For two years, we’ve been soaking both our test boat and 11 test panels with 30 different antifouling paints in Rockhold Creek, a brackish tributary of Chesapeake Bay. Upon reaching the 24-month mark, we’ve finally pulled the test boat for paint and formally inspected the panels. To our surprise, many of our eyeball assessments have changed in the four short months since our spring in-water cleaning. And for this reason, the panels are going back in the water for another year. Never leave a movie until the credits have finished. There may be a surprise ending.

This antifouling paint test took place in brackish water, not seawater. Salinity in the test area swings from 14 percent to 30 percent that of seawater (measured), averaging about 23 percent. The nearby sailing waters range from 20-40 percent of ocean salinity. Salinity is highest in the fall and lowest in the spring. Low salinity, particularly below 15 percent, can cause both soft and some hard growth to fall away, as can freezing winter temperatures. Low salinity can also hinder the effectiveness of a few popular antifouling paints, most notably Interlux Micron 66. The paint has an excellent track record in salt water, but the maker advises against using it in a low-salinity environment because it can lose its potency in freshwater.

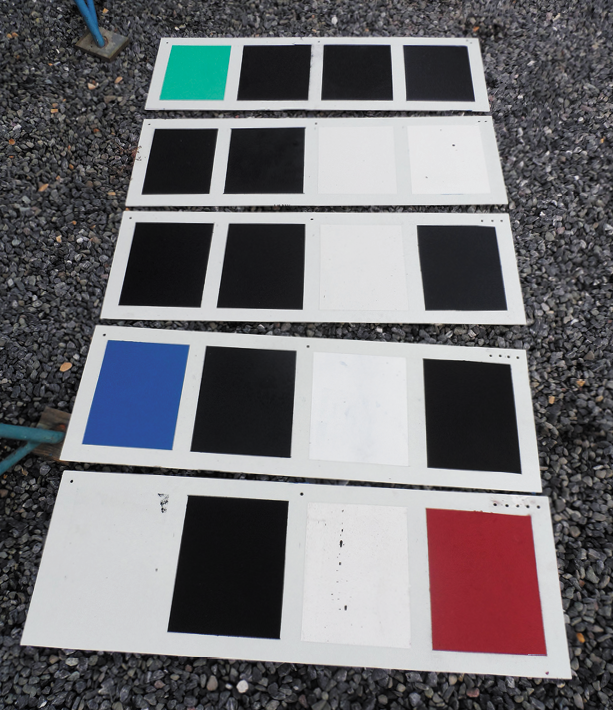

TEST PANELS, 24-MONTH INSPECTION

Our test panels were suspended from floats. They extended from about 6 inches to about 24 inches below the surface They were exposed to sunlight about half the day. We checked on the panels quarterly and formally inspected them at 12 months and 24 months. Before inspection, the panels were laid on the dock, sluiced off with a 2-gallon bucket four times in each direction to remove loose material that would be quickly flushed off underway, and graded them on a scale from 1 (Excellent) to 5 (Poor). A panel that is virtually clean and has no hard growth receives an Excellent rating. A panel with numerous barnacles or soft growth that is no better than a control panel with no antifouling receives a Poor rating. Panels in between these two extremes are rated relative to each other as Very Good, Good, and Fair. This time, we used our DIY canvas bucket to do the sluicing, which reduced the effort at least 50 percent compared with a 3-gallon plastic bucket (see “The Best Boat Bucket You Can Buy,” PS April 2023).

To help sailors narrow down the large field of paints, we loosely classified bottom paints into two categories: hard paints and ablative paints. Hard paints hold up well to underwater cleaning and can usually be burnished smooth for racing. However, they leave behind paint layers that build up and eventually will need to be blasted off mechanically with sand or some other medium. Also, some hard paints often require a light sanding before re-launch, or even lose their punch altogether if they are stored ashore for too long. Most ablatives can be hauled and relaunched without worries.

