This report focuses on multihulls, because that is what we sail, but most of what we learned from this project can be applied to monohulls, as well. Our catamaran Josepheline is 38-feet with a 22.5-foot beam and draws 3.25 feet, weighing in at about 7 tons in full cruising mode. To put this into context our cat is the equivalent in windage to a 45-foot 13-ton monohull.

The current bridle system, as described below, can be modified to use on a monohull, where bridles are not common but could and should be used more often (see PS March 2016, “What is the Ideal Snubber Size?”).

Important note. You should never rely on the chain on the windlass to hold if your snubber fails. You need some form of chain-stop that isolates the windlass from load. We use a Dyneema strop attached to a strong point with a galvanized chain hook. We use the same hook and strop to secure the anchor (and chain) on passage. You can also use chain locks, Dyneema strops, or secure the chain using existing bow cleats. There are usually lots of options. Just don’t rely on the windlass.

Why a Bridle?

Bridles, as opposed to single-line snubbers, help to ‘share’ the load (see PS November 2013, “Anchor Snubber Shock Load Test”). This reduces the tension imposed on the securement point.

Nylon, the cordage commonly used for snubbers and bridles, has a finite lifespan, in part dictated by the load cycles. By sharing the load on two legs, you prolong the life of the rope. Sharing the load also helps reduce yawing, which can hinder holding (see PS February 2020, “Yawing and Anchor Holding”).

Our bridle arms are made of climbing rope, each 30 meters long with about 40-percent elasticity to breaking point. They quell chop, subdue yawing, and absorb large snatch loads. In our case, they do all this with a rode of 6mm G80

galvanized chain (see PS June 2016, “Pencil Thin Anchor Rode,”). The chain was treated with Armorgalv, a thermal diffusion galvanizing (TDG) treatment (see PS March 2015, “Armorgalv vs. Hot-dipped”).

The Chain Hook

We had looked at hooks, methods of attaching snubber-to-chain, and found many of them wanting. The best hooks undoubtedly come from the lifting industry where hook design is considerably more advanced than anything the marine industry offers. Lifting hooks are painted steel, powder-coated steel, or very expensive duplex stainless. We’ve not found a high-quality galvanized lifting hook.

It is possible to have an industrial lifting hook galvanized. We had a number treated with Armorgalv, but for most galvanizers, treating only a small hook is a nuisance—and you pay accordingly.

The problem with most hooks sold to the leisure marine industry is that they can stress the individual chain link or damage the galvanizing of the link to which they are attached.(see PS January 2017, “). Many of the devices designed to join a snubber to chain are not strong enough for the job. For example the ‘retaining’ pin on the popular Wichard hook is prone to bending, and once it is bent it can be hard to detach. Ketten and Waelder make a line of “Cromox” eye hooks and clevis hooks, but these duplex steel hooks are expensive.

Many people find success using Dyneema soft shackles to join the snubber and chain (see PS April 2015 “Going Soft on Shackles”), but we found them too fiddly to use on our 6 mm chain. (Even 8 mm chain can be too small to easily thread the Dyneema.) Link holes on imperial chains are bigger—and it maybe easier to insert a soft shackle. In our view, a chain hook is simple, effective, and quick to attach—even in the dark with a deck awash.

SHOCK ABSORPTION

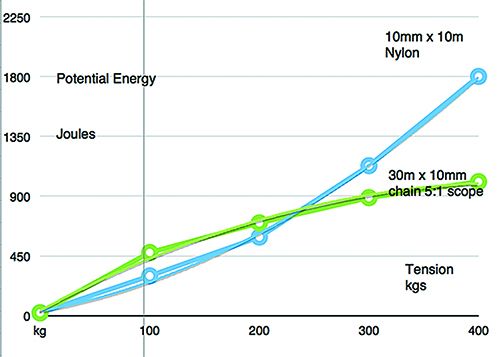

| JOULES | ||

|---|---|---|

| TENSION KG | 10mm x 10m Nylon | 10mm x 30m 5:1 scope chain |

| 100 KG | 300 | 475 |

| 200 KG | 590 | 700 |

| 300 KG | 1130 | 890 |

| 400 KG | 1800 | 1010 |

| 600 KG | 3440 | 1100 |

| 800 KG | 5460 | 1200 |

| 1000 KG | 7810 | 1250 |

about 1,000 joules. The nylon will continue to absorb energy beyond the 1,000 kilogram load until it breaks.

