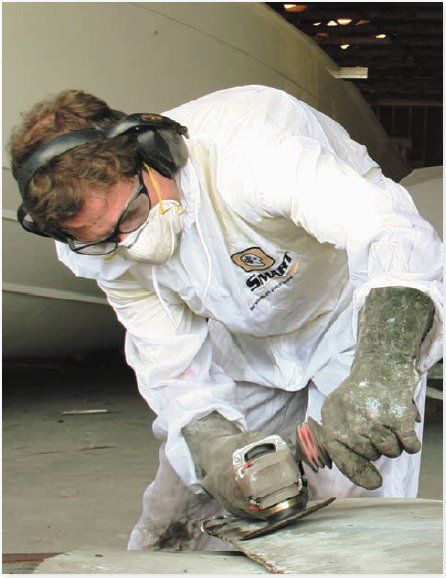

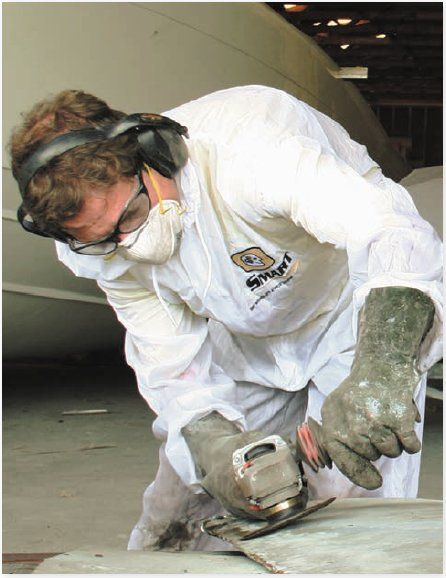

Although falling off a ladder or cutting yourself with a sharp tool are the most common boatyard injuries, damage from the foul air we breathe is more insidious. Marine paints contain solvents that can make you dizzy at best or increase cancer risk at worst. Dust from sanding wood is usually only a nuisance, but sanding bottom paint or grinding fiberglass presents serious health risks. Fortunately, there’s a wealth of industrial experience with contaminated air to draw upon, and by taking appropriate precautions, there is no reason working on the boat can’t be as safe as walking down the street.

Chemical risks can be identified by reviewing the Safety Data Sheet (SDS)-formerly referred to as the Material Safety Data Sheet (MSDS)-for the cleaners, paints, solvents, and other hazardous materials you’ll be using. A Google search under the product name and safety data sheet should bring up the information you need. Review Section 3 (hazards identification), Section 5 (fire and explosion data), Section 8 (exposure controls/personal protection), and Section 11 (toxicological information). Specifically, Section 8 identifies the appropriate respirator cartridge type, although not the respirator classification, since that depends upon the expected concentration.

Some dusts (sanding pine) are primarily a nuisance hazard and a dust mask can make it easier to breathe without coughing. Sanding bottom paint and grinding fiberglass require serious protection even at low levels. If the project is tented-common these days-the dust concentrations can require a half- or full face mask.

Finally, although this report naturally focuses on respiratory protection, exposure to the eyes and skin should also be considered. For example, muriatic acid (good for removing barnacles) splash and fumes present a danger to the eyes, particularly if you wear contact lenses. Fiberglass dust can easily sneak around most safety goggles and be irritating or damaging.

Select the Controls

The first line of defense is engineering controls. Can we reduce the exposure by changing the materials used, workplace methods, ventilation, or physically isolating the workers from the material? Is there a less toxic solvent? Can the material be removed by scraping instead of sanding or can a vacuum sander be used? Can ventilation reduce airborne concentrations below the need for protection? Failing this, respirators are the next step.

Air-purifying respirators can’t help with oxygen deficient atmospheres. Tanks, wells, and some bilges can be tightly sealed and often bacteria will have consumed much of the oxygen. A propane heater or torch can use all the oxygen in minutes. Ventilation is the cure. Air purifying respirators are not suitable for use in atmospheres that are classified as IDLH (immediately dangerous to life and health) due to either oxygen deficiency or high concentrations of toxic materials. Working in such environments is highly regulated, very specialized, and requires pressurized SCBA (self-contained breathing apparatus, similar to SCUBA) equipment.

Air-purifying respirators are also not safe for use with chemicals with very low exposure thresholds, poor warning characteristics (odorless, or inhibit the ability to smell), or impossible to filter. The most common boatyard example is the spraying of two-part polyurethane paints, such as Awlgrip; the isocyanate curing agents are too toxic, very sensitizing, and their warning characteristics are too faint. The practical solution is a supplied air mask, typically in the form of a full-face respirator with fresh air supplied by a compressor, similar to a diving hookah. The equipment is more expensive, but the cost of replaceable elements is eliminated. The Scott AV-3000 full-face respirator we tested is available with supplied air adapters.

