Past articles and our recently published e-book on anchoring prompted a wide variety of questions from readers regarding anchor snubber length, material, and diameter. To answer these questions, I’ve sought to create a simple formula for determining the correct sizing and material. The formula is not meant to be definitive, but part of ongoing work. Practical Sailor welcomes more input on this topic.

An anchor snubber reduces loads on the anchor and boat by adding elasticity to the rode. Usually made of three-strand nylon, the snubber joins a strong point on the boat-typically a cleat or a bit-to a point on the anchor rode. In between these two points, the rode is looped and left slack. Too much stretch, and the snubber breaks or the chain pulls taught; not enough stretch, and it absorbs little energy.

There is a wide range of pre-made snubbers available at chandleries or online, and there is an even greater variety in use. To simplify, I’ve grouped snubbers into two categories: short and long.

Short snubbers: For our purposes, a short snubber is one that is less than one-quarter of the boat length. A short snubber is fine for reducing grinding noises transmitted up the chain and can reduce loads on the anchor, deck hardware, or windlass in moderate conditions. However, a short snubber will be more prone to fatigue and failure when conditions deteriorate. Increasing the snubbers diameter may keep it from breaking, at the expense of increased peak loads on the boat and anchor.

Long snubbers: Long snubbers of 20 feet or more allow for more stretch. In addition to reducing the load on the anchor roller and protecting the windlass, a long snubber can reduce peak loads in a squall or storm by 50 to 70 percent. However, in order to function best, the snubber must be matched to the boat and ground tackle.

Based on his research, I established a broad target for a good working snubber: The rope should stretch between 3 and 6 feet at 20 percent of its breaking strength (the snubbers safe working load) but still be a manageable length. Although three-strand nylon is popular, complaints about twisting and chafing turned my focus on nylon-plait snubbers, nylon double braid and recycled climbing rope.

The on-the-water testing took place on a 32-foot catamaran (windage roughly equivalent to a 40-foot monohull). The tests mirrored those carried out previously for Practical Sailor on a 38-foot catamaran (see PS November 2013 online).

Another question I sought to answer was how frequently the snubber should be replaced. Because snubber lifespan can vary wildly according to usage, he took a conservative view. Based on the projected cycle loading in an anchorage so storm swept that no sailor would want to stay for long, he determined that full-time cruisers should replace their snubber every two to three years, while the seasonal or part-time cruiser can get five to eight years of use from one. Those who anchor in well-protected areas will see less fatigue, but in these cases, environmental damage (UV rays, acid rain, etc.) would also be a factor. The surprising effect of weathering on nylon ropes lifespan and strength was covered in a previous issue.

Although every anchoring situation and boat are different, Frye’s testing and research yielded the following formulas. Since we posted the formulas several sailors have discovered the formula doesn’t work for them, we can usually sort this out via e-mail.

These calculations can’t be expected to produce a perfect fit for every boat or situation, but they represent a reasonable place to start. If the formula is not working for you, just use the tables and the closest boat to yours for reference. (If there’s a boat you can’t match enter the specs in the comments below, or email practicalsailor@belvoir.com) You can decide to lengthen the snubber or exceed the calculated diameter to add strength or abrasion resistance, but be aware that if you choose to shorten the snubber, this will result in higher peak loads. Certainly, countless sailors have cruised thousands of miles using shorter snubbers than we recommend here, but in our testing and research, short snubbers are associated with the most failures. Don’t overlook chafe gear (there are multiple chafe gear reports in the archives), as this is an essential element in the snubber setup.

Frye’s Snubber Length Formula

Double-braid or brait nylon snubber length = 1.3 x boat length. For dynamic climbing rope, snubber length = 1.1 x boat length. These are minimum snubber lengths; longer is better, up to about 60 feet.

Frye’s Snubber Diameter Formula

Snubber diameter (in 1/16 of an inch) = 16 x 0.00067 x (length overall in feet) x (boat’s loaded weight in pounds)0.3

(Round up for the nearest available line diameter.)