Ablative paints do wear away, however, so they won’t build up paint layers over time. There are two main types—bottom-tier workboat “soft” ablatives that slough away to activate more biocide, and more expensive copolymer ablatives that rely on their chemistry to release biocides at a more controlled rate. Although ablatives are often called soft paints, some are relatively hard and capable of maintaining a fast finish. These harder ablatives will usually resist light, underwater cleaning and are suitable for trailering.

The hard/ablative distinction is important because you might need to do some additional prep work when coating two dissimilar paints, such as a hard paint over an ablative paint. Whenever recoating with a new paint, it is important to check with the manufacturer regarding compatibility and any special surface preparation that might be required for overcoating.

The hard and ablative paints are further divided into five broad sub-categories that often overlap: freshwater paints, aluminum-friendly paints, racing paints, water-based paints (easy for the do-it-yourselfer to apply), and eco-friendly paints. To learn more about paint types (see above, “Choosing a Bottom Paint”). To see the final results among ablatives and hard paints see the tables on page 12.

WHAT WE TESTED: ABLATIVE PAINTS

Pettit Odyssey 60 and Odyssey HD, and SeaHawk Cukote, Colorkote, and Biocop all did well in our panel testing, but none compared with a 2014 can of West Marine PCA Gold we had on hand. Like many older antifouling formulas, PCA Gold contains the biocide called Irgarol, which has since been taken off the recreational market in the U.S., Europe, and other regions due to environmental concerns. Its availability is obviously uncertain. We did not test West Marine Premium (which replaced PCA Gold); it was not available at the start of the test. We surmise it will perform similarly to Pettit Odyssey HD. According to Kop-Coat Marine Group, owner of the Pettit brand and manufacturer of West Marine Premium, the two paints are very similar in formula and performance.

Bottom line: You have several good choices in the ablative paint category. The Pettit Odyssey paints—a new line—are performing well, and Seahawk’s high copper paints—Cukote and Biocop—have consistently done well in our testing. If you are looking for an ablative paint for a brackish environment, compare pricing among these at your local yard and find out which, if any of these three, they recommend.

WHAT WE TESTED: HARD PAINTS

Among the hard paints, Pettit Trinidad 75 and Trinidad Pro were clearly the most effective –and this is consistent with previous tests.

In panel testing, the hard paints were not quite as clean as the best ablatives at 24 months. This is not surprising. In several previous tests, we’ve found that the top-tier ablatives can repel hard growth for 18-30 months (depending on the environment). Hard paints, especially on boats that sit in a slip, will benefit more from scrubbing as time passes. The scrubbing exposes more biocide and helps extend protection beyond 18 months.

As with all six panel-tested paints that were also applied to the test boat, the hard paints performed better on the boat. In our hull tests, hard paints were just as effective as the best ablatives (see “Real World Testing,” below). For example, Trinidad Pro performed better on the boat than it did on our test panel.

This is no doubt the result of the natural scrubbing action of sailing. As mentioned, hard paints can withstand regular diver cleanings better than most ablative paints. Scrubbing will also significantly improve boat performance. Our test boat, a Corsair F24, gains about a ½-knot in motoring speed and a little more under sail after scrubbing. This is well worth the brisk early-season swim in Chesapeake Bay.

You can hire a diver to gently clean an ablative paint, but you need to be more thoughtful about it. Some marinas do not allow you to scrub ablative paints because it can release higher concentrations of biocide. If you intend to scrub your ablative paint, consider harder ablatives or “hybrid” paints aimed at racing or trailerable boats, and avoid softer workboat paints.

Whichever paint you use, you should make sure your diver employs the least aggressive manner required. We recommend sticking with terry cloth towel for as long as it is effective before moving up to textured sponges. Once you break out the scraper for areas well below the waterline, the biocide is no longer doing its job and you need to start thinking about another haulout (see “Bottom Scrub Tips to Live By,” PS April 2020).

