Polyester sailcloth is amazingly strong and durable stuff, often completing trips around the world or decades of weekend sailing. Its Achilles heel is the sun. After just 2-3 years in the sun, depending on the latitude, it becomes so rotted by UV that its little stronger than a cotton bed sheet. Mainsails are safely bundled under a Sunbrella cover. Nylon Spinnakers are bagged and stored below. Genoas, on the other hand, remain furled on the headstay, often year round, with the last 12 inches of the leach and foot continuously exposed.

The standard solution is a sacrificial UV strip. Heavy covers of Sunbrella or Weather Max are the standard, often lasting a decade if the stitching holds, and providing virtually complete protection. The downside, is that these covers are heavy, affecting the trim of light air sails. Unless the very best UV resistant thread is used, the stitching often fails within 4-6 years, requiring expensive re-stitching. Either way, replacement at about 10 years is common, at 20-30 percent of the cost of a new sail. If the sail has stretched and will be due for replacement in the few years anyway, does it justify this investment, or is the money better saved towards a replacement?

UV sailcloth is another option. It is lighter than Sunbrella but considerably less durable. Four to six years is as long as it will last, after which it falls to tatters. Self-adhesive polyester insignia cloth is a lightweight solution. This sail tape should last three to five years, after which the sailmaker will curse the nearly impossible job of removing the adhesive it leaves behind. Neither protects the sail as well as Sunbrella and some damage to the leach can be expected, particularly if the cover is allowed to fail, which is commonplace due to the short life expectancy. White covers provide 10-20 percent less UV protection than colors.

Sail Paint Potential

What about paint? Volvo Ocean Race sails are boldly painted with sponsor logos. North and Doyle have been offering paint as a UV protection option for over five years, though it is a specialty item, typically reserved for light air sails and mega-yachts. A number of budget cruisers have reported success using plain common acrylic house paint to polyester sails. Although they experienced some chipping after a few years, it was easily touched up and lasted five years between re-coating. If the sail was stretched and destined for replacement, this made more sense to these budget-conscious cruisers than paying for a new cover.

And what about the light air reachers and code zeros that more and more cruising boats are sporting, perched out on bowsprits? Often they come without UV protection since it is assumed they will be stored out of the sun, and yet, because of their awkward position on the bowsprit, its common to leave these rigged for days or weeks. For laminates, even a few months of cumulative UV exposure is a lifetime and a year will cause considerable weakening. A heavy canvas UV strip is a non-starter; it disrupts proper sail shape in light winds, and more seriously, creates a stiff hinge point which will fatigue and tear laminate sails (see Making Sail Repairs Last, PS November 2018). Perhaps a coating can provide lightweight, non-damaging, and economical UV protection that a DIY can apply.

Paints and adhesives have come far. The first latex paints, introduced in the 70s, adhered poorly and lacked durability in the sun. Automotive paints had to be waxed if they were expected to last even a decade. Now we have coatings that can last 20 years without effort. Perhaps it is just a matter of ferreting out the right product. While we had no expectation that any could match the durability of acrylic canvas, a five-year coating life doesn’t seem far-fetched at all.

What We Tested

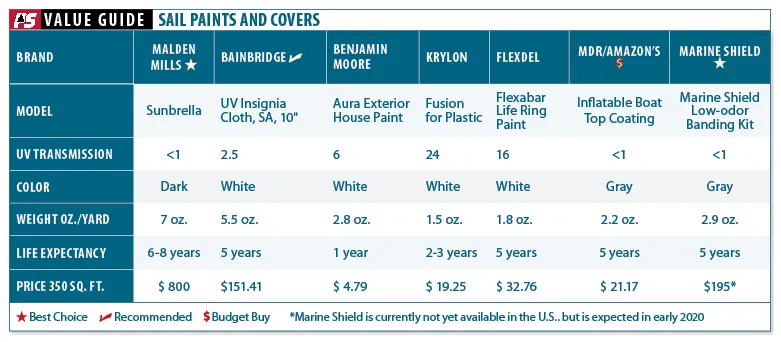

We tested a variety of paints, including Benjamin Moore house paint, Flexabar Life Ring Paint, MDR/Amazons Inflatable Boat Top Coating, Marine Shield, and a Krylon Fusion for Plastics. We tested other spray and latex products that adhered so poorly when flexed that they did not advance to panel testing.

