Most times when I need a third hand, I can secure whatever I’m working on by jamming it in the groove between dock boards, or against a piling and placing a knee on it, or some combination. Work surfaces can incorporate cleats or holes for this purpose, but sometimes more specific clamping measures are required.

Clamp-on vices. Unless you have a very sturdy table to clamp this to, with an edge you don’t mind scarring, the larger sizes aren’t practical. We carried a small clamp-on vice on two boats for 20 years, and I can’t remember a single job where it was critically useful. A machinists vice must be through bolted to be of much use.

Drill Press Vise. Although more limited in terms of what they can hold, they have the major advantage of being useful without being bolted to anything. For drilling or filing small parts they can often be used without being secured at all. The disadvantages are that they are shallow, not as good for bending rods and strips, and less versatile when holding odd shapes.

C-Clamps and Vice Grips. The clamps can keep plywood work surfaces in place and prevent larger projects from moving. Vice grips are surprisingly versatile as a minimal vice, even better when a helper is available.

Portable Benches

An elevated work surface that avoids being bent over all day is be a blessing on larger projects. Add a clamping function and they can be darn handy for working on rudders, cabinetry, and larger parts.

Lazerette Topper

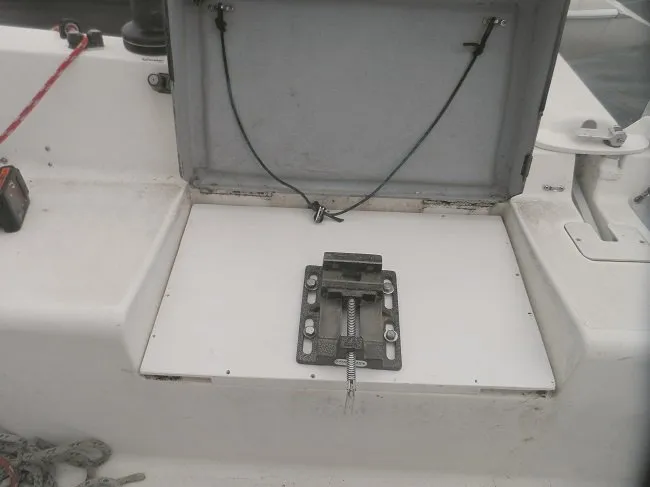

On my last two boats I built benches that fit across an open hatch, secured by the lip. It can’t scratch anything because it’s not sitting on anything, and an errant drill will penetrate nothing but air.

Measure the inside and outside dimensions of the lip when open. You fit -inch cleats (simple wood strips, not horned cleats) to the underside of 3/8-inch plywood board to prevent the board from sliding. These can bear on either the inside or outside of the lip, depending on the available space.

Toggles can be added to prevent lifting, but I never bothered with anything more complicated than a seated partner or my foot (a drill press vice applies minimal leverage to the bench). Tightly fitted, even that is unnecessary. The wood can be left unfinished to provide better grip, or painted to make for easier clean-up and reduce warping if stored in a damp place.

The drill press vice attaches using 3/8-inch bolts and T-nuts installed on the underside. A backing plate must be added where nuts are located, since the T-nut barrel is about 1.5 times the bolt diameter and may be thicker than the wood. Multiple holes and slots in the vice, and multiple T-nuts allow multiple vice positions and the use of several different vices.

Altogether it is a 20 minute project. Where does it store? Dangling by a string inside the same locker where it sits, ready for use when I need it.

Drew Frye is technical editor for Practical Sailor and author of Rigging Modern Anchors . He also blogs at his website www.blogspot.sail-delmarva.com.

nice touch. there are small clamp-on vises available, as stowable as the one pictured in the article. a review of variations on a grommet made tight by twisting it with a lever, that then secured, is worth some thought. quite adaptable.

So how do you exit the aft cabin in an emergency, like fire amidships with the escape hatch screwed shut?

Funny timing, as I literally attached the drill press vise to mine last night. Rather than strip cleats to keep the top in place, I used a 2nd piece of smaller plywood (2 x 3/8″) cut to the opening size of the lazaretto to create a 3/4″ thick work surface that had more mass and is a little stiffer. We’ll see how I measured when I take it down to the boat :^)

‘lazaretto’? love the Italian spell check

??

Ok, points;

Do you really need to mar up what you clamp a small vice onto?? Really? We can’t figure out a way to protect the surface?

Nitpickicking, but what is shown is not a lazArette. Hint: google it.

You can easily clamp a vice on companionway steps.

This Craftsman works really well (NLA) but one can find used ones.

https://de70d6fbd5219ded0a9f-95955c6a61a55e017c4c86a6d84cc235.ssl.cf1.rackcdn.com/525_624911.ct.800.800.jpg

Spelling is either optional, or a vice.