Bottom line: In panel testing, the hard paints were not quite as clean as the best ablatives after 24 months, but they performed similarly in actual use. For boaters in high fouling areas who want to keep their boat in the water year-round, a hard paint will extend the interval between haulouts, but it will also require more vigorous scrubbing beyond 18 months.

Pettit’s Trinidad line holds top spots overall for protection in brackish water. The downside of hard paints like Pettit Trinidad and International Paints Ultra is that they tend to build-up thick layers over the years, requiring periodic stripping of the antifouling paint. This is and onerous or expensive process, depending on whether you DIY scrape it or contract a soda blasting firm (see “Bottom Paint Makeover,” PS October 2015).

WHAT WE TESTED: SPECIALTY PAINTS

The two main antifouling sub-groups are copper-free paints and water-based paints. These can either be hard or ablative.

Copper-free paints are suitable for aluminum hulls or saildrives, which will suffer galvanic corrosion if painted with copper. They are also promoted as more eco-friendly than copper, but recent research suggests a controlled-release copper paint can meet the environmental goals in more strict jurisdictions such as California and Washington State. Concerned about the potential harm of introducing new biocides into the environment, both states have delayed implementation of strict copper paint restrictions, instead limiting use of copper paints to those that leach less than a certain amount of copper per day (see “Antifouling Paints for Brackish Water,” PS April 2022).

Water-based paints don’t have the volatile organic compounds (VOCs) of solvent-based paints, making them more pleasant to work with. They are generally regarded as more environmentally friendly because of this low-VOC content, but they often contain the same amount or more active biocide than solvent-based biocide, so their impact on the marine environment is the same.

Copper-free paints. In our panel testing, Total Boat Krypton (a hard paint) delivered good results for 18 months, but then seemed to suddenly lose all potency against soft growth. The soft growth that formed during the last few months was also the most tightly adhered of the test. The Krypton paint that we applied to the test boat hull, however, remained effective beyond the 18-month mark. After 24-months in use on our test boat, the Krypton hull section was nearly as clean as the Trinidad Pro hull section. Another copper-free product, Interlux CF, has done well in prior Practical Sailor testing and did so again for our Chesapeake evaluation. Epaint’s ZO also fared well.

Water-based paints. Paint manufacturers like to tout water clean-up as an advantage to using a water-based paints, but this can be misleading. Because of the paints’ other ingredients, including strictly regulated biocides, federal and state environmental rules do not allow you to rinse any of the antifouling paints in our test from brushes, rollers, or other application tools into a sink.

Yes, a water-based paint will prevent VOCs from entering the atmosphere. And it will be more pleasant to apply if you stay upwind and use a roller extension. You can also wear a respirator, but, even without one, your exposure during outdoor application should be in the safe zone, below the exposure maximums set by the Occupational Safety and Hazard Administration. The days of benzene and carcinogenic solvents are long past. Nevertheless, you should read the paint’s safety data sheet (SDS) and follow the makers’ recommendations.

Regarding the eco-friendly argument for water-based paints: being water-based does not mean a paint releases less biocide into the environment. The biocide content (primarily copper) in our most effective water-based paints were as high as that of our solvent-based paints. (See the adjacent article, “Choosing a Bottom Paint.”)

One good reason to choose a water-based paint is that they work—at least in our estuary environment. After 24 months in the water, Interlux Micron WA and Micron Aqua turned in solid performances, effectively keeping barnacles at bay.

Bottom line: If you are looking to reduce impact to an environmentally sensitive, brackish water estuary or you are looking for a copper-free paint for your saildrive, Totalboat Krypton fits the bill. In the field of water-based paints, the Interlux water-based formulas proved effective in a brackish environment, offer less exposure to potentially harmful solvents, and reduce the release of volatile organic compounds (VOCs).

CONCLUSION

For most sailors, this study has reached a practical end point. After two years, we haul all our test boats (in Chesapeake Bay and Tampa Bay) and re-paint. Among the ablative paints, testers were impressed with Pettit’s Odyssey 60 and Odyssey HD, along with Sea Hawk’s Cukote, Biocop, and Colorkote (which features a wide palette of color choices).

