Photos by Ralph Naranjo

259

While testers were endlessly scrubbing ropes for Practical Sailor’s article on the best line-cleaning methods (PS, July 2011), conversations with other sailors and rope manufacturers piqued our curiosity about using aftermarket rope treatments—like fabric softener or water repellents—to improve line handleability, reduce water-weight gain and strength loss, and to prevent lines from freezing in colder climates. Do these treatments work? Can they damage the lines? Would any performance improvement be lasting in a marine environment?

We also wondered whether any treatment would keep aging lines from squeaking as they run over blocks under high strain. The noise is primarily the result of the loss of the rope’s spinning lubricants and can be indicative of deterioration of the rope in general. We figured that both fabric softener and waterproofing treatments had the potential to replenish rope’s internal lubrication.

Some boat owners we talked to suggested that using fabric softener was normal practice, and several—but not all—cordage makers recommended using it. A consultation with another group of very particular rope users—rock climbers—revealed that special treatments are commonly used for rock climbing ropes. Although sailing in subfreezing conditions isn’t as popular as ice climbing, we wondered whether these treatments might make it more practical.

We launched a months-long field test to sort out which self-applied treatments work for sailing applications and which ones last.

Photos by Drew Frye

11

What We Tested

Test products were limited to two aftermarket treatments marketed for use on nylon ropes and polyester double-braid: Rope Proof by Nikwax, an international maker of waterproofing and maintenance products with a U.S. office in Seattle; and 2-in-1 Cleaner & Waterproofer by Granger’s, a UK-based company specializing in cleaning and waterproofing products for outdoor gear. Testers also treated some lines with household fabric softener Ultra Downy (www.downy.com) and used an untreated line as a control sample.

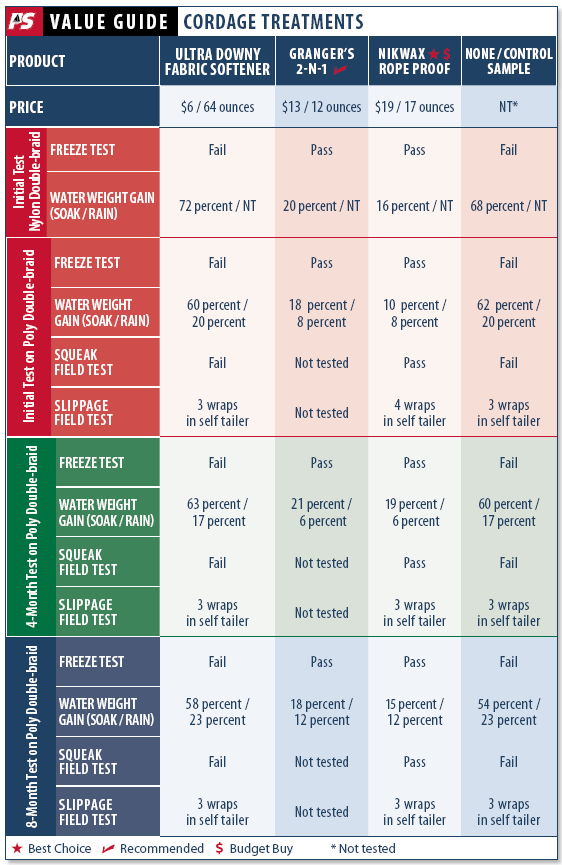

For details on the test protocol and specific test results, check out “How We Tested” and the accompanying Value Guide table.

Both the Rope Proof and Granger’s have silicone emulsion chemistry very similar to factory treatments. (Factory dry-treated ropes, like those climbers use, carry a significant price premium over standard ropes.) Dry rope treatments have been shown to have no negative effect on rope strength while rope is dry but they do help rope retain its strength when it’s wet by keeping the core dry. The same effect is expected with aftermarket treatments, although it’s commonly held (especially among rock climbers) that they are less durable than factory treatments, which typically last the life of the rope (up to five years of intermittent use, compared to two years for the aftermarket treatments).

The current crop of high-tech polyolefin (Spectra, Dyneema) lines are already very resistant to water absorption, freezing, and squeaking under load, so the treatments tested in this article do not seem relevant for use on these fibers. One treatment, Yale Maxi-Jacket, is marketed for high-tech lines, but the painted-on coating is intended to bind the cover to the core, preventing slippage on winches, so it is applied only to the portion of line that will run on the winch. We didn’t see the Maxi-Jacket as being as useful to all sailors as the products we tested, so we didn’t include it in this round of evaluations.