How We Tested

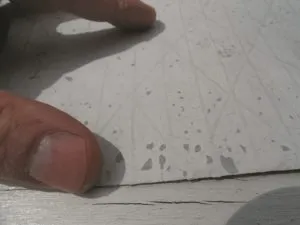

First, we applied each of these to polyester and laminate sailcloth that had been exposed to sun for three months. After one year, the samples were put through a simple flogging test by placing 10-by-12 inch flags on the roof of a car and driving at highway speeds for 20 minutes. Those that did not peel extensively were painted onto the leach and foot of a Mylar/taffeta jib and put into the field test.

Adhesion was a key characteristics we sought in a sail paint, but we were also interested in opacity.

Photos by Drew Frye

Observations

Previously, our test boat had a Mylar/laminate jib with a Sunbrella cover that had been added at some point in its life. On one hand, this created a weak hinge in the leach where two different materials meet. On the other hand, as the Mylar began to fail along the foot, the fabric cover held it together, extending the life of the sail. This benefit is likely unique to heavy acrylic covers, since the other materials will lose structural integrity before the sail; the Insignia Cloth and UV polyester covers weve seen were too rotted to add support.

Another problem with sewn covers is that older sails, particularly laminate sails, don’t react well to a row of needle holes. Its like adding a tear here line. The older laminate sail used for the paint tests would never have withstood sewing, since it was already developing micro-tears.

An unexpected objection of lofts to both adhesive repairs and painting sails is drying time. Loft floor space is at a premium, and they are unwilling to tie it up for a low-value project. They get paid more to lay down stitches than for painting. This is probably the primary reason paint is only seen on mega yacht sails and sponsored racing sails. Odor in the loft is also a concern, but do-it-yourselfers work outside.

Before beginning the physical stage of the test, we painted 10-by-12 inch samples of polyester and laminate sailcloth and placed them on a test rack in the sun to sort out the clear losers. Common spray paints, including products from Rustoleum and Plasti-kote, peeled too easily when flexed. We tried a variety of coatings on Mylar sailcloth; all peeled rather quickly. In fact, no sail manufacturer recommend painting directly on Mylar laminates. It was their feeling that Mylar sails were purely for day racing and would not be left on furlers. However, paint will stick to the polyester scrim, and that is what we tested. If some UV protection was desired, thin Tedlar (polyvinyl fluoride) film has been used, although it is no better than the poorest paint. Sailmaker experiences suggest that even polyester sails will last no more than 4-5 years with a Tedlar cover, after which the sail is ruined.

Paint was heavier than expected. Its lighter than Sunbrella, but not materially different from the lighter fabrics or films.

Light colors are not very effective, in either cloth or paint. The obvious answer, based on the MDR paint and blue Sunbrella, is to use darker colors (Sunbrella has tested their full range of colors-only the off-white hues transmit more than one percent UV).

We only exposed samples for one year, so only the un-coated laminate and Fusion-coated laminate (24 percent UV transmission) revealed any weakening during the flogging tests. None of the polyester samples were degraded.

Paints performed better on polyester sailcloth than on the polyester scrim side of the laminate. House paint began to crack while still on stationary laminate panels, making it a clear failure, although it did better on polyester sailcloth, only chipping when flogged. Fusion stayed on the polyester cloth reasonably well, but chipped from the laminate cloth during heavy flogging. Marine Shield and MDR/Amazon remained undamaged even as the laminate cloth began to fail.

For on-boat testing we chose Inflatable Boat Top Coat from MDR/Amazons. Our selection was based on PS comparison of inflatable paints (PS August 2011), seven years experience of using paint on a Hypalon tender, and encouraging results during the panel exposure and flogging tests.

The best application tool is a foam mini roller, with a small brush to work around eyes and leach line cleats. Blue masking tape sticks well enough if rubbed down. The test sail was a laminate sail with high modulus fibers bonded to mylar, with taffeta on both sides. The sail had been equipped with a UV Dacron cover, which was at the end of its life. The sail was beginning to develop holes and tears along the edge of the UV cover, the result of both UV damage and flexing along this line of increased stiffness.

Tape seems like simple thing to manage. How complicated can it get? But as we’ve found in multiple past tests at Practical Sailor, the type of tape you choose, and how you use it determines the quality and durability of your work.

We’ve carried out multiple tests of sail repair tapes, most recently in 2018 (see PS June 2018, “Simple Sail Repair”). In that report we found that Sailrite (www.sailrite.com) had the right stuff for just about any repair, but we also discovered the importance of prepping the surface before taping. Our report on masking tape explored the various types of tapes—long term vs. short term, normal edge vs. fine line, etc.—and their uses (see PS October 2013, “3M Masking Tape Matchup”).