One of the incentives behind the development of a better snubber came when we switched from 8mm G30 chain to the 6 millimeter high-tensile, Armorgalv-treated G80 chain. Lightening the rode reduced our loaded weight, but it also meant less shock-absorbing catenary.

One of the easiest ways to add shock-absorbing capacity is to lengthen a snubber. With our demands of frugality we searched and found a climbing gym where we obtained some 30 meter lengths of used single dynamic climbing rope, which offers more stretch than conventional running rigging.

For safety reasons, climbing rope is routinely retired at relatively short intervals, when it is still perfectly suitable for less critical applications. Make sure you understand what you are getting, as not all climbing ropes share the same specs (see PS January 2016, “Testing a Dynamic Traveler”).

Running the Lines

The images and captions below illustrate the setup (see “Running the Lines on a Multihull Bridle”). Each bridle leg has a sewn loops at one end (see PS October 2014, “Stitching instead of Splicing”).

This eye is shackled to extra-reinforced pad eyes, which also serves as the chainplate for the prodder (bowsprit) bobstay. Each snubber leg leads through low-friction eyes in the chain hook (see adjacent photos), to a swivel-mount lead block on the bow.

From the turning block at the bow, each snubber leads aft through the struts in the stanchion bases. The snubber then passes through a clutch near the transom, then through a turning block on the transom (a spinnaker or screecher block is ideal), and then to a cockpit sheet winch. You don’t need a clutch. You could secure the snubber to cam cleat, a clam cleat, or even a horn cleat. The ‘spare’ end of the rope we stored as we would a sheet, in a bag hung from the lifelines.

Normally we simply deploy 15-20 meters. If the anchorage is exposed to chop or swell, it is easy to deploy more snubber. We leave our snubbers permanently attached at the bobstay chainplate. They are not obtrusive. With this new arrangement and extra length we can have about 15-20 meters of snubber in use on each leg. If the wind picks up—we can deploy the full 30 meters.

Prior to the new design, the hook would sit on the bottom when we were anchored in calm, shallow water. This could even cause the hook to disengage, something we observed with the first Mantus chain hook (see January 2014, “Mantus Upgrades Snubber Latch”). Reducing this excessive length was the final part of the puzzle.

In the new arrangement, with only five meters extending from the bow, the hook won’t sit on the bottom. Even if we terminated the line at the bow instead of running most of it aft, we’d still have the shock absorbing capacity of 10 meters on each leg, since it is doubled back.

Low Friction Rings to the Rescue

The key to creating a long snubber that wouldn’t sit on the bottom was our addition of low friction rings (LFR). LFRs are commonly attached with soft shackles or Dyneema strops but we wanted something that wouldn’t flop around. Snatch blocks would also work, but we chose to incorporate LFRs into the bridle plate.

We found two-part threaded LFRs used for fairleads through bulkheads, but they cost more than $100 plus per pair. To save money, we drew up plans for threaded LFRs and had them custom made in China. We ordered two sets, one set in a 6xxx alloy (magnesium and silicon) and another set in 316 stainless. The former would be used with redesigned bridle plate made of anodized 7075 aluminum alloy. The 316 eyes would be used in a bridle plate made of 2205 duplex stainless steel.

While we waited for our custom LFRs to arrive, we used stainless steel tubes to serve as a bearing surface on an ordinary clevis pin shackle. With one short tube inside the other, the pair of tubes were slid onto the shackle’s clevis pin like a crude roller bearing. This prototype gave us the chance to test the design and modify it as needed before we created the finished product.

With input from PS Tech Editor Drew Frye, Australian sailor and technical writer Jonathan Neeves deveoped a bridle plate specifically for use on his catamaran. Neeves finally settled on a version that met all his criteria for strength, quick attachment, and easy adjustment.