Editor’s Note: We do not recommend waterproofing treatments for anchor rodes. An anchor rode is supposed to sink, and water-repelling treatments tend to make lines float or at least sink more slowly.

Photos by Drew Frye

89

Fabric Softener

Testers used Ultra Downy fabric softener; however, a quick study of manufacturer MSDS information suggests that any common fabric softener would likely perform the same. Fabric softener made no important difference when used at recommended dosages. Any difference in handleability was the result of laundering, not the fabric softener.

While fabric softener does help dissipate static in extreme dry winter conditions, it doesn’t seem to bring any benefit when cleaning lines or using them on a sailboat. Additionally, commonsense suggests that the treatment would simply wash out during the first few rainstorms; if it didn’t, the buildup in clothing with repeated laundering would be horrendous.

Bottom line: A waste of time.

Nikwax Rope Proof

The recognized leader in this market, Nikwax’s Rope Proof performed predictably, easily providing increased water repellency and improved handling for a season.

A bit pricey at first blush ($19 for 500 milliliters, or 17 ounces), one bucketful of the treatment can be used to treat multiple ropes, making it more economical.

Bottom line: A worthwhile product for improving the performance and usable life of polyester running rigging, Rope Proof is a good value, earning the pick as Best Choice and Budget Buy.

Granger’s 2-in-1

Direct comparison of Granger’s 2-in-1 versus Rope Proof was challenging, since the dosage rate for Granger’s was not defined in terms of ropes but in terms of clothing. When a rope is treated at the recommended rate for Granger’s, the treatment is considerably less effective, but when we treated a small sample at the same rate as Rope Proof, the results were similar.

Although we were tempted to treat the Granger’s test samples at the same rate as the Rope Proof samples to provide a more fair evaluation, we decided it would be more interesting to follow through with the lower, maker-recommended treatment rate for long-term testing and see how it affected their durability. When tested at the recommended rate, both were effective, but the Rope Proof lasted longer—not surprising, really, since the Rope Proof treatment rate is four times higher.

Bottom line: It boils down to economy. Both products are similar in cost per fluid ounce—Rope Proof runs $13 per 12 ounces—and they perform comparably at similar dosages. Rope Proof is a good second choice.

Conclusions

While fabric softener certainly won’t hurt anything, we didn’t see any measurable improvement. Skip it.

If you want your ropes to stay a bit lighter in the rain and spray, waterproofing treatments can definitely help. The Rope Proof made a 39-percent difference in water-weight gain after a dunking—compared to untreated line—after eight months of use. It also gave a subtle, but unmistakable, improvement in handling and reduction in snarling. It seems like good stuff to use on all sheets and halyards. We presume it would reduce halyard stretch in wet weather, but we did not test this. We expect the treatments should last one or two seasons on halyards and less on sheets that spend time in the water, but re-treating sheets is easy. Cold-weather sailors will find big improvements, as treated halyards run free and sheets aren’t stuck to the deck.

Both Rope Proof and Granger’s provided eight months of solid protection. Based on our experience, Rope Proof should give multi-season protection, while Granger’s will likely protect for only one season.

Squeaking on the drum was reduced, and lines tended to slip off the drum and run through blocks a bit more easily. Both waterproofing treatments eliminated squeaking on blocks for eight months. Our test boat was quieter than ever. Will this increase the durability of the line? We’re not going too far out on a limb, but reducing internal friction and wear certainly can’t hurt, and strains will be more evenly shared by all of the fibers.

Which waterproofing treatment is most economical, and which is most durable? Given the difference in treatment rates, no absolute conclusion can be drawn. To ensure real improvements in water absorption and freeze protection, we suggest using Rope Proof at its recommended treatment rate; the product was developed and tested, and is specified for this application. We also suggest using the leftovers to treat additional lines. Although the treatments may be somewhat less effective, it makes the cost more economical, equating to only a few dollars per line.

Given the benefits of an almost 40-percent reduction in water weight gain, significant improvement in handling and running through blocks, and reduction in internal friction, rope squeaking, and wear, these treatments should be a standard part of cruisers’ line maintenance regimens, and they are a clear win for low-budget racers.

For the fastidious owner who wants the ultimate in clean, easy-handling docklines, factory dry-treated lines absorb less water, making for more comfortable docking in cold weather.

You make no mention of extending a ropes useable life. Do any products provide UV protection? If I can prolong the life of my lines it’s well worth the cost of treating.