Alot of water has rushed over the bridge since we last looked at synthetic teak decking materials—eight years worth. Since that last report (see “Synthetic Teaks Go Toe to Toe,” PS December 2015), we’ve subjected the same seven panels from that test to five years of weathering in the Florida sun.

We’ve also spilled wine, motor oil, and multiple cups of tea on them. We’ve tromped on them with muddy feet, bombarded them with a plumb bob, and pressure washed them—once—at 2,000 psi (see “How We Tested”).

Since the original report test, there have been a few changes in the market. Most notably has been the proliferation of color combinations, including glow-in-the-dark seams. One brand, Dek-King, has left the marketplace. One major manufacturer, Flexiteek, briefly doubled its five-year warranty in 2021, but then reversed course two years later. Several other new manufacturers have also entered the fray, including Teak Decking Systems, one of the world’s premier supplier of real teak decks for superyachts and cruise ships. We will be reporting on its synthetic products in a future issue.

Perhaps the most relevant event since that last test however, has been the ongoing restoration of the editor’s 1970 Yankee 30, which recently was stripped of all it’s deck paint and primer in order to prepare for new deck paint. This experience has prompted us to clarify a comment in our previous synthetic teak report that suggested that repainting a deck would be easier than a DIY plastic deck installation.

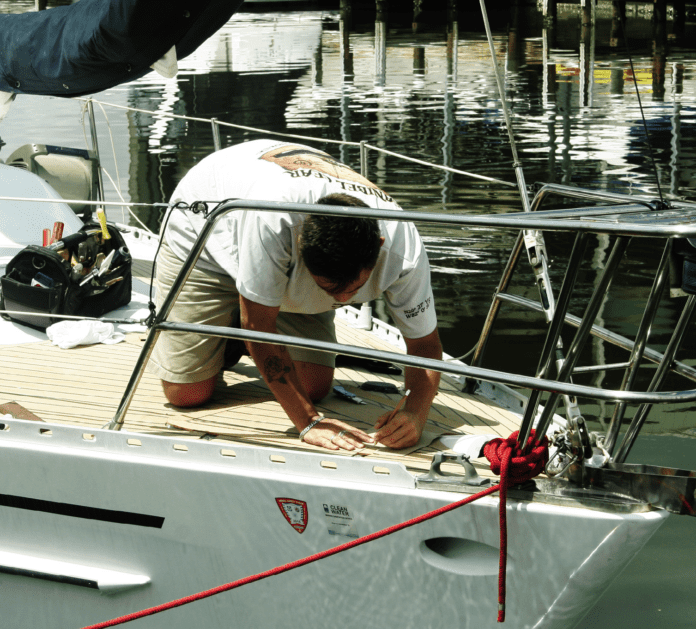

One week last year, as our beleaguered editor scraped and sanded away at the third of five layers of paint and primer (a project that would carry on for more than 30 days), he watched a two-person crew from one of the synthetic teak companies prep and re-deck a Beneteau nearly twice the length of Opal in three days—four if you include the measuring and computerized pre-cuts made before the installation.

DURABILITY VS. PAINT

As our last report on painted non-skid found (see “Non-skid 10 Years After,” PS November 2021), only about half the coatings—most of them two-part epoxies—were not significantly dulled by age. If synthetic teak can preserve its appearance past seven years, it could be a viable option, especially for heavy traffic areas like cockpit floors or foredecks where clanging anchors and chain can ding paint.

How well did the synthetic teaks hold up after five years? In two words, very good. None of the panels showed cracking, peeling, chipping or discernible fading. In fact, once we pressure washed them at 2000 psi (something you shouldn’t do with real teak), most of the panels appeared nearly as good as new. We weren’t surprised by the durability polyvinyl chloride (the material used in all but one of our test panels), a plastic that sadly can persist in the environment for decades.

All of the physical tests yielded nearly identical results to the original testing eight years prior. About the only thing worth noting was how constant wear exposed darker pigments in two of the panels—PlasDeck and Permateek. Initially we thought this was ground-in dirt or irregularities in the pigment, but with further probing, we realized that these striations gave the panels their grainy, aged appearance. Mild scrubbing returned these panels to their original look.

TEMPERATURE CONCERNS

With the durability question answered, the other questions that remain are cost, aesthetics, and temperature. Since we are based in Florida, the last item is the stickler for us. And there’s the rub, anyone who keeps their boat in warmer climates, or is bound for warmer climates, should be warned that just like the real thing, these synthetic teaks—even the lighter ones—can become too hot to walk or sit on in with bare skin summer.

Here’s a recap of our long-term test results, which have changed little since our initial report in 2015. Much of this information appeared in the original report, with some updating here.

WHAT WE TESTED

Practical Sailor tested five different brands of synthetic teak products marketed for marine use and sold in the United States. This is a very large field, so we narrowed our search to established players. Of those that we did not test, several seemed to be nearly identical to products we tested or they did not have a large share of the U.S. marine market.

Test results are shown in the accompanying Value Guide table. See “How We Tested” for details on the testing protocol and ongoing long-term testing.