Multiply this by 1.6 for catamarans to compensate for added windage. For two-leg bridles, multiply the final diameter by 70 percent. (One leg will occasionally carry the load, but this is offset by reduced yawing.)

We are interested in reader feedback. If you have some snubber details, or tales of snubber horror or delight to share, or are having trouble using the formula to estimate the right size, just email at practicalsailor@belvoir.com.

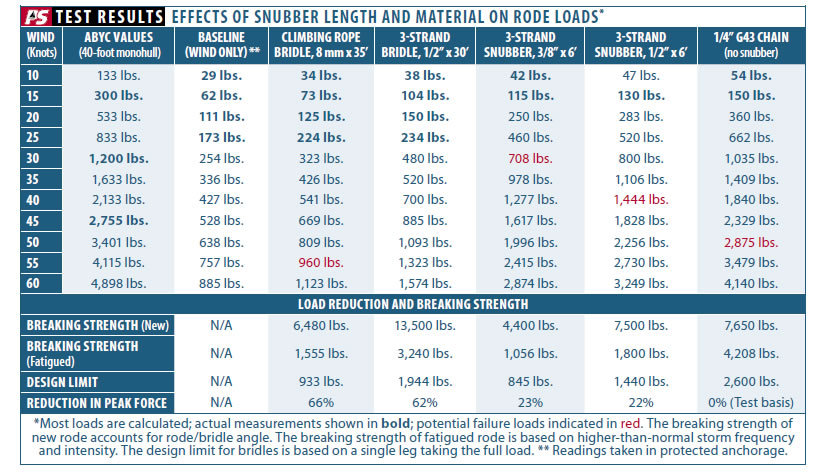

Notes: Baseline loads (wind only) were recorded with a stretchy snubber (8-millimeter climbing rope x 60 feet) in a well-protected anchorage. All other values represent peak loads on a PDQ 32 at 10-minute intervals. The test area had an eight-mile fetch to windward and was approximately 7-feet deep. Tandem anchors were set to eliminate dragging; quarter-inch G43 chain was used for anchoring. The scope was 7:1. In winds over 25 knots, there was no catenary in the chain. For winds above 25 knots, the calculated loads should serve only as a very rough guide. Wave action will make this data highly variable. Our no-snubber data agrees closely with the ABYC’s figures, which are regarded as conservative. Design limit is the peak rode load at the snubber’s working load.

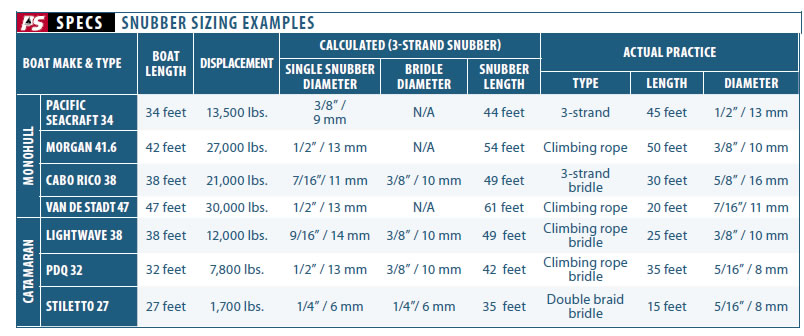

This table compares snubbers calculated using the formula described in this article to those in actual use by experienced cruisers. Note than many boat owners opted to go shorter than the calculated length and that several opted to use dynamic climbing rope.

For more information on climbing rope types and sizes, see our report on using climbing rope in the mainsheet traveler, “Testing a Dynamic Traveler.”

Hello,

very interesting topic.

Only problem I have is that using the formula I do not get the snubber diameters in the table, ie. for the 47‘ van de Stadt I calculate 0.69 inch or 17.6mm which differs quite a bit from 13mm.

Is the formula wrong?

Dietmar

SY Greyhound

I think there must be a glitch. The article says ‘(in 16ths of an inch)’ but when I do it it comes up with .43, which would mean less than 1/32 of an inch. I’m not sure I would be happy unless it was some alien fibre (like superman’s costume perhaps?)

Snubber diameter = .00067 x length in feet x weight in pounds

= .00067 x 50 x 36000

= 1,206 (in sixteenths)

= 75.4 inches????

