Southern sailors often put their boats away for a few months when the water gets a little cool. Northern sailors have a more definitive reason; they put their boats away when the water gets hard. Often, freezing is limited to harbor areas, where shallow water, freshwater input, and limited tidal flushing encourage ice formation. Far north, you can walk on it for weeks, while in the mid-Atlantic, the layer is often thin and transitory. And while a few inches of ice are generally harmless to a sound boat, thick moving ice can damage paint, exposed steering gear, and planking. Although we can’t make the weather any warmer, there are measures boat owners can take to keep ice at bay.

Many areas of the country, however, are not worth the trouble. Moving ice is a serious hazard, and the only sure protection is to get out of the way. Marinas in rivers or downstream of rivers are subject to moving floes, often requiring that all boats and floating docks are hauled for the season.

Tidal brackish and seawater areas present a different case. Even in very cold climates, harbors will not freeze because salt water freezes at about 28 degrees and because the tide brings warmer, deep water in twice a day. The ice that does form is often slightly mushy, the result of the salt concentrating as the fresh water crystallizes out, creating tiny pockets of brine. However, harbors in estuaries like Chesapeake Bay are often located in freshwater creeks where the salinity is considerably less than bay itself. The bottom line is that you must seek local knowledge to get an accurate measure of what can be expected and what works.

Can a Deicer Reduce the Risk of Bilge Freeze–Ups?

Yes. After all, the working principle is that of bringing warmer water up from below. Just one to two degrees can make the difference.

Liveaboard boats in marginal climates typically do not need deicers. The heat from the hull keeps a few inches ice-free. However, this only works with liveaboards; leaving heaters running unattended is very bad practice and is forbidden by most marinas.

What About Diffusers?

It seems many sailors refer to all deicers, both propeller-driven and compressed-air systems, as bubblers, not understanding the difference. Like the air stones found in aquariums, compressed-air systems use fine bubble diffusers to provide lift both for circulation and for moving large volumes of water. Though inefficient in shallow water, these are the way to go when water is deeper than 15 feet. Some models can function in water as deep as 50 feet. They are less effective in shallow water because they move less water; they require a deep reservoir of warm water and a tall column to do their best.

One advantage of these systems is that they will not clog. Disadvantages include slightly increased installation labor and less flexibility during the season; they can’t be easily moved once placed, or moved at all once the ice sets in.

