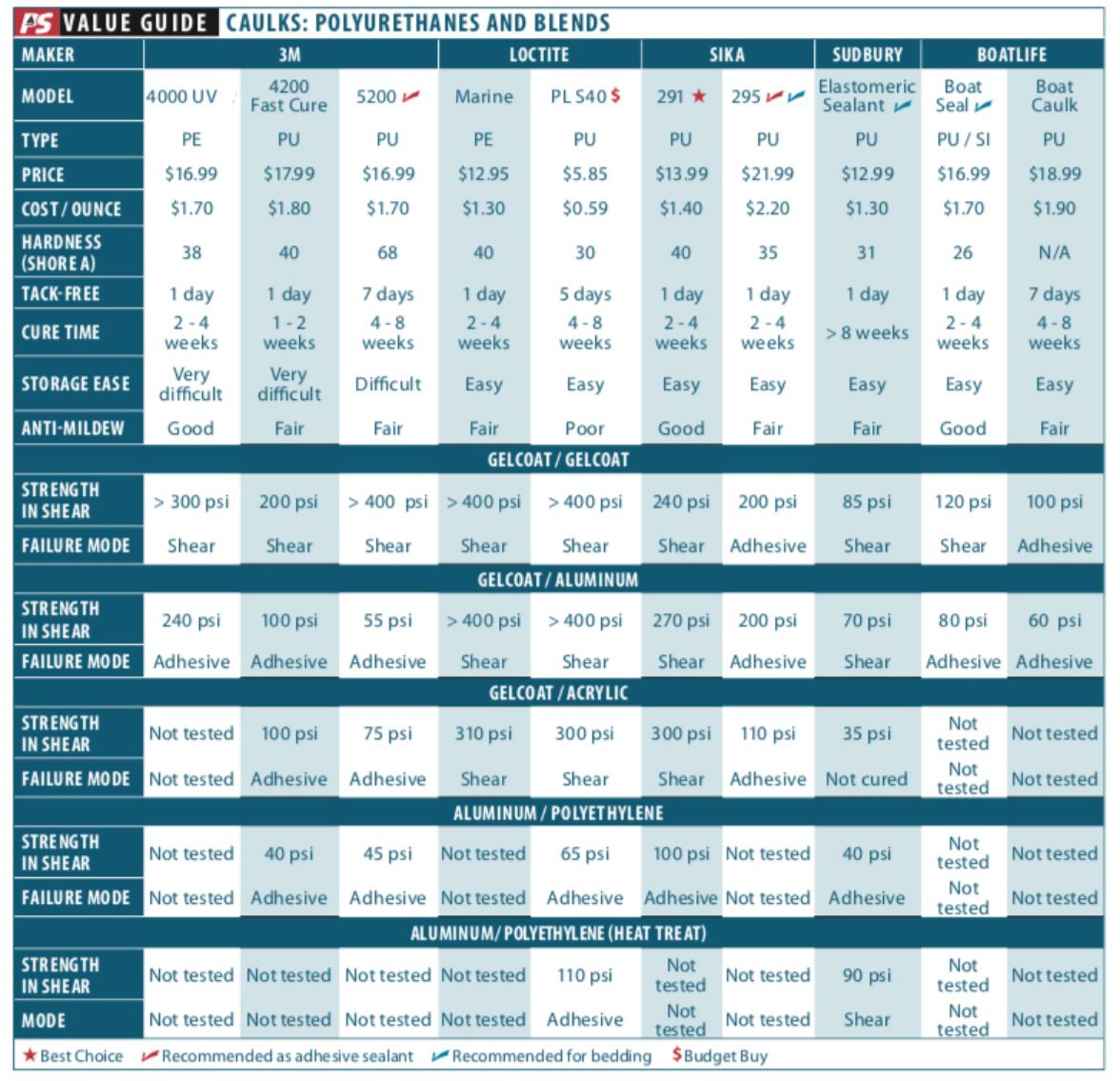

We expect a lot from sealants. They must withstand UV, salt and cleaning chemicals, bond to everything, flex to absorb mechanical and thermal strains, be strong but removable when equipment needs serviced, and stay white. Wow. In PS Marine Sealant Adhesion Tests (December 2016) we tested the shear strength of many caulks on many materials and delivered a few tentative recommendations. Three years later, it is time to follow-up with field observations.