I made the same mistake: weight in pounds to the power of 0.3

We’ve corrected the formula in the text. If the size still seems incorrect, Drew suggest referring to the table and using the closest boat in size (rounding up, as needed) as a reference. If you have a particular boat in mind — just email the specs to practicalsailor@belvoir.com and I’ll plug it into the Excel table, give you an answer and include it (or a similar boat) in an expanded table.

Would appreciate a better explanation of the type of climbing rope used. Guessing it’s the elastic (shock cord) vs the direct ascent rope used for climbing a mast? Sorry I don’t have a lot of experience with climbing ropes.

Within the text, we’ve added a link to this article, which gives a general explanation of the different climbing ropes. https://www.practical-sailor.com/sails-rigging-deckgear/testing-a-dynamic-traveler

Climbing rope is nylon with a very tightly braided cover and a parallel core. This makes it slightly stretcher and considerably more abrasion resistant than conventional nylon double braid. It is NOT like a bungee cord–static stretch under body weight cannot exceed 10% and is typically closer to 5-6%, though stretch to failure (5000-6000 pounds) can be 80-100%. The 9-10 mm climbing ropes described are what climbers (and stores) refer to as UIAA single ropes.

I’d appreciate your opinion. After a couple of days on anchor in winds gusting 40knots our brand new snubber has permanently stretched by 10%. 3 strand nylon, 14mm diameter, 5 metres original length. Boat is a 50ft monohull, 20 tonnes displacement. Should I replace the snubber? Looking at the table 14mm seems sensible. However I’m not sure I’d want a much longer snubber as I regularly anchor in 5-10 metres depth. Many thanks!

Some of the outer strands seem to have failed also. Not masses, but a few ‘hairy’ fibres sticking out.

It’s impossible to know what the actual tension on the snubber was. Much depends on wave exposure, how much chain was deployed, and how the boat was moving. That’s relatively heavy boat and a short snubber. I’m guessing frequent peaks over 1,000 pounds.

14 mm rope has a break strength of about 9,000 pounds, but with splices, bends an abrasion, 6-7,000 is more realistic. The working load limit of nylon is about 12%, depending on how long a life expectancy you want, or about 720-840 pounds in this case.

There is always some permanent elongation on a rope that has been loaded to the working load limit. In the case of 3-strand rope with splices in the ends, 6-8% would not be considered excessive. This is the result of the splices and fibers settling in and some microscopic changes within the fibers. Stretch greater than that is the result of small scale damamge to the fibers.

The suggested snubber size (see above formulas and examples) for a boat of that size and weight is about 18-20 mm and at least 30 feet long and preferably 40-60 feet long. This is a heavy boat. The current snubber is working beyond it’s load limit, and 15 feet is much too short to absorb the energy. We would predict failure of the current snubber within a few storms, depending on severity and exposure.

THANK YOU that’s very interesting indeed. I hadn’t understood the ‘working load’ 12% principle until now, rather assuming that the peak load would be well below the breaking strain etc. I will replace with a heavier and longer rope as you suggest.

Working load vs. break strength is an important concept. Steel can withstand repeated loading to about 50% the breaking strength without damamge, and to be conservative, the working load is generally set at 20-33% of breaking strength. Kept within this working load limit, steel parts do not exhibit fatigue, even after many thousands of cycles.

Under perfect conditions nylon can withstand 20-25% of breaking strength for thousands of cycles, but 10-12% is generally used as the working load limit to reflect realistic conditions and experience. Ropes made of polyester or Dyneema have higher working load limits, typically 25-35% of breaking strength. However, textiles still wear, staying below the working load limit does not mean the rope is not fatiguing. It just means it should last until abrasive wear and UV damage catch up with it first.

“These are minimum snubber lengths; longer is better, up to about 60 feet.” Why the limit to around 60 feet? I saw nothing in the article about this. I have a friend with a 60 foot steel boat that wants to put 2 90 foot snubber lines on so he can tie them at the stern.

