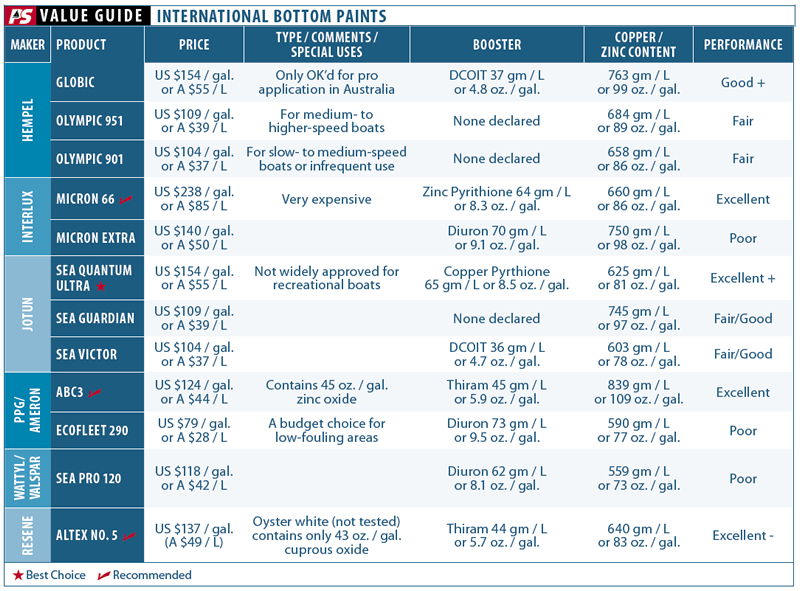

Practical Sailor has been conducting antifouling paint trials for years, but our focus almost exclusively has been on those paints that can be bought off-the-shelf at U.S retailers or are widely available in U.S. boatyards. Nevertheless, we often receive email questions from sailors abroad regarding antifouling paints sold in other countries. A number of readers have also have asked us about certain paints that are generally used only on commercial ships. These commercial paints can sometimes be procured at shipyards in major ports both in the U.S. and abroad.

In an effort to add more data to our already overflowing database on bottom paints, we commissioned our man Down Under, Jonathan Neeves, to have a look at antifouling paints that are commonly found in New Zealand and Australia and that are distributed throughout Southeast Asia and the Pacific Rim. These paints also are found in other corners of the planet, including Europe, Africa, and parts of South America.

Photos by Jonathan Neeves

The testing took place in Sydney, Australia, where conditions are quite different from any we have encountered at previous test sites, including Long Island Sound, Floridas Gulf Coast, the Florida Keys, Chesapeake Bay, and Rhode Island. Although some of the foreign antifoulings bear the same names as products sold in the U.S. or Europe, the formulas may differ slightly to comply with local environmental laws.

Many of the antifouling paints available in America and Europe are simply not available in the Asia-Pacific region. There are many reasons for this, but cost is certainly one. Environmental laws vary from country to country; regulatory approvals are expensive and time-consuming, so a manufacturer must be assured of a fairly large market in order to invest in the process. For the same reasons, formulations available in the Asia-Pacific region are often not available in Europe or North America, where the approval process can be particularly onerous.

Bottom-paint test results can vary widely by season and location. Because we have no baseline for this test, our conclusions will not be particularly binding. Our tests in Australia are, at best, indicative. However, it was interesting to note that one of the best antifoulings in our Sarasota, Fla., test also did well in Sydney.

What We Tested

From International Paints, part of the Dutch company Akzo Nobel and known as Interlux in the U.S., this test included both Micron Extra and Micron 66.

From Jotun, a Norwegian company selling antifouling paints worldwide but with a relatively small presence in America, we tested Sea Victor, Sea Guardian, and Sea Quantum. The latter comes in a number of formulations, each one optimized for boats that travel within a certain speed range. We tested the SeaQuantum Ultra for vessels moving at 0 to 14 knots.

Resene, a New Zealand company with coverage in Southeast Asia and the Pacific, sent Altex No. 5, a formula that is widely known and has a good reputation in Australia.

Wattyl, an Australian surface coatings company that was bought by the U.S. giant Valspar in 2010, supplied its multi-season paint, Sea Pro Cu120.

Hempel, a Danish company with an international presence in the antifouling market provided Globic, which is restricted in Australia to commercial and naval vessels. We also tested its Olympic 951 and 901, which are aimed at the recreational market.

The American company PPG provided ABC3 and Ecofleet 290 for testing. The paints are also sold under their Sigma and Ameron brands.

