardware store bargain, the S-40 is fighting out of its weight class, competing with products that are four times more expensive. And yet it delivered the same flexibility, good strength and adhesion, and similar weather resistance to the best in the field. It does have a greater tendency to yellow and attract dirt. We recently had polyethylene to polyethylene bond fail after 16 years underwater and multiple freeze cycles.

Bottom line: Our Budget Buy and a good option anywhere a large volume of caulk is needed above the waterline for unexposed joints. It is also a great product for use around the house.

Loctite PL Marine

This polyether, like 3M 4000 UV, delivered consistent bonding and weather resistance at a slightly lower price.

Bottom Line: Our best polyether at this stage of the test, Loctite Marine suffered adhesion and necking issues in followup tests.

BoatLife Life Calk

This sealant failed to bond effectively in our shear testing, and it failed the flexibility testing, debonding completely the first time the samples were bent. While you may like a sealant that is easy to remove, we think bond failure is never acceptable.

Bottom Line: This was the worst-performing adhesive in our test.

BoatLife life Seal

With better bonding and flexibility than Boat Life Calk, this polysulfide performed acceptably. However, unlike other products in our test, it does contain some silicone, which can affect subsequent bonding without treatment (see PS Tests Adhesive Removers, PS January 2017 online). The silicone gave it a smooth finish that resisted well any dirt or staining.

Bottom Line: Recommended as a bedding compound for mechanically fastened joints.

CONCLUSION

Although some products stood out for certain uses, we chose not to declare a single best, since three of the products are delivering nearly identical performance. The best choice often comes down to priorities. Do you want something tenacious, or are flexibility and ease of removal more important? Sometimes the answer isn’t obvious until it is too late and you discover the bond is failing or the bond is too strong when you need to take it apart. We also skipped silicone and butyl rubber in this review-these formulas have their special purposes, and should not be ruled out of hatch repairs and other projects that are better suited for these materials.

While a year was enough to reinforce our initial impressions, were going to leave the samples to weather for a few more years, flexing them every two months and see who fails next.