DEK-KING

Manufactured by Wilks Rubber/Plastics in Tollesbury, U.K., Dek-King was available in five color combinations with black, gray, or cream caulking. Based on what we could find, Wilks now focuses mostly on rub rails, and has turned over its synthetic teak decking business to Flexiteek.

Bottom line: The product as we tested is no longer available. It did, however, hold up well in testing.

PLASDECK

Made in Akron, Ohio, PlasDeck is the only U.S.-made material in our test. The standard material comes in 32-foot rolls, either 2 inches or 6 inches wide with black, white, or custom caulking (blue, gray, cream, or a glow-in-the-dark material), and with straight or bullnose (rounded) edges. They offer dozens of caulking combinations, for both exterior and interior decking, and will design and install custom inlays, images, logos, and lettering.

The samples we received included three 24-inch by 16-inch panels in tan, gray, and light wood coloring. Testers found the PlasDeck material to be the thinnest and most flexible of our test samples.

PlasDeck sells its decking direct to do-it-yourselfers for about $18 per square foot, or they will provide pre-assembled sheets made from your boat’s deck template for about $35 per square foot; they also offer the option of having a local distributor measure, weld, and install the panels for about $65 per square foot.

Bottom line: Affordable pricing, and admirable durability makes PlasDeck our Budget Buy.

PERMATEEK

Manufactured in the United Kingdom, Permateek has 13 distributors throughout the U.S. and Canada. The company does not offer the product in strip form for do-it-yourself installers, but it will make custom panels from templates provided by customers. The kit comes complete with thermo-welded strips shaped to fit, adhesive, and instructions on gluing. All distributors offer on-site measuring, fitting, and installation service.

Permateek offers 14 color options—including traditional, weathered, and walnut—with black, silver, or white caulking. Pre-fitted panels range in price from $35 to $55 per square foot, depending on the complexity of the deck layout. Simple hatch covers or square swim platforms could be as little as $25 per square foot. The company recommends using Saba Sealtack 750 XL adhesive with the decking; each tube will glue about 15 square feet.

Like PlasDeck, Permateek began to show signs of wear after five years.

Bottom line: Based on our initial and long-term tests, Permateek earns a Recommended rating.

MARINEDECK 2000

Made by Stazo Marine Equipment in the Netherlands, Marinedeck 2000 is handled by several distributors in the U.S. The Florida-based firm MarQuipt covers the U.S. and Caribbean.

A company with a unique departure from the PVC material of its competitors, Marinedeck uses natural cork with a hybrid synthetic binder compressed under pressure. This results in a thicker, stiffer, and seemingly more durable panel that feels softer, stays cooler in the sun, exhibits good nonskid properties, insulates, and deadens sound. The material feels much softer under foot than the others in our test.

Marinedeck comes in a variety of sizes in 1/4-inch or 1/3-inch thicknesses, in sheets, or different width planks, with and without seams or caulking. The cost of planks and sheets, and seam-binder (minus the adhesive caulk) runs about $36 per square foot. The Marinedeck showed virtually no signs of wear after five years exposure.

Bottom line: Nonskid properties, feel, and durability give this a Recommended rating for those who care about thermal insulation properties and durability. For extreme hot or cold, this material is hard to beat.

FLEXITEEK

Flexiteek is headquartered in Sweden and sold in the U.S. by the Florida-based Flexiteek Americas. Flexiteek’s lighter, second-generation, material comes in 11 colors, including black. It’s sold in planks of various widths from 1½- to 4-inches wide. The PVC-composite material uses a heat-welding process to bond strips instead of glued caulking for long-lasting seams, according to the maker.

The Flexiteek surface feels medium smooth, with a look and feel very much like sanded natural teak. The company also offers matching composite material for toerails, rubrails, and various trim, edging, and angle sections.

In long-term testing, Flexiteek showed minimal signs of wear at the five-year mark. However, the company this year reduced its warranty from 10 years back to five years, suggesting that this is turning point in the

product’s life. Only Flexiteek panels sold in 2021 and 2022 carry the full 10-year warranty.

Bottom line: This widely available product is used widely on production boats. The standard version fell slightly behind our top finishers, but the lighter 2G version is worth a look for the weight conscious.

CONCLUSIONS

Permateek is grippy and resists staining and impact well, but Flexiteek maintained a more convincing grain and teak-like appearance.

PlasDeck, an affordable option made in the U.S., is still our Budget Buy for the do-it-yourselfer. Like Permateek, it fell a slightly behind Flexiteek in the reality game. Marinedeck earns a Best Choice rating for its cork-based material that resists stains, does not get too hot, and feels smooth to the touch.

All of the PVC products are very similar. Which teak decking substitute you prefer will depend on your preference of appearance and color combinations, your opinion on texture and appearance, and access to local distributor or installer.

CONTACTS

FLEXITEEK, 954/973-4335, www.flexiteek.com

MARINEDECK, 954/957-8333, www.marinedeck.net

PERMATEEK, 954/643-1380, www.permateek.com

PLASDECK, 800/320-1841, www.plasdeck.com

WILKS, 877/300-8024, www.wilks.co.uk

TEAK DECKING SYSTEMS, www.teakdecking.com

For this comparison of synthetic teak options, our first concern was ease of installation. The manufacturer typically carries out the hardest part—welding the panels together to achieve the correct dimensions. The ease of gluing our test panels to a simulated fiberglass deck was similar for all five test products. The difficulty of your own project will depend on how much work the manufacturer does in terms of measuring, assembling, and fitting the panels.