1. Bridle plate development : the original Frye/Neeves plate, a plate with claw incorporated, a 7075 plate home-anodized, a 7075 plate with gate, a four-snubber plate with a clumsy silicone gate. Bottom , profession-ally made 7075 plate, an untreated 7075 plate (with safety gate). An untreated Bis 80 plate with 316 two-part rings and, finally, the 2205 duplex alloy, black painted plate with 316 two-part thread rings with recess for gate.

2. To borrow from the design of modern lifting hooks a recess has been incorporated to seat and to spread to tension on the crown of the link. This was later improved with professional and skilled production.

3. Early in the project, Neeves Amorgalv-coated an industrial chain hook and added a safety lock. Industrial lift hooks also have locking devices, but they are prone to corrosion and can bend.

4. A custom-made bridle plate in 7075 alloy of aluminium and black hard anodizing compared to a ‘home made’ 7075 plate with low friction-ring inserts.

5. From left: Stainless steel twopart threaded rings, two-part aluminum rings, and standard low friction rings from Ronstan.

Since climbing rope cannot be spliced, sewn loops are used to form loops on the end of the bridle. A halyard knot will work, too.

2. The snubber arms for the bridle are routed through holes at the base of the stanchions. The arms are routed to a clutch, spinnaker turning block, and then to a sheet winch.

3. The bridles start at the waterline, follow a path through the bridle plate and then to turning blocks on the bow. In this man-ner, the plate develops a low location. This helps to improve scope because it automatically lowers the load’s focal point (the bridle hook) in relation to the water’s surface. Increasing scope, within reason, is almost always a good thing.

4. This photo shows the 2205 custom made duplex alloy plate with 316 stainless-steel, two-part threaded rings. Here it is rigged as it appears in use. The small shackle at the ‘front’ of the plate for securing the bridle while at sea.

V-Shaped Shock absorber

The system works surprisingly well. The vertical v-shaped portion of the bridle forward of the bow—between the bobstay chainplate to the turning block on the bow—creates an effective tensioner which noticeably cushions some of the movements generated from chop and swell. This works in the same way that a normal bridle (forming a horizontal V) helps reduce veering.

Additionally, the setup had the unexpected effect of reducing the angle of pull (increasing scope) under a snatch load. When a big wave lifts the boat and creates a sudden snatch load, the chain hook is pulled downward on the snubber. This significantly lowers the connecting point, which in turn reduces the angle of pull (angle between the anchor rode and the seabed). In deep water this makes little difference, but in shallower water the actual scope ratio improves noticeably.

This brings up another comment related to scope while using this bridle hook arrangement. For a more accurate picture of required scope, use the snubber hook height above water to determine the vertical factor in your calculations, not the deck level. Again, the difference is insignificant in deep water.

Normally we would deploy 20 meters of snubber, 10 meters up the side decks and 10 meters (two five-meter legs) beyond the bow.

If you expect the wind to pick up the best idea is to plan ahead and have a long enough ‘lazy’ loop of chain between bow roller and bridle plate. Then you can simply release more snubber using the sheet winches. You can do all this from the safety and comfort of the cockpit (in your pajamas if its 3 am).

If the lazy loop is too short you will need to venture to the bow, release the chain-stopper, deploy more chain, replace chain-stopper, retire to cockpit and deploy more snubber. We have found it is quite possible to release the snubbers ‘bare handed’ since the tension – at the cockpit – is surprisingly low. Using a sheet winch ensures anyone can do it. When you release extra snubber, the rope slips easily through the LFRs.

Better holding?

The location of the anchor, even without the roll bar, is fairly obvious from the

disturbed sand. Note how even the chain has buried so deeply it is not visible.

Another benefit of a stretchy bridle is a phenomena that has largely gone unreported, probably because you have to dive on the anchor to observe it. Without a bridle, and when all the chain has lifted off the seabed, we can feel the anchor noticeably twitching with every movement of the chain (and yacht).

In fact all the movements of the catamaran, yawing, horsing and vibration of the rigging is transmitted along the chain. To see for yourself how this works, wiggle a trowel in wet cement and watch the cement around the trowel refuse to consolidate. Leave the trowel alone and the cement will settle and “grab” the anchor.

