Batteries and solar panels can be a black box. We can’t see or hear or feel what is going on inside. They’re not complicated at the level a sailor needs to understand them, but looking at a panel ammeter or even a battery monitoring system won’t give you the simple, certain information you need: Is it time to replace my battery or solar panel?

Battery capacity for a 12V deep cycle battery is measured in Ah and indicated on the battery. Batteries lose capacity as they age. There is no sure way of knowing how much longer the battery will last, but barring a sudden internal failure, knowing lost capacity can give you some idea of life expectancy.

Solar panels are rated by output in watts (amps x volts), and we generally measure their health by monitoring output in amps and volts. The problem with relying solely on an ammeter or voltmeter to determine panel condition is that these instruments don’t account for some variables or adjust for others. For example, resistance from the cabling and battery bank, sun angle, clouds, shading, and charge controller behaviors can all skew output readings.

To truly compare battery and solar panel performance to their original ratings, they should be tested in isolation using methods that can approximate standard conditions.

DETERMINING SOLAR OUTPUT

Using the solar panel controller’s amp readings is problematic because this doesn’t account for sun angle, shading, and resistance in the system’s other components, including wires and batteries. The charge controller’s amp reading tells you that the system is working, and it gives some idea of how much power is going back into the battery. However, to obtain the actual power output that we can compare to the factory rating, we need to collect some data and use a little math.

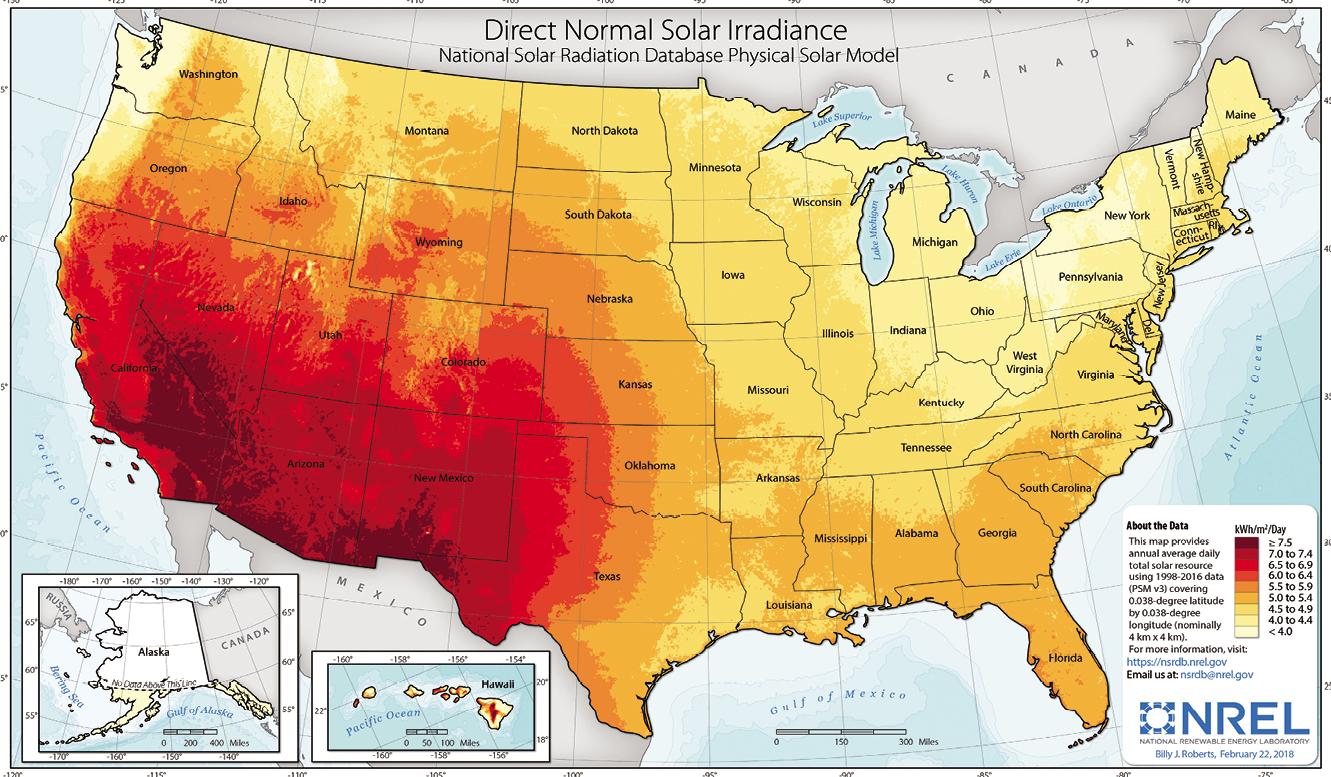

The solar radiation basis for rating a solar panel is 1 kilowatt-hour per square meter (KWh/m2). This is very close to the radiation hitting a solar panel exposed to direct sunlight in the desert Southwest. A typical rule of thumb for determining daily output is to multiply the rating times five hours. This allows for variations in sun angle, the number of daylight hours, and cloud cover.