What We Tested

We tested a field of leading sealants including 3M 5200, 3M 4200 Fast Cure, 3M 4000 UV, Sika 291, Sika 295, Loctite PL S-40, Loctite PL Marine, Boat Life Caulk, Boat Life Seal, and Sudbury Elastomeric Sealant.

How We Tested

While making up shear strength samples back in 2015, we also bonded twenty 1.25-inch by 6-inch fiberglass strips at a90 degree angle and placed them on the roof to endure nature for three years. Every few months we flexed them 90 degrees a few times and observed changes. In this final look, we see how well they held up to weathering, with particular attention to mildew resistance, since mildew staining is a common complaint from PS readers.

Observations

For flexibility and bonding, the big loser was Boat Life Caulk. While it has enthusiasts as a bedding compound for teak, it did not adhere well to any test surface and peeled away cleanly from gelcoat within a few months. 3M 5200 proved to be relatively inflexible, necking (drawing permanently thinner under strain without tearing) and eventually tearing from the strain, but since 5200 is more accurately an adhesive than a sealant, this is not a strong criticism. At the final checkup, Loctite Marine exhibited some necking and minor pealing, and Sudbury Elastomeric sealant showed some tearing.

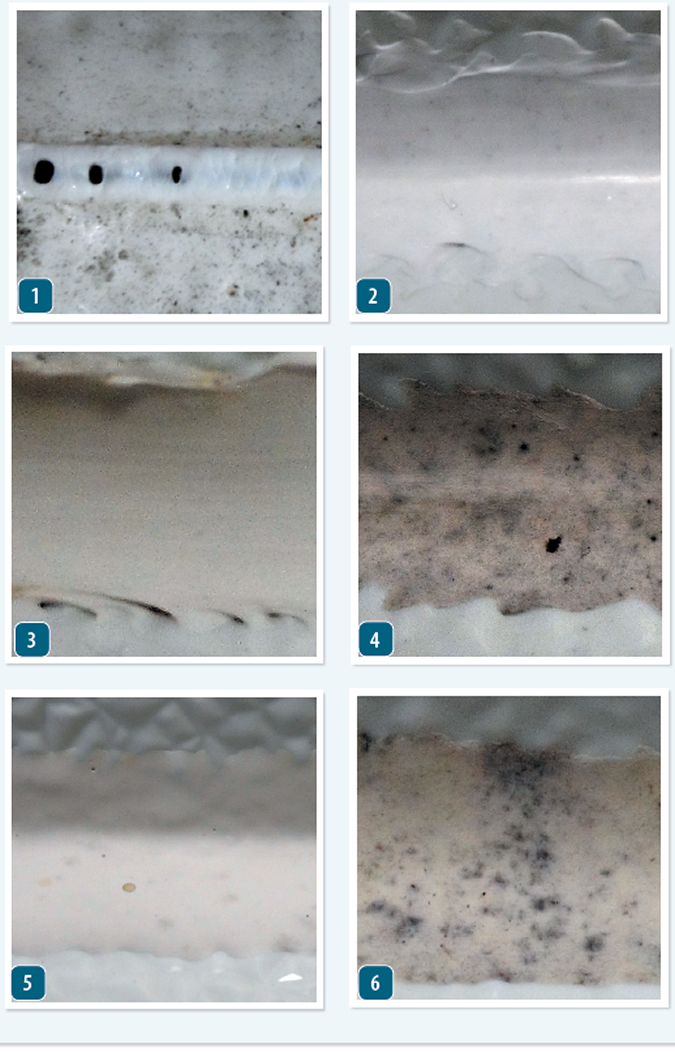

The second surprise was the significant difference in dirt attraction. At the 6-month and 1-year checks we saw significant spots that looked like mildew growth, but when wiped with a cloth and plain water, they all came clean. And yet, there were differences related to surface texture. Boat Life Seal, which contains silicone, repels dirt, while the polyurethane sealants attracted dirt. The downside of silicone is that it can inhibit bonding in subsequent projects (see PS January 2017).