This is exactly what happens as your chain rode is lifted off the seabed. This unwanted twitching increases in a short-scope situations. Arguably the lower shear strength of the seabed around the twitching fluke would help your anchor to set more deeply with shorter rode. This might be true, but only until the anchor meets an inconsistency in the seabed— trash, shell, or a buried kelp stalk. When that happens, you’ll begin to drag. In general, you don’t want the anchor moving about after it has set.

There are other ways of reducing twitching. For example, having a deep-setting anchor that buries chain will help. Buried chain reduces the vibrations along the chain to the anchor. Smaller diameter chain tends to bury more deeply (another reason we downsized).

Conclusion

We were so impressed with our new arrangement that we invested in two 30-meter lengths of new 12mm dynamic climbing rope with sewn loops at the end of each one (10mm would have also served well). The sewn loops attach to the waterline bobstay padeyes. We retired the ‘free’ ropes, which we now carry as spares or shore lines. Snubbers should be replaced with running rigging, or as soon as they show obvious signs of wear.

One advantage of having a free end to each bridle arm at the cockpit is that you can alter the orientation of the yacht, have one arm longer than the other, to suit conflicting wind, tide, or wave direction. This allows you to better balance the vessel and makes it considerably more comfortable at anchor.

One of the fears of long, elastic snubbers or bridles is that the yacht will yo-yo—surging fore and aft like a demented dinghy being towed in following seas. So far this has not, in any way, been our experience, and we have obviously been able to test it.

Our bridle development is very much a work in progress. We know we can improve the basic design of the plate itself. Some of the dimensions are obviously critical—the slot needs to fit the chain diameter, for example—but other important dimensions, like plate thickness to match the low friction rings, are not so obvious.

We also think casting the plate as one piece, all 2205 duplex and, possibly, polished, would be more sensible and attractive and will more easily allow incorporation of the developments of lifting hook designs. The whole system is thus a project in development. It works as it is, but it will be better!

The system can, relatively easily, be installed on a mono hull—in whole or in part. Most yachts have some form of fairlead at the bow or amidships and these, with judicious use of LFRs and short strops, can arrange a sensible ‘V’ for a horizontal bridle. Having a pad eye on the stem is obviously critical to accessing the advantageous ‘vertical’ component. A dedicated padeye could easily be installed—with careful use of reinforcing. If your boat has a bowsprit, you are probably already set.

Two thoughts: I wonder if having the entire plate machined from billet aluminum would be cost effective? LFR shapes and thickness could be incorporated in design. There certainly seem to be plenty of CNC machines about.

My other thought is to add Dyneema anti chafe sleeve over the climbing rope over the range of adjustment. If you stitch it in at both ends, the transitions would be smooth. I suppose the underlying rope could break down, and go undetected. I have good experience with double braids, but not climbing rope. I know climbing ropes are meant to be replaced frequently, and they may lack the longevity of sailing lines(?)

It is all a series of compromises – like much of anchoring and choice of ground tackle.

The intent was to make the plate ‘bullet’ proof and strong enough for use with G70 chain. This meant using 7075 aluminium alloy or 2205 duplex. Other aluminium alloys would simply not have the strength – unless you made the plate beefy. The aluminium would need to be anodised – and anodising would wear. For small components 2205 seems the answer. One option is to cast the whole thing in 316 or 2205 – this is being looked at (though there is the question mark of strength for the 316 – and that is not an acceptable compromise. However the plate is a work in progress – your suggestions are valid – and there are 2 x 7075 aluminium anodised plates being trialed (with 6xxx series 2 part threaded LFRs). The 7075 and 2205 plates are similar dimensions, CNC machined, but the 7075 plate ‘feels’ insubstantial and my wife ‘likes’ the substance of the duplex.

Climbing rope is designed with an abrasion resistant outer cover. But as you surmise it will wear. All snubbers should be considered as consumables we have broken 2 snubbers in 20 years – they fail with the sound like gunshot! – so your comment is very valid. Climbing rope is retired – usually as a result of a fall. Climbing rope in gyms is also retired to a timed schedule, or as a result of a fall. We carry spare climbing rope (which we can use as shore lines – if necessary). Once a pattern is established by an owner it would be a good idea to sleeve with dyneema – sleeves are easily sourced from most of the major cordage makers. If sewn – you would need to ‘bunch’ the dyneema up to allow for stretch.

