A definite correlation exists between the degree to which we are warm and dry, and the enjoyment of a sail, or a night at anchor. A damp and chilly environment may be exacerbated by a poorly insulated hull, leaks, and sweating. Sitting beneath a drippy port or headliner, or curling up in a damp bunk, just isn’t fun.

Your boat can be matched to a heating system that, at one end of the spectrum, will simply prevent the formation of icicles or, at the other, provide a space as warm as that den at home. Sources range from electric “cubes” and oil-filled radiators plugged in dockside, to hanging lamps, to the nautical equivalent of central heating. Cost ranges from almost nothing to the limits of your credit card, notwithstanding the recapture of part of the initial cost when the boat is sold.

We last covered this topic in the September 1997 issue. While many of the options remain the same, there have been a few new twists in the intervening six years. So here’s the updated overview.

Health Issues and Background

There are two related dangers in heating a boat with any kind of fossil-based fuel. The first is the chance of producing and/or concentrating carbon monoxide in the living spaces. As we know, CO will kill us straightaway. The second is complacency in assuming that we have the CO angle covered adequately. The more the brain is deprived of oxygen, the less able it is to understand what’s happening to it. So, proper ventilation of living spaces aboard a heated boat, no matter what type of system is used, no matter whether it’s vented outboard or via portholes and companionway, is absolutely vital.

Heat for a physical space is typically measured and reported in British Thermal Units, or Btu. (Heat produced by the energy of the human body is measured in calories.) A Btu is the amount of heat energy required to raise the temperature of 1 pound of water 1 Fahrenheit. Determining what type of heater is best for you involves considering the characteristics of fuels (see accompanying table), the hardware options to run it; where the hardware will be on board; how to strike a balance between insulation and ventilation; your own tolerance of (if not liking for) cold temperatures; and the weather in which you plan to be afloat.

Fuel Types

Small electric heaters are handy for taking the chill off a boat in the morning, evaporating dew that may accumulate on the overhead when bodies sleep below, or on a chilly evening.

When your cold-weather travels extend beyond the marina, however, so do the requirements for a different system. Beyond the output of the heating system, a primary consideration is the capacity to carry fuel for the duration of a voyage, and the availability of fuel in destination ports. Generally, towing a barge loaded with crude oil is not a viable option. Thus, choices become diesel, kerosene, propane (LPG), natural gas (CNG), wood, coal, pellet fuel, alcohol, or charcoal. Of the options, diesel and kerosene are the most readily available. Propane is also easy to find. CNG is not. Good stove alcohol is available in chandleries, and is convenient if you’re already running an alcohol stove-but it’s not the fuel of choice for serious systems.

In temperate climes, a simple oil or kerosene lamp will take the edge off the chill well into autumn. Using deodorized kerosene eliminates the odor of the fuel. However, an excess of fuel produces smoke, ruins the wick, and creates a housekeeping chore. Since kerosene produces four gallons of water vapor per gallon of fuel, not an insignificant amount, lamps require good venting, and quite a bit of heat goes out the window, literally. They are, however, romantic.

How to determine how much heat you need? One method is to determine the average of the water and outdoor temperatures during the coldest months. Then, assume that 700 cubic feet of interior volume requires 3,000 Btu to maintain a temperature 25 higher than that average. However, there really are too many variables involved to put much stock in a formula like that. Boats, people, and locales all differ far too much, and what’s comfortable enough for one person will be misery for another.

Again, for many who spend an occasional day or night aboard in chilly weather, simple oil lamps, bolstered by a good fleece pullover and warm shoes, will often suffice. One of us, for example, heated the main cabin of a Hans Christian 34 while anchored at several Pacific Coast harbors from early fall until mid-winter with an Aladdin lamp suspended overhead. But many people wouldn’t have been comfortable in that cabin. Another lived aboard at City Island, NY, completely frozen in one winter for over a month, with temperatures never rising above about 20 F. In those temperatures, the oil-filled electric radiator couldn’t begin to keep up. That was a winter when most of the liveaboards gathered daily to splice the main brace aboard a Whitby 42 with diesel heat.