After three years, the picture was different. None of the samples would come clean with plain water, so we scrubbed them all with a typical deck cleaner in the hope of revealing differences. In fact, with the exception of Loctite PL S40, they all came clean, though Boatlife Seal and Sika 291 were slightly easier to clean.

Product Reviews

In addition to reviewing our three-year observations, were also going to ask you to read back to PS December 2016, when we tested shear strength bonded to a variety of materials. While appearance and flexibility count, strength and durability are often more important. The best bonding and bedding sealant may not be the best choice for a long and prominent seam. It also depends on your priorities.

3M 5200

Intended as a permanent bonding adhesive, not a sealant or bedding agent, 5200s increased stiffness worked against it in the flexibility test. It took more than twice as much force to flex the samples, in spite of the fact that 5200 is thin and only about 50 percent as much material was present in the joint.

There was also some damage to the caulk in the form of slight necking and eventually tearing, although the bond remained tight. In testing, adhesion to plastics and aluminum were only so-so (3M recommends special primers for metals). Oddly, we know it often bonds tenaciously to aluminum hatch frames.

Bottom line: Recommended as a fiberglass adhesive, but not as a flexible sealant.

3M 4200 Fast Cure

Good flexibility, good adhesion, and superior weather resistance gave us a lot to like in this round. However, inconsistent bonding to aluminum and plastics during shear testing keeps it out of the top tier.

Bottom line: Recommended for sealing fiberglass.

3M 4000 UV

Good flexibility, good adhesion, and superior weather resistance made this a top performer. Removal may be a problem, since it is strong and we have not tested removers on polyethers. It was difficult to judge the effect of mildew because the sample was black, however, we examined it very closely with a magnifying glass and concluded there was no significant growth.

Bottom line: A Best Choice for most applications.

Sikaflex 291

Much like 3M 4200 Fast Cure, but with more consistent bonding on a wider variety of materials. It came clean easier than most and retained flexibility.

Bottom line: A Best Choice for most applications.

Sudbury Elastomeric Sealant

Flexible, weather resistant, and consistent in bonding, it is not as strong as other sealants in the lineup, making it a good candidate for hardware that will require removal. We liked that the sealant always failed in shear before the bond failed. However, it failed when constantly immersed in water, puckering and coming loose. It also suffered minor tearing in the flex test.

Bottom line: We like other sealants more.

Loctite PL S40

A bargain product from the hardware store, its really fighting out of its weight class, competing with products costing 2-4 times more. And yet it delivered the same flexibility, superior strength and a better range of adhesion than any other product. It withstands continuous water immersion, even when bonded to polyethylene (15 year test on some long splits in a molded fish pond). Its weakness is a strong tendency to yellow, poor resistance to mildew growth, and more surface weathering. Its tough to clean.

Bottom line: Our Budget Buy and an excellent option for tough adhesion problems, but not a great choice for conspicuous seams. Marine quality for around-the-house use!

Loctite PL Marine

Another polyether, like 3M 4000 UV. We liked the weather resistance and flexibility. Unfortunately, it let us down with minor necking and bond failure issues.

Bottom Line: We’re still looking for a reliable polyether.

Boatlife Life-caulk

This sealant failed to bond effectively in our shear testing, and it failed the flexibility testing completely, debonding completely the first time the samples were bent. While you may like a sealant that is easy to remove, we think bond failure is never acceptable.

Bottom Line: Not acceptable.

Boatlife Life seal

With better bonding and flexibility than Boat Life-Caulk, this product performed acceptably. It was also very mildew resistant. However, it does contain some silicone, and we are not sure how this might affect subsequent bonding.

Bottom Line: Recommended if you are OK with silicone.