Don’t overlook fire hazards. Every year someone has a flash fire when they decide that acetone or some other very volatile and flammable solvent is just the thing for stripping glue residue left behind by a failed ceiling lining. In a closed cabin, it only takes 1.3 ounces of acetone per 100 cubic feet of cabin to rise above the OSHAs limits-any higher is supposed to require continuous monitoring. To avoid this:

Remove spent rags as soon as possible or keep them in a sealed container.

Use only limited amounts of flammable liquids in confined spaces.

Ventilate, ventilate, ventilate.

Types of Masks

There are four types of respirator masks that interest the sailor.

Nuisance dust masks. These are not certified by NIOSH (National Institute for Occupational Safety and Health) and only good for harmless dust. Any dust mask should be NIOSH rated

NIOSH-rated dust masks. These have an Assigned Protection Rating (AFP) of 10, meaning that if properly fitted, 90 percent of the airflow should be through the filter rather than by leakage. Versions that have valves allowing humid exhalations to escape the mask are more comfortable in hot weather. The filter material can be rated as high as 95 percent removal (P95), but this is optimistic since these masks seldom maintain proper fit. As a result, the overall efficiency may be only 70 percent or less.

Cartridge Half Masks. The most common type of respirator, half-masks (AFP 10) allow the use of a wide variant of replaceable cartridges, fit better than fabric NIOSH masks and are compatible with goggles and eyeglasses.

Cartridge Full-Face Masks. Although much more expensive and not as comfortable in hot weather, full face masks (AFP 50) protect the eyes and lungs. On other types, fumes sneak past the seals and the eyes begin to burn. Full facemasks also provide a much higher level of fit reliability. OSHA rates full-face respirators as five times more effective in preventing leakage.

Full-face masks without mouth/nose cups are cheaper and may appear more comfortable, but they are prone to fogging. Masks with nose cups are designed to direct the intake air across the lens, keeping it clear, and reducing sweating. They also make it easier to breath, since exhale recycle is reduced.

If you use corrective eyewear, spectacle kits are available for fitting prescription lenses for $50-$100, plus the cost of the lenses. Far sighted people can modify a cheap pair of readers to fit. Remove the nose pieces, cut the bows to about 1 inches, tuck these inside the mask flange and duct tape the bridge to the nose cup. Self-adhesive lenses for dive masks also work, although these can limit the field of view. Contact lenses, although ordinarily unsafe around many chemicals and particulates, are acceptable within full-face respirators because of the improved vapor and dust protection.

Don’t assume organic vapor cartridges catch everything. Particulate filters are for dusts, organic vapor cartridges are for paints, solvents, and adhesives, and acid gas/chlorine cartridges are for bleach and muriatic acid. Combination cartridges that stack the filter elements to work with all three hazards can be a good value and a safe choice when the exposure may not be well understood and if you use the mask for multiple purposes.

Cartridge Filters. In an industrial setting it is common practice to slap in a new cartridge for each significant usage, but that gets a little pricey. For the occasional user, protect any cartridges that have been used but that you believe still have life remaining by keeping them sealed in a Ziploc bag, or better yet, a glass jar. If not, they will absorb any vapors available from the air during the year that passes until your next bottom job. If you are working with two-part polyurethanes that contain isocyanates, use a fresh cartridge at each use. When using chlorine bleach and muriatic acid, it is immediately obvious if the filter is failing.

Bottom paint sanding. The Occupational Safety and Hazards Administration (OSHA) has very strict exposure rules for copper dusts due to significant risk of respiratory, liver, and kidney disease. HEPA filters and full face or elastomeric masks are required for airborne levels between 1mg/m3 and 50mg/m3. Supplied air respirators are required between 50mg/m3 and 2000 mg/m3. If levels exceed 2000 mg/m3 only self-contained apparatus is acceptable. If you are power-sanding bottom paint use a sander with an efficient vacuum attachment and make certain your respirator is fit (see adjacent article) tested. Wet sanding will help keep the dust down.

Fabric Masks

Replace fabric masts after every significant use. They are inexpensive, and once the fabric begins to plug, bypassing and leakage around the edge increases. With an elastomeric mask you can wait until you feel some resistance with breathing hard.

Seafit Dust Mask

This inexpensive and widely available West Marine brand has poor filtration and poor fit. It is not NIOSH rated.

Bottom Line: In our view, these masks don’t belong in the boat yard. Save them for mowing the grass.

3M 8210/8210V

With improved materials and a better fit, these 3M masks are suitable for sanding and grinding in open-air situations. The V version includes a valve which allows humid exhale to exit there rather than saturating the material, making them considerably cooler than elastomeric respirators.

Bottom Line: Recommended for sanding in open-air conditions in hot weather.

