Photos by Frank Lanier

Cracked nylon thru-hulls are a common problem, as a walk in almost any boatyard will bear out. Unlike fittings constructed of industry approved materials (bronze, Marelon, etc.) nylon thru-hulls are not recommended for use at or below the waterline. Age often plays a factor in the failure of nylon thru-hulls, but ultraviolet light is the main culprit. While different brands vary widely in their susceptibility to UV damage, some are so poorly made they can fail within the first year of use. The stress placed on the thru-hull by an unsupported hose can also cause failure, with the weight of the hose acting like a lever as the boat bounces around while underway.

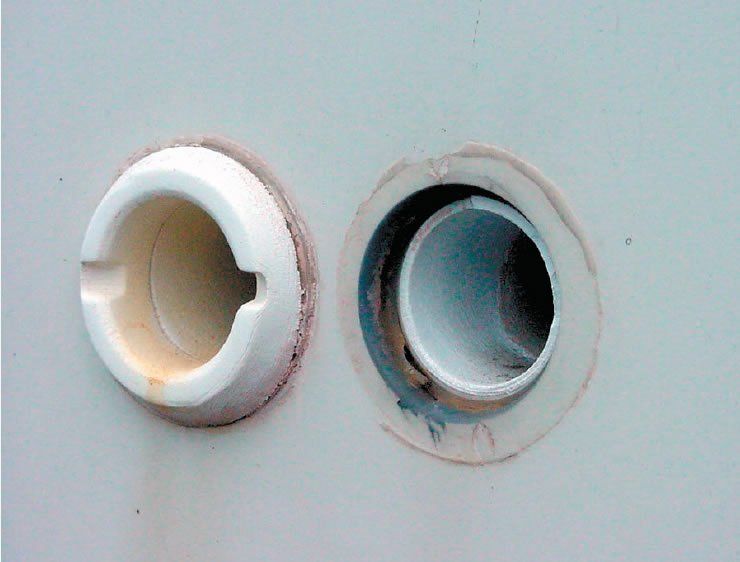

Nylon thru-hulls typically fail where the body of the fitting joins the outer flange, which can result in a crack or even total failure (both of which are shown in the accompanying photo). Once the flange shears off theres nothing left to keep the through-hull in place, meaning itll eventually be pulled inboard, leaving a gaping hole in its place.

If located near the waterline such a hole can reduce the vessels effective freeboard from feet to inches, meaning a boat needs only to settle slightly before it begins to take on water and sink.

If the failed fitting happens to be your bilge pump overboard discharge, then the pump just continues to recycle any water that enters the bilge as your boat gets lower and lower in the water until…well, you get the idea.

Nylon fittings should be inspected at least annually. If you find one fitting thats bad and the others are of the same vintage, play it safe and replace them all.

Photos by Frank Lanier

Nylon thru-hull fittings like this are culprits in more than a few sinkings, when used as cockpit drains that ended up underwater and were cracked due to age and UV damage. Nylon is most definitely not for below-waterline use.

Nylon should not be confused with Marelon a high strength, polymer composite, developed as a solution to electrolysis and corrosion problems associated with bronze/brass plumbing fittings. It is UL/ABYC approved and ISO certified for use below and above waterline.

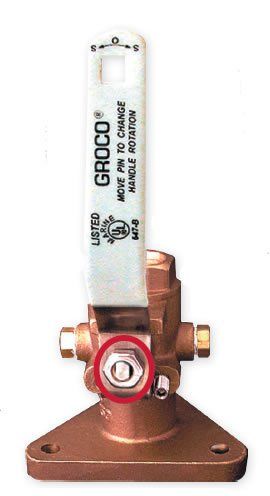

All approved seacocks and through-hull fittings, metallic or composite, should carry the UL approval number 1121 or 618C, for Marine Through-Hull Fittings and Sea-Valves.

Capt. Frank Lanier is an accredited marine surveyor with over 30 years of experience in the marine industry. His website is www.captfklanier.com.

Editor’s note: [3.10.2018. This text has been edited for clarity.]