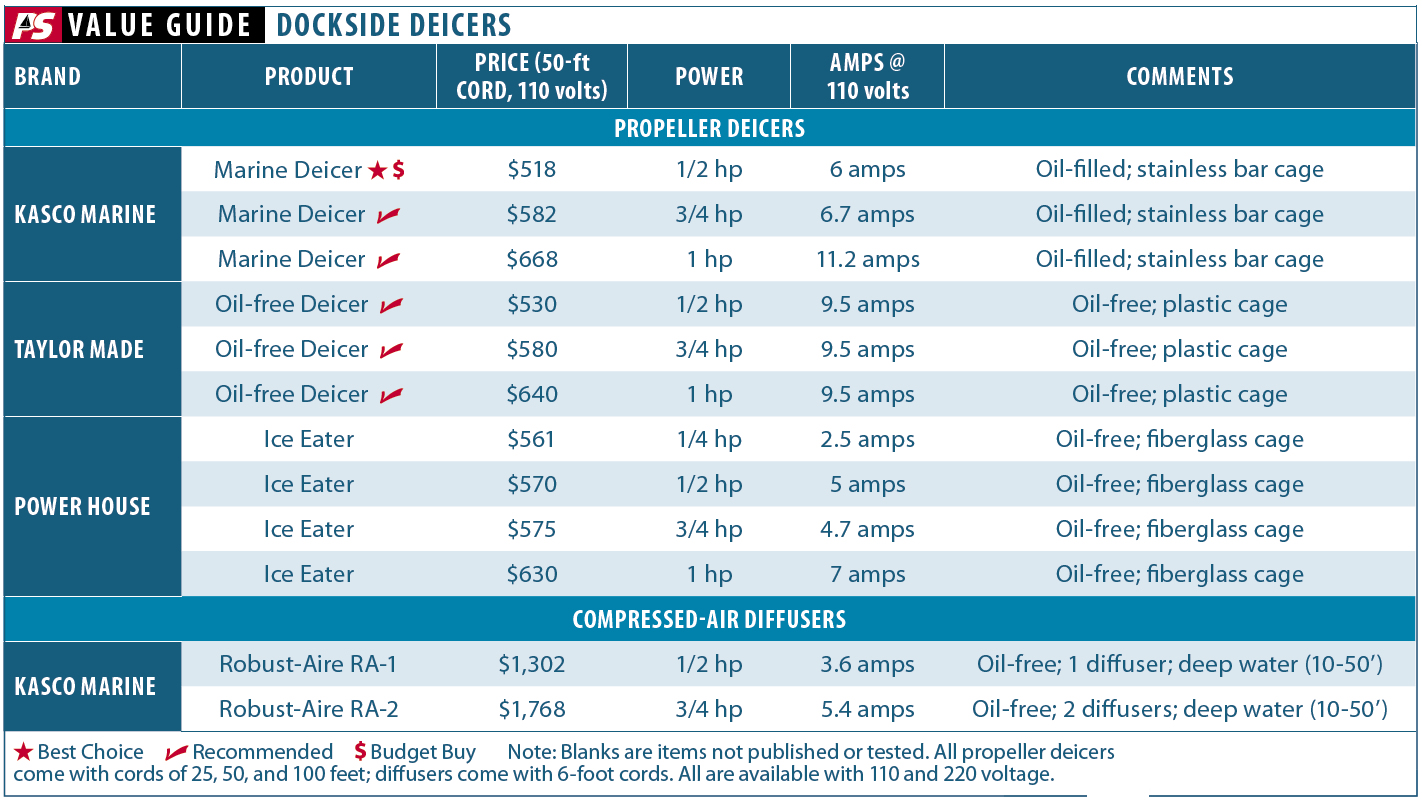

For this report, we compared one diffuser system to a handful of propeller-driven deicers, with an eye toward performance and longevity.

What We Tested

We tested propeller-type deicers from Kasco, Taylor Made, and Powerhouse. Very similar in principle, these deicers turn a plastic propeller attached to a direct-drive electric motor inside a sealed metal cylinder. A metal or plastic cover surrounds the motor and propeller, providing protection from floating debris. The deicers can be fixed-mounted to docks, but all the units we have used have been temporarily mounted, suspended from lines. This is a common installation in small marinas where only a few diehards keep their boat in through the winter. The power cords are long enough to reach a secure dock location where they can be covered, and are generally controlled by a separate thermostat or timer. We have also used Kasco Robust-Aire diffuser systems in industrial settings.

How We Tested

The focus of the PS evaluation was on durability. PS tester Drew Frye has used Kasco, Taylor Made, and Powerhouse deicers on his boats for 20 years. He has used the same deicers in industrial stormwater ponds, running multiple units continuously for 20 years, 24 hours a day, 7 days a week. This has given him a long failure history to draw from, equivalent to 60 years of continuous use or about 1,000 years of seasonal use. He has also run Kasco and Taylor Made deicers in natural-gas drilling frac water flow-back ponds for five years. The ponds are often hypersaline, as much as 10 times higher in salt content than the ocean, and are loaded with abrasive solids from drilling and drilling mud—a very tough testing environment.

Observations

Environmental Hazards

Propeller-driven deicers are prone to some environmental hazards. Plastic bags love to clog the inlet screen and wrap around the prop. While these do not generally cause any damage, they do reduce the output dramatically and sometimes cause considerable vibration. Thus, any deicer should be checked for clogging at least every two weeks. The Kasco unit has a metal bar frame that is more effective at catching trash. As a result, it clogs more frequently, but it also provides better protection against prop breakage by sticks.

Occasionally, a waterlogged stick will find its way into a deicer prop. Depending on the size, this is likely to break the plastic propeller. The props are easily changed, and it is best to keep a spare on hand; users can plan on replacing the prop every two to five years of seasonal use.

Chafe Protection

Unless the suspension lines are well protected from chafe, they will break, and the deicer will fail within a few days due to abrasion. We recommend using 3/8-inch nylon or polyester rope, at a minimum, for temporarily mounting a deicer.

Oil-Free Designs Not Worthwhile

Many deicers are filled with oil to reduce the potential for seal leaks. There are oil-free models, but every time those units are turned off, a partial vacuum forms, and even a minor pinhole can draw water into the housing. We do not see oil-free design as a worthwhile benefit when weighed against reduced reliability.