Photos by Drew Frye

We did not remove the existing self-adhesive UV cover because the sail would be damaged in the process. Instead, we repaired the damaged areas by reinforcing the area on both sides of the old cover with 4- to 8-inch wide strips of self-adhesive UV Dacron Insignia Cloth from Bainbridge. We also covered an 18-by-8 inch area from the clew up the leach where UV damage and abrasive wear were evident. Because we saw UV damage beyond the edge of the existing cover, we applied the paint about four inches wider than the original skimpy protective sun cover.

After a season of furling, unfurling, tacking, and flogging, not a single chip has appeared. Rubbing across the spreaders has had no visible effect. The leach was stiffened slightly, more the result of reinforcements than paint, but it still furled well. From a distance it looks like Sunbrella, and none of our dockmates noticed the difference until we pointed it out.

What about protecting the stitching? The paint may wear off the high spots. On the other hand, the paint penetrates inside the thread and may continue to provide some protection, much as we have seen with polyurethane rope anti-chafe coatings. Were going to keep a close eye on this.

Benjamin Moore Aura Semi-Gloss

Although we know this exterior house paint to be a top-quality product for its intended purpose, it began cracking on the stationary panels in about 6 months. About 85 percent came off during the flogging test.

Bottom line: We werent surprised. Save this for your house.

Krylon Fusion for Plastic

The only spray paint that bonded well enough to be included in the test, it is marketed as bonding well to plastics. Although it fared better than house paint, it lost 35 percent of its coverage during flogging. It allowed more cloth damage than any other coating, probably due to its high UV transmission (24 percent).

Bottom line: Save this for the patio table.

What’s that they say about the 10-foot paint job? Sure, if you look closely, it is clear that something is different with the genoa aboard Tech Editor Drew Frye’s F-24 Corsair. Battleship gray is not a common color for the suncover on a recreational sailboat, and the sheen is more reflective than normal. But unless you are aboard the boat, the laminate sail looks like any other genoa with a stitched on suncover. The original suncover exists, only now it is painted.

Photos by Drew Frye

Flexabar Life Ring Paint

Solvent-based, this was sticky and a little messy to work with. We were concerned that the solvents might damage the fabric, but it did not and the cloth performed very well in flogging tests. Opacity was poor, UV transmission in white was high (25 percent), and it seemed to attract dirt.

Bottom line: Wed use it on a life ring or LifeSling bag, but not for sails.

MDR/Amazon Inflatable Top Coat

We selected Top Coat for long-term testing on our F-24, based on a flawless performance in the flogging test and wide availability. It rolled on easily, giving two-coat coverage rate of 500 square feet per gallon. The paint is available in gray, light gray, and white, all with flat gloss. Weve had this on the water for a season and have experienced zero chipping. Weve also used this product on inflatable dinghies, where is required recoating after 5 years. While a sail and a dinghy have different coating requirements, we expect similar performance on sails.

Bottom line: Our Budget Buy for UV covers on sails.

Marine Shield

The lone sail-specific paint in this test, Marine Shield lived up to our high expectations. Its performance in the flogging test was flawless. The coverage and appearance of this paint were very good, with very little light passing through. The only observable difference was higher gloss. Marine Shield is also slipperier, which should give it some advantage in furling and storage. The New Zealand product is not yet distributed in the U.S., though this is plannd for early 2020. For information on the product, contact the maker-see Contacts box on page 12.

Bottom line: Our Best Choice for a sail paint. Hopefully, it will become more widely available to DIY sailors.

Paint will stick to anything—for a while. But the real test comes over time. Fabric, because it is a flexible surface that can absorb water, presents multiple challenges for a coating. Our biggest concern was flogging. If we can’t prevent the varnish on our grab rail from cracking after eighteen months, how can we expect any coating to adhere to a stretchy, pliable surface that is exposed to the elements—storms, high summer temperatures, freezing cold—year in and year out? To answer this question, we fit the test rack to the top of our vehicle and drove at highway speeds for 20 minutes.

Photos by Drew Frye

Conclusions

This is not a project wed recommend for the average cruising sailor. For most people, sunbrella and Weather Max remain the gold standard for heavy duty UV covers for sails that live on a furler. The cloth outlasts the stitching that holds them, UV blocking is superior, and they provide physical protection and support. No other material offers this combination. But this protection is relatively heavy and expensive to replace.

