The Atlantic Hurricane Season is off to a slow start this year, but we can expect activity to pick up in the months ahead as Atlantic basin temperatures reach record highs. Experts say the subdued activity thus is in part due to the beginning of the El Nino cycle, which can suppress storm formation in the Atlantic. The impact will depend upon the intensity and duration of this El Nino cycle, and NOAA recently deployed autonomous sailing drones to the Pacific to get a clearer picture of water and atmospheric conditions at sea level.

If you lie in the hurricane belt, and haven’t given storm preparation a thought yet, a good start would be our report, Lines, Snubbers, and Other Gear for Battening Down Ahead of Storms. Safety expert Ralph Naranjo’s first-hand account of his storm preparations Tropical Storm Do’s and Dont’s and How to Help Your Boat Survive A Major Storm should also be required reading. These articles all discuss the first line of defense against a hurricane: secure your boat in a boatyard or hurricane hole.

But what if you have no option but to stay on a municipal mooring? Will these hold? Although we’ve never put much faith in mooring systems that we didn’t have a hand in designing and installing, there are some mooring systems that deserve a closer look.

One class of product that has been gaining more attention in the wake of Hurricane Irma is the elastic mooring systems being used in Florida’s municipal mooring fields as well as throughout the Caribbean. Florida’s mooring systems were installed as part of a statewide pilot project to regulate anchorages and to minimize environmental damage to the bottom. As Practical Sailor’s report on mooring systems revealed, all but one of the moorings in Marathon, Florida were still intact after the storm. Irma tore dozens of boats free from their moorings, but most these failures were linked to the owner-supplied pennants.

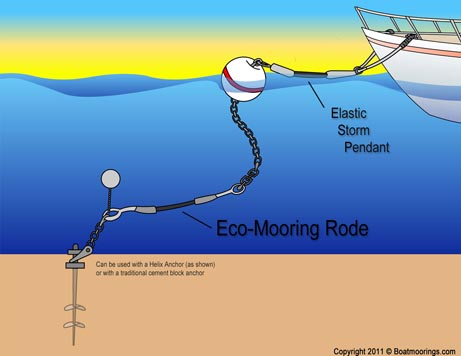

Three manufacturers offer products in this class. Eco-mooring System is effectively a super, heavy-duty bungy cord. It operates on the same principle as others like it, including the Seaflex Mooring System and the Hazelett Mooring System. These mooring rodes incorporate an elastic rode that allows mooring fields to pack more boats into smaller spaces. The elasticity also helps reduce shock on boat hardware.

We haven’t yet tested these systems, but we have taken a close look at how these moorings fared in Hurricane Irma. Prior to that report, the second most recent discussion of mooring holding power was published in 2009.

A couple other mooring-related products on our radar are the new helix-type mooring anchors offered by the same company that sells the Spade anchor in the U.S. These also held very well in Hurricane Irma. We should mention that similar screws installed by a professional contractor here in Sarasota, Fla., initially failed to meet specified pull tests, so it is important to carry out post-installation load testing.

As marine surveyor Jonathan Klopman pointed out in response to our discussion of elasticity in anchor rodes, the topic of how much stretch is a good thing is a hot topic so to speak. Heat-induced friction in nylon rode, it seems is on everybody’s mind.

Because of this, we are also interested in evaluating New England ropes approach to storm moorings. In the New England Ropes system, the cyclone mooring pendant (set between the mooring ball and the boat) is made of two components-a length of low-stretch Endura 12 to handle abrasion on the boat and a high-grade nylon mooring pendant that goes from it to the mooring ball. New England Ropes has also launched a new line of chafe protectors, which we will be pitting against the best chafe protection from our last chafe-guard test.

There’s plenty to say about this topic, but the most important thing is this: The time to plan your hurricane strategy is long before the storm hits. Practical recently published a multi-volume Hurricane Preparedness Guide ebook exploring the methods to prepare your boat in port or on land for extreme winds — whether it’s a violent squall line, a ferocious Norther, or full-blown hurricane. Unlike other storm preparation guide, ours delves into the nitty gritty details including mooring pendants, snubbers, anchors, docklines, etc.

Use a Clearstow boat curtain storage bag for you clear vinyl curtains

I have been using the Davis Shockles to augment my three-strand nylon dock lines for six seasons. I am on Lake Erie. We have fixed steel docks at my yacht club and every season we are exposed to occasional storms with winds over 45 knots. For example, we had one last July with wind gusts over 55 knots according to NOAA. Our docks are open to the wind in all directions except from the south. Obviously we are not exposed to the hurricanes of the southeastern US coast and the Gulf of Mexico, but we still get surge and heavy windage. The Shockles seem to be similar to the products described in your article for mooring balls. I have been very satisfied with the Shockles. I have not had any broken dock lines or any damaged cleats.

Marina Cortez in La Paz, BCS, Mexico uses a matrix of shock-absorbing cables anchored to the bottom rather than being shackled to vertical pilings. This technology has proven to survive storms from Mexico to Alaska, but the downside is when even wakes from large powerboats can set it to “galloping”, and storms make it impossible to walk.

When Hurricane/TS Norman passed La Paz my (heavy) trimaran was bobbing out of sync with the dock, as were most boats. Several of us sustained pulled cleats, snapped lines and/or banging against the dock. Every technology has its weaknesses, so I am investigating a custom heavy-duty mooring just in case, although Marina de La Paz next door has barrier walls that subdued waves and even barred debris from entering during Hurricane Odile.