Material thickness and flexibility also were of interest. Each test panel was measured with a micrometer gauge giving thickness in decimal inches and checked for flexibility. PlasDeck was the thinnest and most flexible; Marinedeck was the thickest and least flexible; and the other three fell somewhere in the middle. Flexibility will affect the ease with which you can mold the strips or panels to the curves of your deck.

NONSKID

Perhaps one of the most important characteristics of a deck is its nonskid performance. We used the same homemade traction-testing jig that we use for testing shoe grip to gauge the test panel’s nonskid action when inclined at measured heeling angles. A Sperry Topsider deck shoe with a 4.5-pound weight was placed on each test panel, and the panels were raised at an angle until the shoe began slipping down the grade—wet and dry; the accompanying Value Guide shows the incline at which skidding took place.

The dent resistance test was revealing. We dropped a carpenter’s plumb bob with a pointed end from 6 feet and observed the holes made in each material, and then dropped an eight-pound mushroom anchor from 4 feet and noted any resulting dents. The natural teak fared worst, showing obvious puncturing and denting, even after 24 hours. Some synthetics that looked badly dented returned to normal after a few hours. Both Dek-King and the cork Marinedeck showed obvious holes and dents initially, but the blemishes smoothed out after a couple of days.

STAIN RESISTANCE

For the stain-resistance evaluation, testers soiled the panels with dirty oil, gasoline, coffee, and red wine, and rated the effects after 15 minutes and again 24 hours later, after cleaning with Palmolive dish soap and water. Harsh chemical cleaners or solvents, such as acetone or bleach, are definitely not recommended.

At the end of the five year test we cleaned all of the samples with a pressure washer using 10:1 dilution of Simple Green at 2000 psi.

DURABILITY

The biggest question mark for us was long-term durability. All of the manufacturers in our test offered five year warranties on the basic material and all of our panels lived up to the billing.

1. The dark striations used to simulate teak grain are clear in the Flexiteek and Permateek samples. The Permateek pattern is tighter and more regular. Permateek has broader irregular “grain” pattern.

2. After a quick powerwash, the right side of the PlasDeck panel looked very much like it did when we first tested it eight years ago.

3. Teak Decking Systems new synthetic decking includes a light color, but even that can heat up quickly in a warm climate.

4. The test panels spent much of their life on a dock in Southwest Florida.

VALUE GUIDE: SYNTHETIC TEAK DECK DURABILITY AFTER 5 YEARS

| PRODUCT | DEK-KING 2 | PLASDECK | PERMATEEK | MARINEDECK | FLEXITEEK 2G | NATURAL TEAK |

|---|---|---|---|---|---|---|

| COST / SQ. FT.* | $40 | $35 | $35 | $36 | $40 | $80 |

| FLEXIBILITY | Medium | Most flex | Medium | Stiff | Medium | Very stiff |

| THICKNESS | 0.223 in. | 0.176 in. | 0.205 in. | 0.352 in. | 0.212 in. | 0.621 in. |

| BOTTOM | Ridged | Smooth | Rough | Semi-smooth | Ridged | Rough |

| COLORS | 5 | 9 | 10 | 1 | 11 | N/A |

| TEST RESULTS | ||||||

| SLIP/DRY | 35 degrees | 37 degrees | 38 degrees | 35 degrees | 36 degrees | 36 degrees |

| SLIP/ WET | 32 degrees | 37 degrees | 38 degrees | 35 degrees | 34 degrees | 36 degrees |

| STAIN RESISTANCE | Fair | Good | Fair | Good | Fair | Very Poor |

| DENT RESISTANCE | Good | Excellent | Good | Fair | Good | Poor |

| PUNCTURE RESISTANCE | Good | Excellent | Excellent | Fair | Good | Poor |

| PRESSURE CLEAN | Excellent | Excellent | Good | Excellent | Excellent | Excellent |

| TEXTURE | Semi-smooth | Semi-rough | Semi-rough | Smooth | Semi-smooth | Rough |

We had 1″ thick real teak decking on our Hylas 49 for 10 years. Every year I had to go thru the process of cleaning it up, checking the seams, tapping for problems, putting on hundreds of dollars of sealer/tung-oil, etc… When we built our current boat (a Hanse 575) we moved to Flexiteek as we liked the look and anti-skid of a teak deck, but were growing tired of the work associated.

So far its been impressive. It looks like the day we took delivery, cleans up easily, has good traction, and was matched in one spot for a cockpit locker repair quite easily. I’m happy we made the choice.

That said, I don’t understand why a Flexiteek (or other) deck is often more expensive than a real teak deck. One might be less maintenance, but you would think incentivizing alternatives to harvesting teak rather than penalizing that choice would happen. Not so. This may be the boat manufacturers doing the old “make all the profit on the options” thing, so….