Horsepower Requirements

Horsepower requirements will vary by location, so users may need to consult a local expert. A higher-horsepower deicer will move more water and clear a larger area. On the other hand, it will cost more, clog more often, place higher loads on the securing lines, and consume more electricity. We only recommend the larger sizes if your boat is exceptionally large or if local knowledge suggests you should. Electricity will cost about $50 to $200 per year, depending on climate and deicer size.

Shaft Anodes

Shaft anodes are essential. Available from the manufacturer or marine suppliers, these last through several years of seasonal use and are standard sizes.

Kasco Marine De-icer

Deicers with oil-filled motors like Kasco’s have proven more reliable than their oil-free competitors. When an oil-free motor develops a tiny shaft leak or cools when turned off (even if you leave it on, the power will fail at some point), water enters the motor and failure is immediate.

We like the durability of the Kasco’s metal cage. (We have had several cracks in the plastic Taylor Made cages.) We also like the Kasco’s improved trash screening; though it is marginally more likely to clog with bags and flotsam, this is preferable to a broken prop. We have tracked their durability in stormwater pond mixing service for 20 years (0.5 horsepower) and noted that failure occurs after about two to three years of continuous running (equivalent hours to 15 to 100 years of seasonal use) when the shaft seal fails. All premature failures were from contact with the bottom.

Bottom line: Exceptional endurance in industrial environments makes the Kasco our Best Choice.

Taylor Made Oil-Free Deicer

We no longer use the Taylor Made Oil-free deicer in industrial applications because we had to replace too many props (the plastic shroud does not screen sticks well) and found the average time between failures to be only one year when used continuously (equivalent to four years seasonal use).

One oil-free Taylor Made unit we used survived 10 years of light seasonal use with two broken propellers. It was working fine when we sold it along with the boat we used it on. We now have the same model on our current boat, where it has lasted five seasons so far. The prop fouls more frequently than other designs, presumably because more water passes through the prop and because the screening is less efficient, but we find the shroud mounting holes convenient.

Bottom line: Recommended for high flow, but expect to replace a few props.

Powerhouse Ice Eater

Also an oil-free unit, the Powerhouse Ice Eaters motor is protected from bottom damage by a very durable fiberglass shroud, eliminating one common failure mode. However, though we have tested only one unit (0.75-horsepower), it failed after eight months of continuous service due to a shaft seal leak. Bad luck, perhaps, but we have heard other reports of shortened seal life. The 0.25-horsepower version will manage only single slips in moderate climates, but promises low power consumption. Were not convinced that this is much better than a thermostat-regulated 0.5-horepower unit running fewer hours.

Bottom line: We prefer oil-filled deicers.

Kasco Robust-Aire Diffuser

Our experience with the Kasco Robust-Aire diffuser system is in deep ponds, where propeller deicers could only scratch the surface. We have also seen Robust-Aire diffusers used in marinas to clear a path to open water; they do not disrupt boat traffic.

The Robust-Aire’s installation is more complicated, involving simple wiring, cabinet installation (pre-wired), trenching for hose, and laying the hose and diffusers in the water. However, there is nothing to clog or break in the water, and operation has proven quite dependable. Price depends on the system’s complexity; mid-level, cabinet-mounted compressors run about $1,320 for a one-diffuser system and about $1,768 for a two-diffuser system, although many designs are possible.

Bottom line: This is not for the individual boater. It is aimed more at marinas that need a deep-water solution.

Conclusions

When it comes to deicers, proper installation is key. We’ve addressed many of the key points in the accompanying Installation Tips for Deicers. As long as the mixer is positioned to draw warmer bottom water up toward the boat and is not allowed to contact the bottom or any piling, long, reliable service is the general rule.

Do check on the deicer every two weeks at a minimum; you can’t predict when a trash bag will cover the inlet or clog the blade, stopping flow. It’s also wise to keep a spare prop on hand. We like oil-filled, submerged deicers, and of all the units we tested, the Kasco stood out as a Best Choice, for its simple, robust performance.

Price updates: Kasco Marine Deicer starts at $1,004, Taylor Made starts at $555, Power House starts at $900.

This article was published on 19 October 2016 and has been updated.