This five-hour basis yields a conservative estimate of usable output in the mid-latitudes in early and late summer, and is sufficient to decide how many panels we need. The panels might exceed this estimate on a clear mid-summer day in the south, but in the fall or farther north, the five-hour estimated output, or even less, may be more realistic. And that is before we factor in shading and bird bombs (when was the last time you cleaned your solar panels?).

TESTING SOLAR PANELS

Like batteries, solar panels decline with age. Glass-covered panels can last 15-20 years, after which the output will be reduced by 30 percent or more and they should be replaced. Semi-flexible panels age much faster and will seldom be effective after 10 years. Flexing causes micro-cracks in the cells and the plastic cover sheet becomes cloudy (see “Solar Panel Self-Destruction,” PS September 2021).

SOLAR PANEL ASSESSMENT

Here’s how you can determine whether your old solar panel is still delivering its rated output.

To check your panel, you’ll need a few tools: a multimeter to measure voltage (meters from Gardner Bender and Fluke fared well in our testing, see “Digital Multimeters,” April 2004), a clamp-on DC ammeter (Klein CL120, $55 is an economical choice), a DIY resistance device (a car 12-volt headlamp of known wattage) or an electronic adjustable intelligent resistance tester, sometimes called a constant current tester (MakerHawk has $50 tester rated for 150W-200V-20A; www.makerhawk.com). You’ll also need a thermometer to measure the panel’s surface temperature (the Klein IR1 infrared thermometer works well). These tools will help troubleshoot electrical problems at home and on the boat, making them well worth the initial investment.

1. Pick a clear day where you can see 20 miles easily. Any haze or overcast will invalidate the test. Eliminate all shading. There is no simple, accurate way to correct for even a small shadow.

2. Clean the panels. Do not compound or buff plastic semi-flexible panels; a gentle waxing is okay.

3. If practical, place the panels at 90 degrees to sun. If not, use correction Table B.

4. Attach a known load that is close to the panel rating. This is where your 12-volt car headlamp, or constant current tester come in handy.

5. Use your multimeter to record volts and amps (amps x volts = watts). Try to hit the specified maximum power point (MPP is usually 17 volts); anywhere between 12V and 17V is usable.

6. If your voltage reading is not at the maker’s specified maximum power point, divide the amps from step 5 by percentage of output that is indicated in Table C.

7. Use an almanac, celestial calculator, or the internet (www.gml.noaa.gov/grad/solcalc/azel.html) and Table B to determine the total sun angle on your day of testing.

8. Compensate the total amps in Step 7 for temperature. Solar panels are rated at a surface temperature of 77F. For each degree Fahrenheit above 77F, the panel’s output will be reduced by 0.143%.

9. Multiply your adjusted total amps from step 8 by the manufacturer’s MPP (usually 17V), this will more closely approximate the actual panel capacity in watts as it would be rated under standard test conditions. With this figure in hand, you can now compare it to your panel’s specs to see how much efficiency has been lost over the years.

AN EXAMPLE PROBLEM

This can seem a little confusing, so let’s walk through an example evaluation of an aging solar panel rated at 200 watts at its 17-volt maximum power point (MPP).

1. Record output. After confirming we’ve followed the instructions regarding the test setup (clear sky, direct sun, connected to meters, constant load, etc.), we use our meters to check output. It shows an output of 10 amps at 12 volts or just 120 watts (10A x 12V = 120W).

2. Adjust for voltage output. Since the voltage is 12V, not the panel’s rated panel’s MPP (17V), we refer to Table C to find the corresponding output correction.

Approximating from the table, the correction for 12V is 84.5 percent. To make the correction, we divide our output from step one (10A) by .845 (84.5 percent) to get a standardized output: 10/0.845 = 11.83A. Rounding to the nearest tenth, our

voltage-adjusted output is approximately 11.8A.

3. Adjust for sun angle. We refer to NOAA’s online calculator or (an almanac) and Table B to determine total sun angle at time of our test. NOAA says the sun angle (elevation) is 60 degrees. Per Table B, the total sun angle correction is 78 percent. We divide our adjusted output from Step 2 (11.8A) by .78 (78 percent) to correct for total sun angle: 11.8/0.78=15.1A. Our adjusted output is now 15.1A.

4. Correct for temperature. Each degree above 77F reduces output by .143 percent. At our panel temperature of 107F, the loss is 4.29%: (107-77)0.143=4.29. This means the panel is 95.71% efficient at that temperature: (100-4.26)=95.71%. We’ll divide our adjusted output from Step 3 (15.1A) by this percent to get a value that correlates with the rated (77F) output: 15.1/(95.71/100) = 16.3A. So, our temperature-adjusted output is 15.8A.