In order to get truly adjustable comfort, or to equip a boat to stand up against serious elements, a fixed system will be required. We could then divide those systems into two subsets-ones that carry heat around the boat by means of pipes or ducting, (e.g. that Whitby) and those with a strong central heat source (e.g. a fireplace) and fans to move the air into the far reaches of the boat.

Moving the Heat

Nothing is more efficient than radiant heat produced by the sun, or a heat source that directly affects the area to which it is exposed. However, while sitting in direct sunlight on a cold or damp deck, your nose may be toasty while moss grows on your posterior.

The same is true belowdecks. Few boats are well-insulated, and whatever warmth is developed below on a cold night tends to be exchanged at a fast rate for the chilly stuff.

Here’s a scenario that will be familiar to many: The air temperature in the harbor is 40 F. and there’s a wet wind blowing at 12 knots. The water temperature is 46 F. You’re sitting in the main cabin right next to your main heat source (a wood stove, an electric radiator, whatever). Your head and torso are hot. Your hands are warm. Your feet are cold. The forepeak is cold. The aft cabin is cold. The head is cold. You lean outboard and put your feet up. Within a minute, your head is cold and your feet are hot.

You may have an excellent source of heat and a lot of Btus, but this is what life will generally be like in cold weather if you have no method to circulate warm air into occupied spaces efficiently. Options include units mounted on bulkheads that rely on fans; ducted systems with outlets in living and sleeping quarters; and heat produced by the circulation of warm fluids to a heat exchanger.

Small Electric Heaters

There are dozens of these on the market, so we’ll just mention a few. This type of heater is most appropriate for the heating of small spaces, or replacing a light bulb that once served as a boat dehumidifier during winter months. The simplest solution is a portable unit equipped with a fan. Add a thermostat and the heater may be left running during winter months to prevent the formation of frost belowdecks, and may prevent the accumulation of ice on the deck. We had good luck heating a 36-foot race boat in San Francisco and the Pacific Northwest using this method.

Caframo’s Turbo Heater, and its lookalikes, are traditional electric heaters. The newest Caframo units have separate switches that control temperature and fan speed, though designating heat output is measured on a scale of 1-4, rather than by a thermostat. A new wrinkle is an “anti- freeze setting” that automatically activates the unit when the temperature reaches 38 F. A disadvantage of these units is that they blow heat in only one direction. Suggested retail is typically $60-70.

We found the Holmes One-Touch ($99 on sale) at a hardware store. Not exactly a household name, knockoffs are marketed under several brand names. This electric unit is equipped with a two-speed fan, has fixed and oscillating capacities, and temperature settings between 60-80 F in 5- degree increments. It’s an excellent alternative to the fixed unit.

It is unlikely you’ll find the Back Seat Plus (model 3000) manufactured by ThermTech in a chandlery, since it’s primary use is as a back seat heater for vans and sports ‘utes. Nonetheless, this 12-volt unit, which is equipped with a quartz heat cell, produces 1,100 Btu and is thermostatically controlled. It will be handy when heating smaller spaces, like the V- berth on a 25-footer, when connected to a long wire harness.

Equipped with a swivel bracket, it can be mounted where heat is needed, and is only 5″ x 7.75″ x 8.25″. Suggested retail price is $150.

Alcohol Heaters

The Origo Heat Pal is an alcohol-fueled heater that has been on the market for a long time in various models, and Origo has become the company most closely associated with alcohol cooking and heating in the marine world. This heater isn’t very sophisticated-it just provides a relatively safe place to burn the fuel. It need not be permanently mounted, and would serve well for the occasional warming effort, especially if your primary stove fuel is alcohol. Just remember to ventilate well, expect some condensation, and buy the best alcohol you can find, to reduce odor. Despite its wide base, we’d be reluctant to use it underway. Retail price is $147.

