Simple ferrous-metal oxidation is a process in which iron, oxygen, and water chemically react, and it can cause rust to seemingly weld fasteners together. This unyielding grip often turns disassembly into much more of an ordeal, but with a few, regularly available products and a good set of wrenches, the big battle becomes a minor squabble.

My fastener coercion kit has changed over the years, but the gameplan remains the same. First, I attempt to strong-arm loosen the offending nut or bolt using a hex socket and a half-inch drive. This hex socket mates more effectively with a six-sided nut or bolt and affords more contact surface and less likelihood of deforming the nut or head of a bolt.

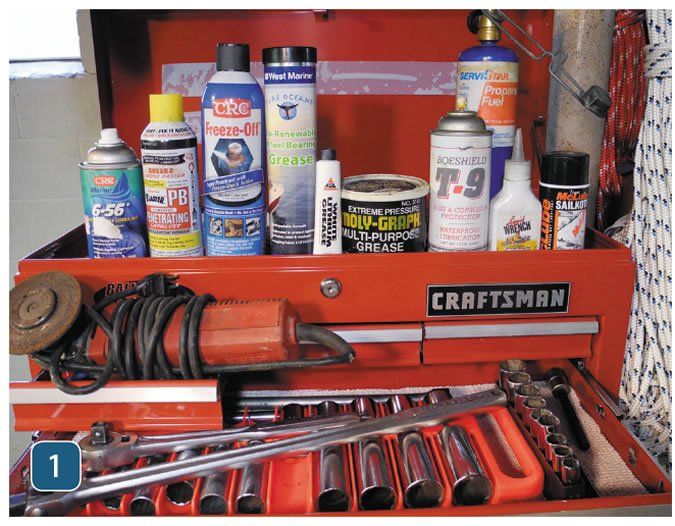

If reasonable torque doesn’t do the job, I switch to penetrants before increasing the torque with a longer handle (breaker bar). At times, Ill first clear away some of the rust with a wire brush and perhaps even use some diluted muriatic acid to dissolve the corrosion. Next, I soak the offending fastener overnight with Liquid Wrench and resume the unloosening process the next day with a breaker bar and socket.

Smaller-diameter fasteners can be snapped in this process, and if that frees the hardware, all is good, but in many cases, breaking a fastener can turn a simple project into a major repair. A common example of this is the hinge-assembly bolts on a Catalina 22 swing keel. If these bolts are broken during removal, and you can’t remove the remaining threads, a new hinge-retaining assembly (including fiberglass repair to install them) might be required. Even if you can remove the broken bits with a drill-and-tap kit and an easy-out, you have added hours to your project. Thats why I still hold back a little on the second attempt, favoring less torque in an effort to keep the fastener intact.

Step three, when necessary, use a combination of heat and cold. I use a simple propane torch to heat up the surrounding area and expand the metal. I don’t aim to create a red hot surface, just a moderate heating of the surrounding metal followed with an aerosol dose of PB Blaster or CRCs Freeze Off on the part Im trying to remove. Heat expands the surrounding metal, and the cold minutely shrinks the stud. This combination of sprays can be particularly effective. Freeze Off creates a cold surface and adds penetrating oil. The change in temperature also causes enough dimensional change to allow the PB Blaster (one of the more effective penetrants weve tested) to enter micro fissures around rusted threads and to facilitate loosening.

If none of the efforts mentioned above leads to success, I look to cutting off the bolt head or splitting the nut with a nut-splitter and driving out the fastener with a drift. Really high-quality hacksaw blades, specialty nut-cutting tools, and various thicknesses of grinder discs all fall into this kit of last resort.

Sometimes I use a ballpeen hammer, a small sledge hammer, or even a pneumatic impact tool to loosen up a rusty thread-to-thread union, but care must be taken with such heavy-duty bashing.

During reassembly, I coat new threads with graphite grease or a product like Bostiks Never-Seez. I also use white Lithium grease in areas where the stickier, more tenacious, heavy-duty coatings are a problem.

The threads of the trailers screw jack pads also get some white grease; the corner jacks get a dose of CRC 656 after each post-submersion rinse-down; and the wheel bearings get new grease pumped through the hubs annually. I also spray some Boeshield T-9 on electrical connectors before and after a launching or haulout, and the job is done.