You are on the right track for your comments. We have looked at a hybrid kermantle (‘climbing’) rope with the ‘elastic’ interior but a, loose, dyneema cover. The cover could be designed to control the allowable stretch. The rope maker we are working with believes it is all possible but we have not progressed the idea further – yet. (It all costs money!)

There is no suggestion the overall concept is perfect. As the system works the data has been released but it is a work in progress – nothing stands still and we would like to think it can be improved.

Jonathan

Great article and end product. Thank you. Unfortunately many of us do nit have tge engineering skills to design and fabricate our own. How do we implement the learning?

Mantus makes an awesome anchor snubber with or without the hook. Also Suncor Stainless makes an awesome hook to work with Mantus snubber.

Agree. Use Mantus snubber with their first generation hook and love it. No problem with hook falling off, no problems with twisting as swing 180 degrees in current.

And a lot cheaper than the Rube Goldbergesque idea presented here…technically what we have here is not “practical sailor”, but rather “impractical sailor”.

Thanks for sharing your experience! It’s worth mentioning that snubber and hook manufacturers have repeatedly modified their hook designs based on our research in this topic. Although the bridle and hook design, geared specifically to large catamarans, may be regarded as impractical for the average person to fabricate, the research is valid, the system (still in development, as indicated) is simple to use in practice, and the observations spur improvements among manufacturers. We wouldn’t be surprised if similar snubbers will be available to boaters. Dozens of improvements to name brand products (as well as recalls) have been generated by this type of PS research. As far as the title . . . Practical Sailor is an oxymoron to begin with, but after nearly 50 years, we’ve learned to live with it 🙂

My decade of single handing along the Pacific coast of Mexico gave me ample opportunities to experiment with all sorts of snubber and bridal attachments to anchor rode–both chain and rope. The solution I favored was to simply tie a barrel hitch around the rode. It was easily tied, adjusted, or untied and worked with most any kind of rope of smaller diameter than the rode rope or chain. In an emergency it can be easily cut with a minimal loss of line and no loss of hardware.

After using the barrel hitch, I gave away or tossed all the different hooks and shackles I previously used for this purpose.

K.I.S.S. I always say

Jonathon. Been reading your articles for along time with much interest. Really like the idea of high strength chain. Have you ever considered the idea of high strength galvanised steel wire? Flexible enough to run of a drum. To replace the chain.

I note that Skip Novak on his storm anchoring video uses a simple painted hook from the lifting industry. Hooks from the lifting industry are seldom galvanised and I assume Skip discards his hook, and replaces with a new one when rust becomes an issue. Lifting hooks are cheap and are designed not to damage the chain. If you look at many of ‘our’ hooks available in chandlers they have sharp edges which will damage the galvanising and point load the chain. The lifting industry would laugh at many of the hooks we use. The alternative is to team up with someone re-galvansing chain and add a couple of hooks from the lifting industry (with the paint stripped off) to the batch. One other option – speak to Spencer Industries (no connections), in New Jersey, they specialise in supply to the US military and galvanise, using the Armorgalv process, Hi Tensile steel components chain, hooks, hammerlocks, omega links, shackles as part of the assemblies used to tie down heavy vehicles on landing craft. They may have galvanised hooks available to you. Use the PS search facility to find out more about Armorgalv. We have all our ground tackle galvanised using the process completed in Australia. There are a number of Armorgalv operators in the US and a couple of other similar processes (Greencote??). The process caters for small HT items – check there may be one near you who might add a few units to a batch (offer to top up the coffee fund).

All the information is open source and Viking Anchors, no connections, have taken the design and made a similar bridle plate. We have never seen one in the flesh.

To offer snubbing the rope needs to offer elasticity under the conditions in which it will be used. This unfortunately means it is not going to have the strength of the rode. The life of a snubber is dictated by the number and size of the stretch cycles and if you focus on elasticity this does mean the life of the snubber will be finite (like your sails, and halyards) – but a snubber that does not stretch, and in strong winds it should stretch noticeably, not a few inches – is not snubbing. We have broken 2 snubbers, 3ply nylon, and we carry spare lengths of climbing rope (very useful as shore lines). We have not, yet, broken a climbing rope.