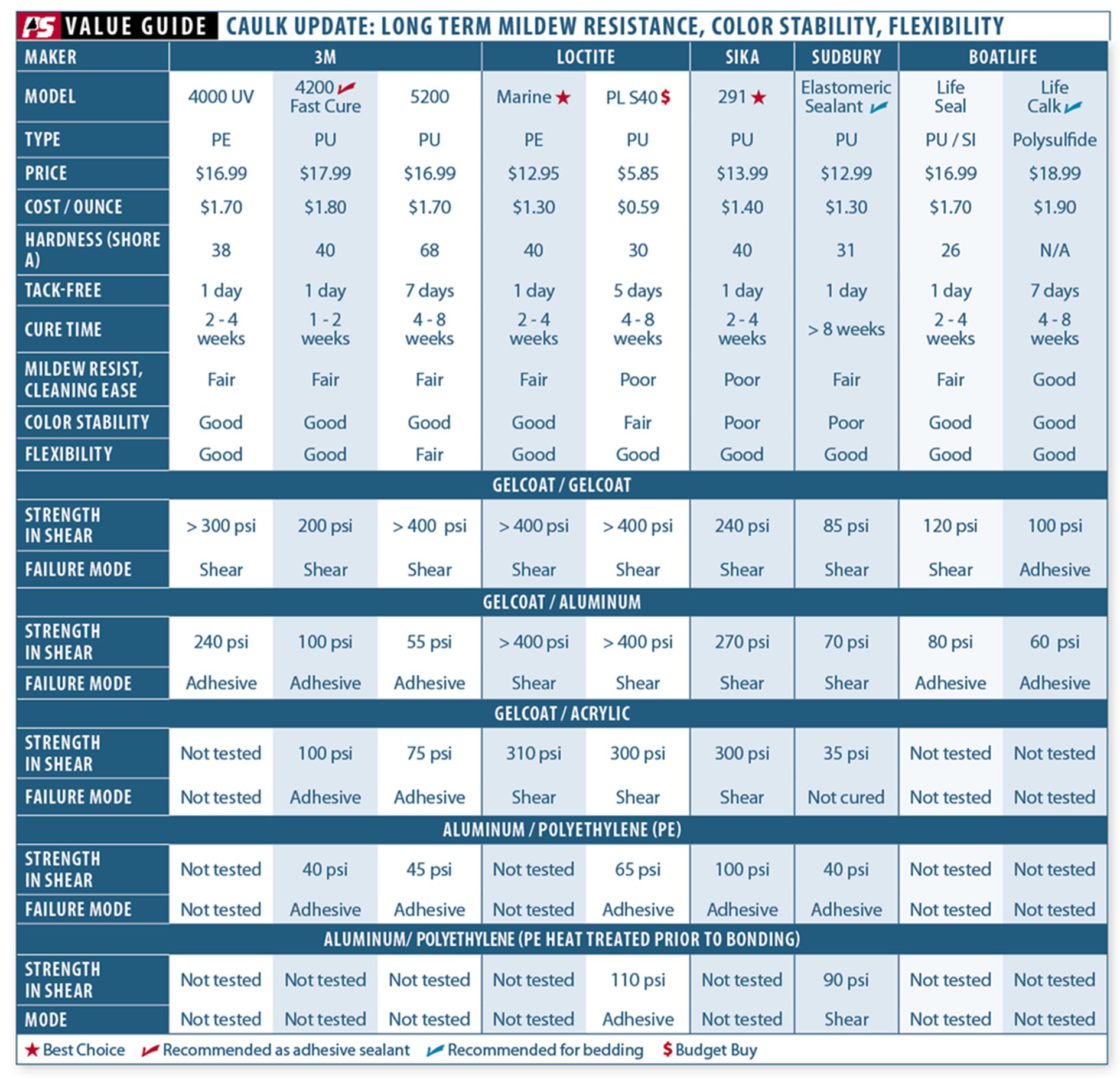

Long term mildew resistance, Color stability and Flexibility.

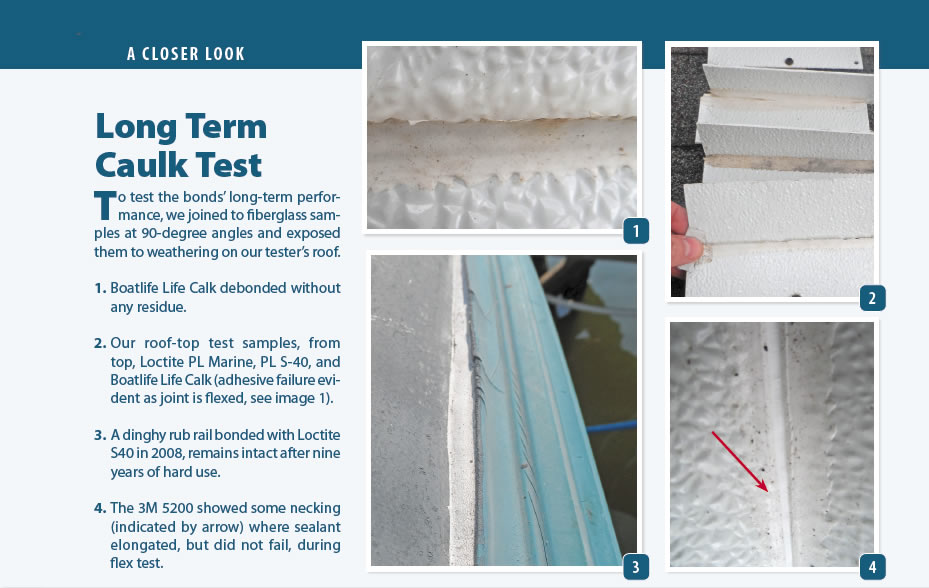

To test the bonds long-term performance, we joined to fiberglass samples at 90-degree angles and exposed them to weathering on our testers roof.