In the category of hard paints, testers gave Trinidad 75 and Trinidad Pro the highest marks.

In the growing field of copper-free paints, Total Boat Krypton performed amazingly for 18 months before starting to collect soft growth on the panel—but not on the boat. Interlux Micron CF also did well in the copper-free category. All the ePaints struggled in brackish water. This was a stark contrast to the excellent results that we saw in past tests in Florida, where some ePaint panels saw very little growth for the first year.

If you prefer a water-based paint, Micron WA and Micron Aqua did well. Keep in mind that these “eco-friendly” paints do leach copper.

Given the uncertainty surrounding the environmental impact of alternative biocides (as noted by state-funded tests in California and Washington) and given the performance of copper-free paints in our own testing, we conclude that copper is still king. If your aim is to protect the environment, try to stretch your painting cycle to two years and beyond, chose a paint that will minimize in-water cleaning, and clean the bottom in a responsible way that minimizes release of biocide with each cleaning.

We’re going to leave the panels in the water for another year, for a total of three years. Although most of us in high fouling areas are on a two-year cycle, some of these paints will likely last three years in low fouling areas or water with low salinity.

VALUE GUIDE: HARD ANTIFOULING AFTER 2 YEARS IN BRACKISH WATER

| MANUFACTURER | MODEL | SOLVENT/WATER BORNE | MULTI-SEASON | COPPER | ZINC | 2-YEAR (panel) | 2-YEAR (boat) | PRICE (gallon) |

|---|---|---|---|---|---|---|---|---|

| Total Boat | JD Select | Water | No | 25% | No | Fair | - | $134.00 |

| Spartan ✔ $ | Solvent | Yes | 38% | No | Very Good | - | $189.00 | |

| Pettit | Trinidad 75 * | Solvent | Yes | 60% | No | Excellent | - | $268.00 |

| Pettit | Trinidad Pro * | Solvent | Yes | 65% | No | Excellent | Excellent | $320.00 |

| Pettit | Trinidad HD ✔ $ | Solvent | Yes | 60% | No | Very Good | - | $230.00 |

| ePaint | EP-2000 | Water | Yes | None | 5% | Poor | - | $237.00 |

| ePaint ZO | Solvent | Yes | None | 5% | Good | Poor | $237.00 | |

| Ecominder | Water | Yes | None | 40% | Poor | Poor | $164.00 | |

| International Paints | Ultra-Kote ✔ | Solvent | Yes | 76% | No | Very Good | - | $260.00 |

| ✔ Recommended, $ Budget Buy, * Best Choice |

VALUE GUIDE: ABLATIVE ANTIFOULING AFTER 2 YEARS IN BRACKISH WATER

| MANUFACTURER | MODEL | SOLVENT/WATER BORNE | COPPER | ZINC | 2-YEAR (panel) | 2-YEAR (boat) | PRICE (gallon) |

|---|---|---|---|---|---|---|---|

| Total Boat | Krypton *$$ | Solvent | No | ~ 7% | Very Good | Excellent | $199.00 |

| Pettit | Odyssey 60 * | Solvent | 60% | ~ 7% | Excellent | - | $264.00 |

| Odyssey HD * | Solvent | ~ 40% | ~ 7% | Very Good | - | $232.00 | |

| Odyssey Triton | Solvent | ~ 40% | ~ 7% | Good | Excellent | $400.00 | |

| Seahawk | Color Kote ✔ | Solvent | Yes | 10% | Very Good | - | $245.00 |

| Cu Kote ✔ | Solvent | 50% | 10% | Excellent | - | $240.00 | |

| Biocop TF ✔ | Solvent | 60% | 10% | Very Good | - | $280.00 | |

| Smart Solution | Solvent | No | No | Good | - | $195.00 | |

| ePaint | EP-21 | Water | No | 50% | Fair | - | $137.00 |

| International Paints | Micron CSC | Solvent | 25-50% | 10-25% | Fair | Fair | $250.00 |