How we tested

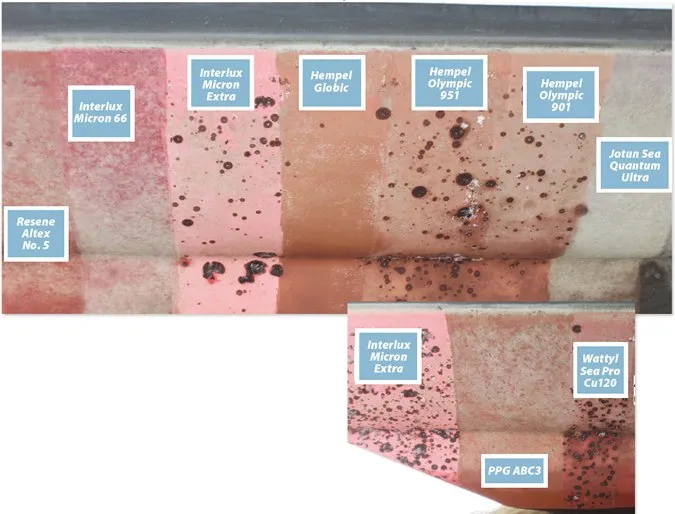

The initial tests were conducted according to the same protocol that we follow in Florida, using static fiberglass panels that do not move but are rinsed once before testers rate the paints at six-month intervals. Because all the paints in this test are ablatives, which generally perform better on moving vessels (water friction promotes self-polishing to expose fresh biocide), the overseas distributors that supplied test paints suggested that we put the paints on a boat or some other moving test platform. We concurred and launched a field test aboard Neeves Sydney-based 38-foot catamaran.

All test paint was supplied by the manufacturers. We requested red paints because we prefer high-visibility colors for multihull bottoms; should the boat capsize, having a highly visible hull color offers a better shot of being found in an aerial search. We did end up with one blue and one black paint.

We divided the amidships section of the cats hulls into approximately 12 one-foot-wide vertical strips from the waterline to the keel base. We numbered the paints and applied them to this area. Two hulls gave us four hull sides to work with, and we changed around the order to keep things fair. All paints had a fair chance of being near the bow or well shaded by the bridgedeck, etc.

We then applied the low-copper paints to the bow sections, one paint to one side of each complete bow, and another four paints were applied to the stern section; we applied the remaining four paints to the two rudders, one paint per side.

All paints were applied by roller. We applied three coats of each paint (one coat per day), allowing more than the minimal time for each paint to dry prior to re-coating. All the paints were stirred with a mechanical stirrer prior to application. We had copious amounts of paint and did not need to skimp (a common problem for self applicators) and checked coating thickness with paint gauges supplied by Jotun.

Launch was about 36 hours after the final coats. During the test period, we beached the catamaran every three months and took photographs. As fouling developed, we wiped the hulls down, but the coatings that developed fouling did not improve after each cleaning.

The objective was to find coatings that would offer at least 12 to 24 months of service. We found that the props need treatment (zincs and paint) every 12 months, so ideally, a hull paint with a 12- or 24-month cycle would be the most efficient. (Although we could swap anodes while careened at low tide, re-coating is a problem; we havent found a good prop paint that dries quick enough for this.)

We were not so concerned with finding the cheapest coating. Overall, we would prefer a more efficient hull, for both boat speed and fuel economy, than to try to make do with a cheap antifouling or try to extend time between treatments. As luck would have it, two of the four best coatings in this test were also lower-priced paints.

After our initial 18-month sea trial, we selected three of the tests top four coatings and again applied them to the boat. Based on the first trials results, these four coatings appeared to offer 18 to 24 months of protection, with a gentle wipe down every three months.

Interestingly, the three coatings that performed very similarly in the preliminary trial performed quite differently in the final coating trial. None were bad, but the best clearly stood above the rest.

Conclusion

Evaluating antifouling performance involves an element of subjectivity. We simply took a visual assessment, but it was clear that the four best paints from the preliminary rounds were appreciably better than the following four. The four best had virtually no fouling after 12 months, while the others had various degrees of fouling.

The boat test highlighted the importance of surface preparation. After about three months in the water, the International (Interlux) Micron 66 blistered (something that has never happened in our panel tests). The fault was ours-the primer we used was not compatible with Micron 66. The mistake would have been expensive if wed painted the whole hull.

The best four coatings were Internationals Micron 66, one of the recommended paints from our static trials in Florida; Jotuns Sea Quantum Ultra, which is based on a polymer jointly developed with NKM of Japan and designed to release biocide at a controlled rate; Resenes Altex No. 5; and PPGs ABC3, which is sold under the Ameron brand.

We found the best to be Jotuns SeaQuantum Ultra. This is the antifouling that Neeves has used previously on both hulls. The product is primarily marketed for commercial vessels worldwide. It is not approved in the U.S., nor is it approved for recreational use in some countries where it is approved for commercial use.

SeaQuantums advantage over the others was small, and we would be comfortable recommending the Micron 66, Altex No. 5, and ABC3 as well. Much depends on what is available locally as distribution and prices can vary in Australia or the Asia-Pacific region.

There are strict penalties in some countries for misuse of antifoulings, so caution should be taken when buying product, and one should ensure it is approved for recreational use.