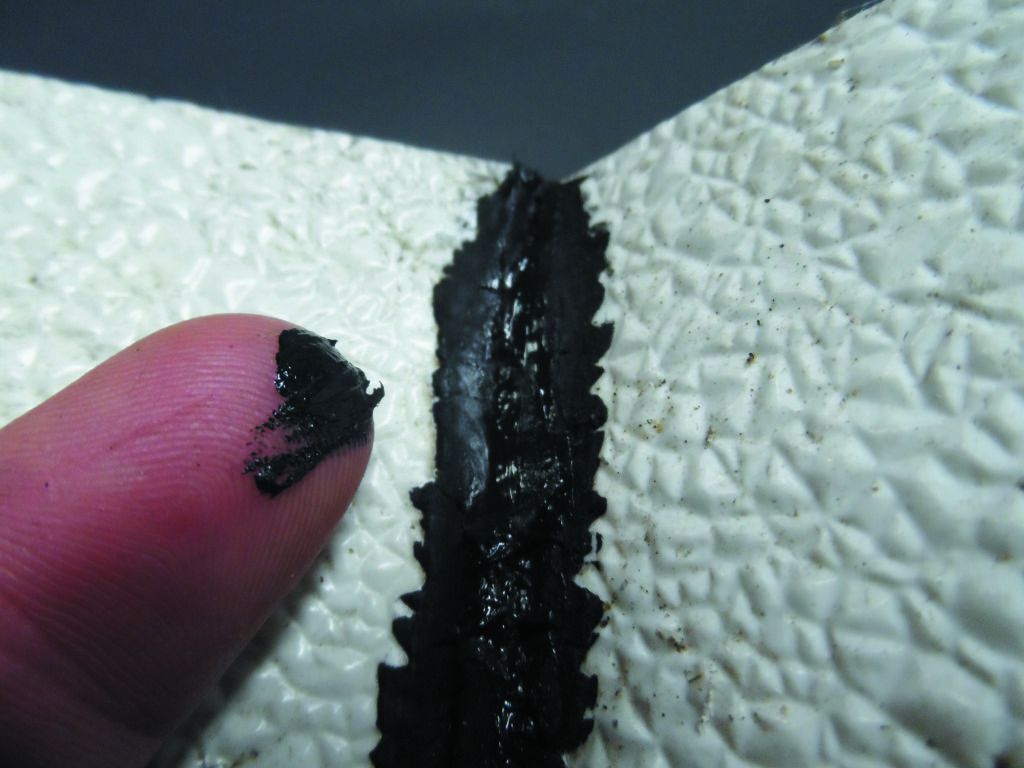

- Boatlife Life Calk debonded without any residue.

- Our roof-top test samples, from top, Loctite PL Marine, PL S-40, and Boatlife Life Calk (adhesive failure evident as joint is flexed, see image 1).

- A dinghy rub rail bonded with Loctite S40 in 2008, remains intact after nine years of hard use.

- The 3M 5200 showed some necking (indicated by arrow) where sealant elongated, but did not fail, during flex test.

how about 5200 Fast Cure

Ok, which ones do not sag? I’m trying to caulk a cap rail and most sag after heat and sun exposure.

3M fast cure has similar mildew resistance to 3M 5200. In general, 5200 is an adhesive, is not used as a sealant, and is thus not used in visible places. But there are exceptions. We reported on Mildew in a different article, “Caulks vs. Mildew,” March 2019. In general, polyether and silicone does better than polyurethane. I favor the

I assume the question was about sagging during the cure period. We did not observe any significant sagging, but we did the application at 72F. As for sagging after cure, the panels were on a very hot, black Virginia roof though the summer.

There appears to be an error in the Value Guide chart. BoatLife Life Seal was recommended for bedding in the “Bottom Line”. BoatLife Life Caulk was recommended for bedding in the Value Guide chart. Is it correct to assume that only BoatLife Life Seal is recommended for bedding? I appreciate the time and effort that went into the testing and compiling the report.

Can you clarify your recommendations on BoatLife LifeSeal and Life Caulk? The descriptions seem to be mashed together.

What caulk would you use to fillet where aluminum rail meets fiberglass deck (sun exposed)? The article is confusing….I’m guessing Loctite Marine would be the best. But since this area tends to get dirty (I used 3M 4000UV before and dirt clung to it right away and it discolored) I’m wondering if silicone is a better caulk.