Primary concern is chafe. Possible to reduce by only running through blocks. This deckside snubber seams more common on larger frequently steel vessels permanently captained. Chafe therefore being examined daily.

Great work on this. I have a Mantus small bridle for my Beneteau Oceanis 35, which, according to this work, is too short (23 ft) and too thick (5/8″). I should go with more like 3/8″ to 1/2″ and twice as long!!

What about the idea of adding a mooring compensator (or two) to the arms of a bridle? There are some on the market (Unimer U-cleat?) at would seem to add even more stretch than the line stretch itself, and at loads that look relevant according to the article.

Yes, 5/8″ is a pretty stiff snubber for that boat. Mantus is designed for ultimate durability rather than shock absorption.

Please read “Anchor Snubber Shock Load Tested,” November 2013, where this is tested and discussed at length. The short answer is that a few more feet of nylon is simpler than adding another component.

We’ve done some testing, stretched some ropes, and there should be an article out on this topic in near future.

Some concerns about permanent elongation of dynamic climbing ropes. My understanding was once used as a fallstop they should be replaced. Fallstop loading created permanent elongation and this drastically reduced shock absorption capacity.

Some climbers and rope manufacturers have new measured marks and an allowable stretch % before retirement. The design is supposed to reduce rebound that is harmful in a fallstop. Climbing and construction fallstop information ingrained in me. I was suspicious of manufacturers on their ‘just buy more’ replacement so I long ago researched ‘why’.

I am not saying they can’t be used, just I don’t think the design and performance changes are being considered. 3 strand nylon for example is achieving stretch by compaction as well as fiber stretch. Much like winding a rubber band airplane compared to unwound loop.

Interesting attempts to quantity the beast of a storm and wave battered boat.

The “once used as a fall stop” is an internet oversimplification. Primarily, it depends on how severe the fall was. Gym ropes routinely take thousands of moderate falls before retirement. Only falls that are near the energy absorption limit of the rope take a serious toll, and unless the rope will see another high factor fall (ropes for top roping and gym use will not) the rope generally has sufficient fall capacity remaining until it is too fuzzy to feed through a Gri-Gri.

Climbing and construction fall stop technologies and practice are virtually unrelated, except by gravity. The first is based upon elasticity, friction across biners, and give in the belay system, and the latter on consumable devices. They don’t compare well and are best not considered or discussed together. Snubbers are more related to climbing rope use, and more like the top roping and gym case than the massive lead climbing whipper case.

Yes, permanent elongation is an important metric of rope life, and we will be reporting on that.

Re. Maximum snubber length. No, there really is not upper bound. Boats anchor with all rope. But above about 60 feet we are looking at diminishing returns. First, the chain catenary does provide some shock absorption, just not enough. Second, we have collected some data that supports that too much stretch can lead to increases yawing, and the yawing increases the rode tension and side-to-side wrestling on the anchor. Every situation is different, but like the springs and shocks on a car, there is an optimum “softness” of the suspension, beyond which things get worse. Consider being anchored by a 200-foot bungee cord; the motion in waves would get crazy and you’d spend some time sideways.

Very cool! I have been trying to advocate the advantages of elastic snubbers that stretch by 1-2 metres under heavy load for some time, but with limited success. An all chain vessel will strongly benefit from it when anchoring in shallow water, where a chain cannot store the shock load energy anymore. This will affect those vessels most that are impacted most by a swell or gust. A heavy compact displacement vessel that just stays put, no matter what, is thus less affected than a smaller vessel, or a multihull, which gets going with every gust / swell.

Cheers, Mathias

Dear Drew,

English is not my native language so please can you give me an advice.

Hanse 470E 12.500kg (47 feet)

I am doubting between a V-briddle and two separate (port, starboard) briddles combined at the end. Two separate ones being easier to make and extra safety option.

1. What would be your advice?

2. I was thinking about 25-30 feet lenght and (5/8) 16mm for the V-briddle.

3. Will (5/8) 16mm be to much when using 2 seperate ones?

Thank you very much, John

This is very helpful. As i’m not in Nth America, converting to metric is doing my head in.

Another great article from Practical Sailor!

Thank you!