Cartridge Half-Face Masks

These are preferred for most boat yard work, unless high concentrations or eye hazards suggest a full-face respirator. Again, match the cartridge to the job!

3M 6000 series

Perhaps the most common half-mask respirator seen around the boatyard, the 6000 fits a wide range of faces and is comfortable for hours at a time. Replacement cartridges are widely available.

Bottom Line: Best Choice for sanding, solvents, and cleaning.

North 7700 series

Made of silicone rubber, this half mask is less irritating to sensitive skin and offers a durable, more comfortable fit.

Bottom Line: Budget Buy for sanding, solvents, and cleaning.

MSA/Safety Works Xcel

Our tester used these in his home shop and around the boatyard for many years. It is slightly less durable that some others.

Bottom Line: Recommended for sanding, solvents, and cleaning in places with reasonable ventilation.

Scott Xcel Half mask #7421

This snug-fitting mask earned high marks for comfort and design. It has stood the test of time in our own workshop.

Bottom Line: Recommended for sanding, solvents, and cleaning with reasonable ventilation.

Full-Face Masks

Getting a stack of lens covers is smart if you will be spray painting or grinding metal; the lenses are too expensive to ruin. Sanding and working with cleaners do not require covers, but clean the lens carefully after use. Car or boat wax will keep paint from sticking to the lens.

3M 6900

Less comfortable and more leak prone for people with slim faces.

Bottom line: If you are going for a full-face respirator, you can do better.

3M FX FF-400

A professional quality mask, it fits well, has good field of vision, and lasts, but it is a little heavy and stiff compared to others.

Bottom Line: Budget Buy for sanding, grinding and solvent exposures at higher concentrations.

North 7700 A8

A professional quality mask. Our tester wore these for decades, during which they proved to be nearly unbreakable, and he tried hard. The silicone material makes them quite comfortable.

Bottom line: Recommended for sanding, grinding and solvent exposures at higher concentrations. Heavy duty.

Scott AV-3000

Known for their comfortable and reliable fit, these are among the lightest in the class. The unique mesh head harness increases comfort, speeds donning, and protects the faceplate (when not in use, fold the net over the faceplate).

An adapter is available for use with supplied air; our tester has spent days inside million-gallon diesel tanks performing inspections using this rig. Also nice for working with acid and bleach. The cartridge adapter can break if dropped hard.

Bottom line: Best Choice for acids and bleach, and for higher concentrations of solvents and dust.

Conclusion

Your first step should always be to reduce exposure. Use a vacuum sander. Use a different solvent. Ventilate. If more protection is needed, identify the hazard, select the appropriate a mask type, and select the correct cartridge. Make certain that the mask fits. As when buying shoes, the fit is far more important than price or style. If the mask does not fit (always test for fit), return it. Maintain your equipment so that its ready next time you need it.

Our favorites? If we need a mask at all, we like the 3M half-face masks, with a multi-function cartridge. When faced with a really nasty job-grinding inside the tent or using large volumes of bleach or muriatic acid-the Scott AV-3000 full-face respirator is comfortable, fits well, and with proper care should endure decades of occasional use.

I wear glasses, so I use a half face unit with a polycarbonate face shield when bottom sanding. Keeps the poison off my face and my glasses clean. I discovered that over time, that the half face with replaceable filters is cheaper than N95 disposable masks. The full face mask plus prescription lens would be a considerable investment when used only a few days a year.

For sanding ablative bottom paint with NO DUST, I use sheetrock sanding screens, a sponge or rag, two buckets for water and a bucket for sludge. I keep everything wet, I constantly rince the screen in a bucket of water. When bucket #1 gets too much paint in it I put it aside and use bucket #2 so the paint can settle to the bottom in bucket #1. When bucket #2 is goopy I pour off the water in bucket #1, put the sludge in the sludge bucket, fill bucket #1 with fresh water and let bucket #2 settle. And so on until I’m done. In the end I have a bucket full of sludge and a smooth bottom ready for the next coat of paint. No dust, no respirator, lots of goop.

Excellent suggestion. I will attempt this method first. we have old Ablative paint on our 41DS.

Extremely helpful article. Currently working on a 1974 Choate 37 deck refurb which has gelcoat worn down to fiberglass. Deck is enclosed by a canopy to protect other boats in the shed. Constructed a Corsi-Rosenthal box mounted mid-ship with additional filtration units in the stern and bow. Also invested in a r/o sander with dust collection and a double filtered shop vac. The N-95 mask I have been using works well but I think upgrading to the 3M 6000 series makes a lot of sense; especially when I move on to the finer grit papers. Will hopefully be rolling Alexseal later this Spring. Thanks again for the great article.

TKJ

What is the best 3M cartridge to use for bottom painting and gel coat repair?