Cook Stoves and Fans

Unless you’re desperate to prevent the formation of icicles on the headliner, a cookstove should not be used as a source of heat. An open flame is not particularly effective and creates a fire hazard. We should mention, however, that many people over the years have reported success in warming cabins by upending ceramic flower pots (vented) over a burner flame set on low. Again, much depends on how you circulate the resulting heat.

If you’re considering this method, have a look at the Wallas Safeflame 800+210 and 125 DP/DU, which offer no-flame operation and convert a stove to a forced-air heater by lowering a lid that becomes a ceramic surface. These units are most common in the gallies of small powerboats. As heaters, they are pricey; as an option for a combined stove and heater, less so, and compact. The kerosene-fueled 800+210 unit develops 4,000 Btu at a cost of $875; the 125 DP/DU, which is diesel-powered, 6,000 Btu at $1,350.

Solid Fuel Stoves

Beyond their functionality, these units usually make lovely additions to a wood-paneled saloon. They may be fueled by wood, coal, charcoal, or pellet fuel, but the downside is that they don’t fuel themselves. Therefore, the trade-off for a small combustion chamber is likely to be a few stoking sessions in the middle of the night.

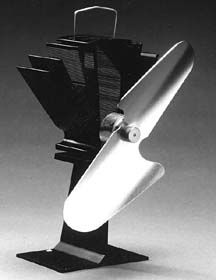

While free-standing models exist, these stoves should be mounted on a bulkhead, and they’re more efficient when equipped with a fan.

Installation involves placement of a stovepipe/chimney, usually 3″ in diameter, for proper ventilation. The pipe, and the weatherproof cap atop it abovedecks, are called a Charlie Noble. Though Charlie may be a shiny accent piece, he also can burn gear or canvas left close to his cap.

These stoves require a high degree of maintenance, since the buildup of tar and soot in the stovepipe are a by-product of the fuel used.

The Paul E. Luke company’s tile fireplaces have fireboxes fabricated from plate, which reduces the potential for leakage at square-cut joints. An option is an LPG burner with an automatic shut-offactivated when the flame is extinguished.

However, Frank Luke says, “The most popular versions are still thesolid-fuel units. We currently have some uncommonly beautiful Virginia soapstone which has a nice fine grain and interesting marbling. The most popular models are the polished brass units. They need to be polished regularly, so my father said ‘that’s the other way they keep you warm.'”

Prices for 24″ tall units range from $1,549 for Soapstone to $1,795 for solid brass or stainless steel.

Liquid Fuel Fireplaces

The alternatives to solid-fueled units are fueled by kerosene, diesel, or LPG. Most use a drip form of burner, and fuel flow is regulated by a needle valve. Plumbing a unit from the boat’s fuel tank simplifies storage. Force 10 and Dickinson Marine share the majority of the market here.

Dickinsons Newport P9000, the most traditional model, is fueled by diesel or kerosene and produces 3,100 -4300 Btu. A recent upgrade for sailboats adds the option to convert to propane with a unit that may be mounted higher on a bulkhead than older models. A built-in blower fan directs air downward to maximize circulation. Turn on the fan and the range increases from 5,500 to 7,500 Btu. The company recently added the model P12000, which has output ranging from 4,000 to 9, 700 Btu. Some models are equipped with an electric spark ignition and automatic gas flow shut-off to prevent the flow of fuel if the flame is extinguished; some are available with thermostats, others with a forced-air blower.

Depending upon fuel type, the P9000 retails for $691-$710; the P12000 for $796. A solid-fuel unit retails for $344.

Force 10 also offers liquid-fueled units with automatic starting. These automatically shut off when the oxygen content of the cabin drops below 95% of normal, a real plus.

The company’s Direct Vent Cabin Heater (model 13000) outputs 4,000-9,000 Btu using propane; it is priced at $840. The Model 10000 Cozy Cabin Heater is a smaller version, also powered by propane, that produces 6,000 Btu, weighs only 11 pounds, and retails for $480. A near twin, the model 10004 is fueled by diesel or kerosene, with the same Btu rating. It requires a pressurized fuel source (like a bicycle pump) and must be preheated with alcohol before use-both inconveniences. Suggested retail is $415.