| Micron WA ✔ | Water | 25-50% | 10-25% | Very Good | - | $240.00 | |

| Micron CF ✔ | Solvent | No | 10-25% | Very Good | - | $290.00 | |

| Micron Navigator | Solvent | No | 2-10% | Good | - | $275.00 | |

| Micron Aqua ✔ | Water | 40% | No | Very Good | - | $240.00 | |

| West Marine | PCA Gold | Solvent | 40% | No | Excellent | - | $239.00 |

| ✔ Recommended, $ Budget Buy, * Best Choice |

Unless you’re prepared for more prep work than a light sanding, the first step in selecting a bottom paint is finding one that’s compatible with what’s on your hull now. All the manufacturers in our test will provide guidance on this, either over the phone or on the company website.

Generally, you can repaint a hard paint with either a hard or soft paint, while a soft ablative paint being coated with a hard paint will need more sanding or a tie-coat primer. Bare fiberglass or metal will require a primer, and aluminum components like saildrives need a special copper-free paint that won’t induce potentially disastrous galvanic corrosion. Before plunking down nearly $250 or more a gallon, consider where your priorities lie.

The water-based advantage: With no unpleasant solvents, water-based paints are easy and safe to apply. The brushes and leftover paint probably still contain copper and cannot be cleaned or flushed down the drain.

The environment: Studies in California and Washington have resulted in regulatory limits on copper leaching, and generally existing two year paints could meet them. Both states backed off from a copper ban due to concerns that copper-free paints may not be as effective, but more importantly because the risks of non-copper antifoulants were not well understood and can be worse. Reducing copper leach rates was believed to be the safest way to alleviate environmental harm. All of the major manufactures reformulated their paints with these rules in mind. The EPA has discussed adopting the CA/WA copper leaching rate as a federal standard, but there is no movement at this time. There are some very effective copper-free paints, but whether they are actually safer is uncertain.

No paint buildup: Over time, ablative paints wear away, and with a good power washing, two years of sailing, and a good sanding, build-up can be reduced to near zero. Hard paints generally form thick layer cakes.

Quick recoating: Hard paints can take a second coat sooner than ablatives, although some of the newer copolymer ablatives can be recoated after four hours or less. Thin-film Teflon paints for racing boats can dry in a matter of minutes.

Haulout schedules: Some paints (typically hard paints) lose their effectiveness if not launched within a certain time frame, or if the boat is hauled out and then relaunched without painting. Some paints you need to lightly sand or scuff to reactivate before relaunching.

Trailerability: Some ablative paints are designed to resist abrasion from trailering. So-called hybrid ablative paints like Seahawk Talon, and Bottomkote NT are examples of ablative paints that have durable finish. Most hard paints will trailer well, but some paints—Trinidad among them—will require refreshing with a light sanding or scrubbing to reactivate the paint if left out of the water too long (see Inside Practical Sailor blog post “Hard Anti-fouling Paints and Haulouts”).

Our antifouling test protocol is simple. Painted fiberglass panels are suspended just below the water surface. Every six months the paints are sluiced with water, rated, and then placed back in the water. The rating scale is as follows: Excellent, no slime; Very Good, little soft growth relative to field; Good, some soft growth relative to field; Fair, more soft growth relative to field; Poor, barnacles and hard growth firmly attached.

1. Most test paints were black. We found no clear connection between color and performance.

2. Before sluicing, most panels were still covered with slime. The budget single-season red paint on the far left segment, JD Select, rated Fair after two seasons. The far right segment has no antifouling.

3. Soft growth clung to all the samples before sluicing; some had barnacles. From left, water-based Micron WA, EP 2000, Odyssey HD, and Spartan. All except EP 2000 rated Very Good after two years.