UV Dacron and Tedlar films offer a lighter weight option. Self-adhesive fabric seems like a great DIY replacement option, but durability isn’t much better than paint, and sail shape can be affected when self-adhesive tapes are installed over large areas. This is particularly problematic with laminate sails and sails that are seriously creased and wriinkled.

We see a lot to like in using paint for old sails. It demonstrates good UV protection and surprising durability. The relatively low price make them a valid DIY option for the sailor who would rather save his beans for a new jib in five years than invest in a sewn cover for an old dog that is stretched out of shape.

We also see value of using paint on laminate sails that live part time on a furler, so long as you recognize that the UV protection is not perfect and that the sail should be put away when you are away from the boat for a few days.

The true test will be durability over the next few years, but so far our experience with paint has been good.

Great article. Who will be distributing the Marine Shield?

Bob

Which issue carried Painted Jib? I was a subscriber for the time it was printed, but I can’t find the article.

Good info. I have an almost brand new North genoa (lightly used half a season) and am disturbed by the hook in the leech that was there from the start. The sailmaker said the hook is due to the cover, and there’s not much that can be done. Paint seems like a good option to ease the hook in the leech, and am considering getting rid of the sewn on cloth cover to keep the leech from getting wacked out of shape by the cover. My last genoa had a nasty leech hook from the cover, and ripped at the inboard seam where the cover is stitched onto the sail. I would like to take the cover off, and try the paint so I don’t ruin my $6000 genoa.

Did you try Plasti-Dip? Wonder if that might work. I used the Plasti-Dip (liquid with brush, not spray) as a mast boot sealer on top of stretch medical wrap (the stretchy ace-bandage type stuff) and it has been amazing over 2 seasons- not a drop leaks through, dry as a bone.

Hmm, interesting. Makes me wonder if we can paint our sails for decoration. My boat is a make that traditionally flies tanbark sails but when I inquired about replacing them I found that sailmakers charge about 50% more for tanbark, though I assume the labor to make them is roughly the same. Can I buy white sails and paint them to something resembling tanbark? Or, for that matter, could owners customize their boats by painting theirs sails with decorative colors or imagery?

I’ve applied Rust-oleum Outdoor Fabric spray paint to a roller furled polyester drifter with 2 oz cloth. This paint is intended to be used on lawn furniture cushions and lists UV resistance as one of its features. Application was easy, coverage good and the paint comes in a nice navy blue as well as other colors. It’s not heavy and does not impact the flying of this light sail. It’s expensive for spray paint at $11.95 a can and I needed 4 cans for the drifter with a 42′ leach and 30′ foot. After one summer, the paint seems in good condition, with no flaking or peeling. Time will tell if the sail is protected.

Seperate sail covers, that get pulled up on, say, a spinnaker halyard also deserve a mention in this article. This remains my preferred solution for furled sails.

Great idea. Was the paint applied only to the exposed side, like the sunbrella strip would be, or both to deal with bleed through? If both sides, were there any issues with it sticking to itself when furled?

Has anyone tried other inflatable boat top coat paints? Several other brands offer other color options, and I’m curious if they’re similar enough to the MDR product to be used instead.

Fred, this article references an earlier article on other inflatable top coat paints: https://www.practical-sailor.com/boat-maintenance/paints/a-peek-at-inflatable-dinghy-paint-test-panels-after-one-year

You never tried a silver coat primer and then a urethane flex agent in the paint. Aircraft fabric is a Dacron fabric on airplanes. The fabric vibrates and flexes continuously when flying. The painted surfaces are in the sun 24/7 and all last about ten years. I’ve been building planes as long as I’ve been sailing, about 60 years. Capt. Vince Rakstis, Ret.MS St.petersberg, Fl.

I wonder how Imron paint would work? The left over paint in the can seems to be the same material as super balls ,very bouncy, wonder if it would furl well.

I have had a weatherstrip on my Genoa for two years painted with Dulux Weathershield acrylic house paint in white So far no problems at all

I converted the old sail from hanks to a furler and could not justify the

Cost of putting on a fabric strip I am in New Zealand

Graeme, Very interested in your idea. Could you be a bit more specific on the type of Dulux Weathershield house paint that you used please? Did you use any primer/undercoat? Did you paint both sides of the sail? Any particular tips on applying the paint to a dacron/polyester sail? Many thanks, Tony (in UK)