The only shortcoming of this type of unit is that it lacks the circulatory ability to prevent big fluctuations in temperature from cabin to cabin.

Since both companies are bastions of the industry, and their current products the result of an evolutionary process, choosing between the two may be a function of evaluating the space in which the unit will be installed, cost per Btu, and appearance.

Forced Air and Water Systems

In operation, these bear a striking resemblance to the units used in houses. A typical unit is fitted with an electrically powered fuel pump, flame ignition device, forced draft combustion chamber and heat exchanger, fuel metering pump, and integrated control unit. Hot air is circulated via flex tubes to vents, generally in the saloon and staterooms. The effectiveness of the systems is determined by the power of the heater, and distance to vents. The newest units on the marketplace take up surprisingly little space, are easily mounted, and may be coupled to an existing fuel source. Their greatest disadvantages are initial cost and the amount of space they take up.

Picking the right unit involves a critical evaluation of the boat’s power system to compare the amount of additional electricity necessary to operate a heater’s fuel pump and blower to existing demands for energy.

The market is dominated by Espar, Webasto, Ardic, and Wallas-European companies represented by American distributors. Of the group, only Wallas and Ardic manufacture heaters designed specifically for the marine industry. Espar, for instance, enjoys great acceptance in the marine market, though 60% of the company’s business is in the trucking industry.

Since our last review, Espar’s new generation of forced-air heaters are 21% lighter, and smaller, and have 40% fewer parts. The models heretofore most commonly found on sailboats, the D1LC compact air heater and D3LC, have been replaced by the Airtronic D2 Air Heater, which produces 2,000 Btu to 7,500 Btu in “boost” mode, and the Airtronic D4, which doubles the Btu output. The D2 weighs only 6 pounds; the DS 9.9 pounds.

Webasto also introduced several new models since our last review. The Air Top Series is designed for use in boats 28 feet and larger, and produces 2,000-18,000 Btu. New features are the elimination of glow plugs, more efficient combustion chambers, reduced noise, and built-in diagnostics program.

The AT3500 ($1,555), designed for use with 28-34 foot boats, includes a central thermostat with automatic shutoff. Heat runs are through 24 mm flexible tubing. Total runs should not exceed 30 feet.

The newest Wallas models are the 30D and 40D Nautic forced-air diesel heaters, which produce from 2,700 to 14,000 Btu. Both are compact, weighing only 20-22 pounds, and requiring 12″ of vertical height, plus plumbing, and consuming 1/4-1/2 gallon of fuel per hour. Improvements are a cleaner burning combustion system; the small unit has a thermostat, the larger an adjustable heat range with optional thermostat. The 30D is priced at $1,850; the 40D at $2,150.

Though seen less often on sailboats, an option to circulating warm air is a system that circulates heated fluids to heat exchangers. Heated fluid is transferred from a combustion chamber through a sealed loop routed to various parts of the vessel. At each location, a heat exchanger equipped with a small blower provides a flow of heated air. This type of installation is often easier on a smaller boat than finding room for an air duct.

In addition to Btu, a key measurement is the rate at which water flows through the boat, called “water throughput,” which is measured in gallons per hour. A second measurement is fuel consumption, compared to alternative heating methods.

In addition to producing clean heat, these systems generally offer two additional advantages: hot water from the heater can be plumbed into the heat exchanger of an existing hot water heater, thus also producing hot water for galley and head. In cold climes, the hot water may be used to heat the boat’s engine block, easing starting and reducing the draw on batteries.

Espar’s Hydronic line of coolant heaters have outputs ranging from 5,500 Btu to 120,000 Btu, which might be adequate to heat the Endeavour. An advantage is that all of the components, excepting external plumbing, are essentially self-contained, and have 2 to 4 cycle levels to maintain a constant water temperature. The Hydronic D4, for example, which may be powered by diesel or kerosene, produces 13,700 Btu in boost mode, and circulates 132 gallons per hour. The Wallas Ardic 952-DW produces 16,000 Btu in passive mode, which doubles when the engine is running. But heat comes at a price: a system with a diesel- fueled heater with water and fuel pump, control unit, and three-speed blower costs $2,650.