The advantage of the system described, commencing at the transom, is that if the winds look to become challenging, you can deploy more snubber, and you can winch in the snubber already deployed, add another snubber and then redeploy both.

If anyone has specific queries I am most happy to offer any help – simply contact me through PS by email – its all part of the PS service.

Jonathan

Good morning Chris, maybe evening where you are!

Yes and no! I have not considered wire because there are problems with joining the wire to anything else. I know you can use swages – but it needs professional equipment to have a good swage and with time this swages seem the weak link. We use 6mm chain, Armorgalv coated G80 and it has the strength of slightly less than 8mm G40 (there is an article in PS). Spencers, see my previous reply, have coated G120 (I believe with good result). Based on extrapolation of the tests conducted on small lengths of chain here in Australia it looks quite possible to coat a 6mm (1/4″) chain with the strength of a G30 10mm, (3/8th”) chain. One of the chain makers Rud or Pewag maker a high tensile 4mm chain.

These small chains behave a bit like wire, they are so thin, and I did think that maybe it could be retrieved on a drum winch. I spoke with a drum winch manufacturer and it would be possible (there are no gypsies for 4mm chain that I can find) – so there is a possibility.

BUT To test all this needs buying a new drum winch and having 4mm chain Armorgalv coated – and we have perfectly good 6mm chain with no signs we need to think of replacement.

So – its an idea waiting for someone who is like minded – I can do all the initial trials and testing – but I don’t want a new winch or chain, quite yet!

I might add – when you look at 6mm against 10mm the small chain looks like a toy – despite what the data says. You need to have confidence in the testing and suppress subjective fears!

Jonathan

If you are looking to have small intricate parts galvanised there are 3 processes of which we are aware, Armorgalv, Greencote and a third Impreglon (the latter slipped my memory :(. ). The process is generically called Thermal Diffusion Galvanising and we believe all 3 companies operate facilities in the US. We have used Armorgalv as it is the only operator in Australia. If you want advice before submitting parts check out the article in PS or contact me and I’ll do all I can to help. The process is geared up for small parts specifically high tensile parts, for example – nails for nail guns, shackles or 100m of HT chain!.

Jonathan

You guys do love to spend money ! There’s no need for al these hooks and other expensive devices. Learn to tie a prussic hitch. Use laid (twisted strands) nylon (springy) rope, 2 tons breaking strain minimum. Haul your chain in a little (judgement required !) and prussik the rope around a few chain links to spread the load. (Do it again on the other side for catamarans). Ease the chain until the prussik[s] is [are] just above water. Haul on the rope until the chain hangs in a moderate loop. Make the rope’s inboard end fast to something strong (judgement needed !). This setup held my heavy steel sloop in pounding waves when I was caught too close to a beach for comfort in a heavy gale in Brasil, which blew for nearly twelve hours. The snubber rope broke several times, I just replaced it. The anchors (two inline, none of that ‘Bahamian’ nonsense !) didn’t shift at all, even though the bow was going up and down through at least 6 metres. I’m still here to tell the tale !

We’ve done several reports on hitches and snubbers as you describe, and they have served sailors well for decades, if not centuries. Having had an experience similar to yours (except with Thai commercial shrimpers dragging down on me), I’d rather not relive that drama. Not having to go to the bow and risk lost digits or worse would have been a welcome relief. It will be interesting to follow Jonathan as the system gets truly tested. https://www.practical-sailor.com/blog/testing-sailing-knots-that-really-grip

I agree a lot with Rob Neal above. On our tri, 26ft wide, we have 45 ft of chain and the rest 3/4″ 3 strand nylon line. I use two 25 ft x 3/4″ nylon dock lines, drop the loop ends over the forward cleats on each bow and haul in enough scope and tie the other ends to the 3 strand with a taut line hitch (similar to the Prussik) and ease it all out until the bridles take the strain and the anchor line is a moderate loop. If I’m in shallower water and want the chain further off the bottom (coral etc.), I tie snap hooks on the lower ends and snap them onto the chain. Haven’t tried tieing them to the chain. Probably would work fine. Any adjustment needed for offset angles etc., can be made at the bow cleats. All works very well with no manufacturing involved.