Conclusion

We chose not to declare a single best since several of the products impressed us. We like Sika 291 and 3M 4000 UV for good bonding, flexibility, and weather resistance. Loctite PL S40 has an amazing low price, best overall bonding and physical properties, but some unfortunate appearance problems. Boat Life Seal is impressive if you don’t mind silicone, but wed avoid Boatlife Life Caulk. 3M 5200 is good for permanent bonding.

This is just one of several caulk tests that Practical Sailor has carried out over the past two decades, but it is only the second long-term test since 2005. For a comprehensive look at caulks and sealants, be sure to explore the archives at www.practical-sailor.com. A simple search under sealants will turn up most articles. The online version of this article will also have some links.

- Tour our surprise, 3M 5200 began losing bond strength by the third year.

- Boatlife Life Seal cleaned up really well over time.

- Loctite Marine did not go on as smoothly as some of the other products, but it cleaned up well.

- Even after cleaning, Loctite PL S40 showed a significant amount of mildew staining.

- Sika 291 cleaned up well and held a tenacious bond, even at the edges where the caulk was thinly spread.

- Mildew crept deep into Sudburys Elastometric sealant. Only a thorough bleaching could eliminate the stain, but this also caused yellowing.

A correction to your Table: Boatlife Boat Caulk is a Polysulfide (similar to 3M 101), not a Polyurethane.

You left out our clear winner: Teak Decking Systems SIS-440…

You are right, it has amazing adhesion and I have yet to find an air bubble in a tube, although there is often leakage from the cartridge into the caulking gun, grrr. Also reasonably priced.

And butyl?

Has anyone tried Dow Corning 795? The best stuff for putting in acrylic/plexi windows in my opinion.

To Alan Keene, we used 795 but black to bed a window; it’s held up perfectly. We used white to bed a new head light (pane of plastic in the head) and vent, but it’s too new to say at length. For waterproofing, you have to make sure the entire area used is covered. We have a couple of small rivulet-level channels to deal with. Our solution will be to dig out the perimeter and recaulk that area. But being a silicone, we’ll have to be very fussy about prep.

Two items:

To Alan Keene, we used 795 but black to bed a window; it’s held up perfectly. We used white to bed a new head light (pane of plastic in the head) and vent, but it’s too new to say at length. For waterproofing, you have to make sure the entire area used is covered. We have a couple of small rivulet-level channels to deal with. Our solution will be to dig out the perimeter and recaulk that area. But being a silicone, we’ll have to be very fussy about prep.

Cosmetically, in addition to it being head and shoulders above any other we’ve ever used, TDS SIS-440 is absolutely stunning. While it can get dirty, or maybe contain some mold, those are strictly surface issues, and disappear with a light wipe with only water.

It also is a water cleanup, and application is a dream compared to any other out-of-a-nozzle stuff I’ve ever had my hands on. Before it sets, it will wipe cleanly off whatever tool you may be using. It skim/skins very nicely and predictably, with plenty of work time, yet able to start quickly (perhaps 10 minutes or so) for lifting tape.

It also repairs – such as we had, where we inserted a chunk of toe rail when we replaced our chocks. Cut out the old, making an outgoing “v” on both ends (slant the edges, ramping to the top) prep it like new (sand, vacuum/blow, acetone wipe – which, by the way, doesn’t affect the cured caulk) and apply. Be finicky with your tool (your finger will work, if that’s what you use, but we prefer a triangular rubber nipple on a tool, the 3 points being different radii), and it will fair cleanly; a month later if you don’t know where it is you won’t see it. If you DO know where it is, it will pass the 3′ test.

I can’t imagine this was not included in the test. Other than strictly as an adhesive, this is a gross omission…

I have had great success with BoatLife Calk as a BEDDING Compound. My bedded fittings haven’t leaked in 17 years, and fittings that needed to be removed after 12 years came off easily. There was no water ingress under the fittings, and cleaning the area to reinstall the fittings was easy. The calk that was in the holes around the bolts hadn’t cured making the removal and reinstallation a cinch.