Conclusions

It is impossible to measure the cost of being uncomfortable in dollars, but it is possible to measure the cost of a heater system. First, determine the cost of the heater unit/combustion chamber. Add the cost of piping, ducting, heat exchangers, wiring, Mr. Noble, and the like. Then add the cost of installation. Even if you’re capable of installing the heater, we recommend hiring an expert who will help evaluate your boat’s requirements, develop an installation plan, and provide a list of required tools. When the project is completed, the technician should examine the system before first use.

Also With This Article

Click here to view “Fuel Characteristics.”

Click here to view “What Installers Say About Heating Systems.”

Click here to view “Specifications: Selected Heaters.”

Contacts

Ardic, Wallas, 888/606-6665; www.scanmarineusa.com.

Caframo, 800/223-7266; www.caframo.com.

Dickinson Marine, 800/659-9768; www.dickinsonmarine.com.

Espar Heater Systems, 800/387-4800; www.espar.com.

Force 10 Marine, 800/663-8515; www.force10.com.

Paul E. Luke, 207/633-4971; www.peluke.com.

Origo, 941/355-4488; www.origo-sweden.com.

Therm-Tech, 616/530-6540; www.therm-tech.com.

Webasto/Sure Marine Service, 800/562-7797; www.suremarine.com.

Having trouble with my steering it is a hydraulic steering which has been blead I am thinking my brother maybe too small for the size of the boat I have a 36 foot Taiwanese troll can anybody advise

See if you have a small seal or line leak. I have had my ram and healm rebuilt and it fixed my problem.

I want to share my experience with a thermostat controlled oil filled radiant electric heater. It performed flawlessly on board for the entirety of 3 or 4 years while in marinas on the NW Pacific coast, preventing mildew and fungal growth during winter with no one aboard and for comfort at other times of the year when people were on board. However, one night while I was on board, I was awoken by a very acrid odor and found the cabin filled with dense smoke. After escaping to the cockpit to get air, I went back down into the main cabin, turned on the overhead lights and found the odor and smoke coming from the heater. The electric power cord to the heater was not hot and no circuit breaker had been triggered. In the morning I found that a small area of the metal jacket had rusted through, allowing ambient air to mix with the oil where the heat electrode makes contact with the passive circulation of the oil. Judging by the smoke and the odor, I think it was very near the point of combustion and quite likely would have started the boat on fire, or at the very least could have resulted in my death by asphyxiation, had I not awoken in time. My thoughts on how this happened is that in a cool humid salty air environment, each time the thermostat prompts the unit to turn off, the salty humidity in the ambient air begins to cool, allowing salt water vapor to condense onto the metal surface of the heater until the thermostat turns the heater back on. But each time it heats back up, it leaves a thin film of crusted salt that attracts moisture and this process leaves more and more salt deposit by repetition, over and over again. So, my opinion on preventing this from occurring to anyone else is that this type of heater used on a boat, particularly where exposed to salty air, should be routinely inspected for rust and wiped down with a clean cloth dampened with fresh water. And, even without visible rust, the unit should be removed from service on the boat after a period of two years on board, whether used continuously or not. For improved safety I now use an electric dehumidifier, setting the humidistat to turn on at aprox 40% relative humidity. The unit has a fan that circulates cabin air at about 75 degrees F and produces condensed water that drains from the unit via a hose into the sink which has the only thru-hull valve on the boat that I leave open and the double all-stainless hose clamps get inspected for rust before leaving the boat unattended for the winter.

Steve, sounds like a thin wall on the heater or a defective product. I have used these same heater onboard for years and in the house. They are inspected regularly and have had no problems other than replacing a rocker switch.

Great article, hope I won`t need heat much longer.