5. Calculating watts. Multiplying amps from Step 4 (15.8A) by the measured voltage (12V) gives us a corrected output in watts (W): 15.8A x 12V = 189W.

6. Findings. As it turns out, our 200W panel is putting out a respectable 189W. Without the corrections, we might have thought the output was just 120W (10A x 12V = 120W) and rushed out to buy a new panel.

CONCLUSION

It never hurts to install about 20-30 percent excess capacity in batteries and solar panels. Loss in panel efficiency and battery capacity varies with conditions and is inevitable. Having more power and capacity than you need will help them remain useful well into old age. Accurately measuring storage and charging capacity will help you better understand your energy needs, troubleshoot your system, and avoid unnecessary expenses.

TECH GUIDE: TOTAL SUN ANGLE CORRECTION FACTORS

| SUN ANGLE | PROJECTED AREA CORRECTION | ATMOSPHERIC CORRECTION FACTOR | REFLECTOR CORRECTION | TOTAL ANGLE CORRECTION |

|---|---|---|---|---|

| 30 degrees | 50 percent | 71 percent | 82 percent | 29 percent |

| 40 degrees | 65 percent | 81 percent | 88 percent | 46 percent |

| 50 degrees | 77 percent | 89 percent | 92 percent | 63 percent |

| 60 degrees | 87 percent | 95 percent | 94 percent | 78 percent |

| 70 degrees | 94 percent | 100 percent | 95 percent | 89 percent |

| 80 degrees | 99 percent | 103 percent | 96 percent | 97 percent |

| 90 degrees | 100 percent | 104 percent | 96 percent | 100 percent |

TECH GUIDE: MPP CORRECTION

| VOLTS | PERCENTAGE OF MAXIMUM POWER POINT (MPP) |

|---|---|

| 10 volts | 71.3 percent |

| 11 volts | 77.9 percent |

| 12 volts | 84.5 percent |

| 13 volts | 88.8 percent |

| 14 volts | 93.3 percent |

| 15 volts | 97.2 percent |

| 16 volt | 100.0 percent |

| 17 volts | 100.0 percent |

| 18 volts | 97.5 percent |

| 19 volts | 91.0 percent |

| 20 volts | 80.7 percent |

Leaving us just one small problem to fix before we set sail.

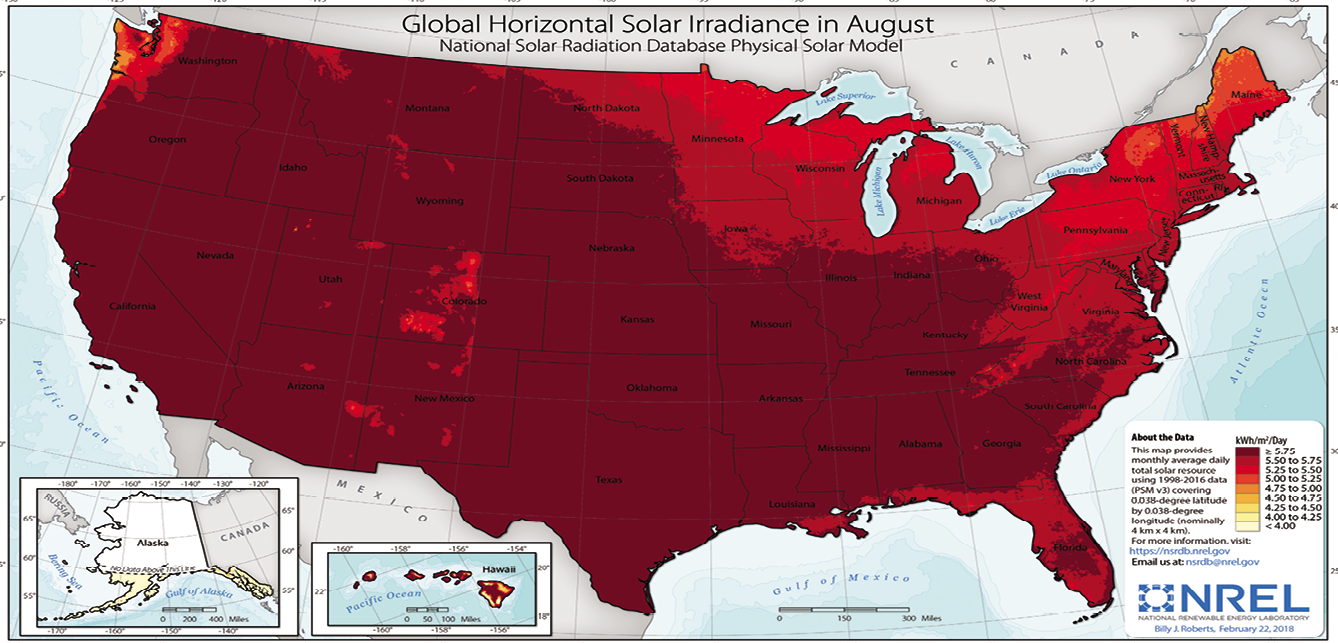

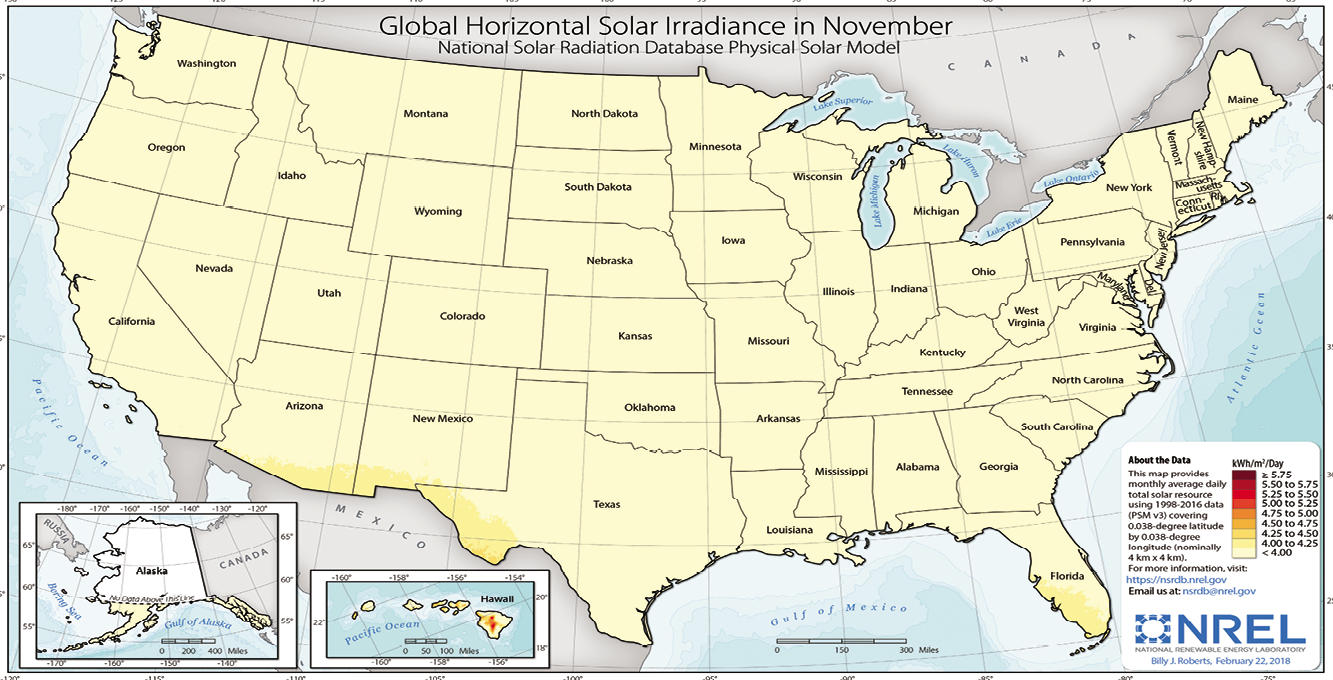

1. At first glance most coastal areas in the U.S. have the potential to generate about 5kWh per square meter of solar panel per day.

2. August is prime time for solar panels in U.S. coastal waters, despite summer rains.

3. By October, solar potential is down by 20 percent in the sunniest places where you can float a boat, and more than 60 percent in others.

Not a comment, a question. And forgive me for asking it here, but I can’t think of any place else TO ask it.

I’ve just bought a new (to me) boat, and the batteries are in an extremely extremely awkward location. My previous routine of flashlight and turkey baster just isn’t going to fly; just getting the caps off will be a pain.

I have a (dim) memory of reading a short review in PS of battery electrolyte filling devices .. both the watering jugs style as well as the leave in place caps.

Sadly, I cannot find the article! I would think it was recent .. my failing old man memory doesn’t go too far back. (What I had for breakfast is fuzzy .. and it’s still morning!)

But I’ve paged through five years of issues without finding it. And online searches of the PS archive has turned up nothing.

Is this just a hopeful figment of my imagination? Or can someone point me to the issue?

Thanks in advance for any help and again, my apologies for this inappropriate bandwidth use.

Alan, Here is an update to our battery filler article. I believe most of these systems are still available. You can reach me directly at [email protected]

Darrell

https://www.practical-sailor.com/systems-propulsion/ensuring-a-safe-space-for-batteries