The Get-Home Sailboat Tool Kit

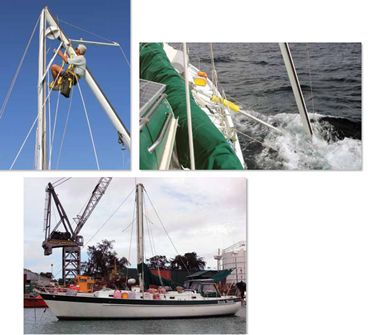

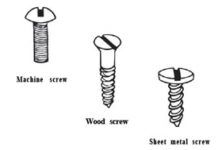

The tools and materials required to maintain and repair everything on a boat will barely fit in a room. Just the kit required to...

ITT Night Vision 260-A Star Among Night Vision Scopes

When the only thing that keeps you from going aground at night is an unlit channel marker buoy, a night-vision device suddenly becomes less...

Welds on Your Boat Require Special Care

The irregular shape of welds makes them difficult to inspect using ultrasound technology. Visual inspections can also be deceiving-especially with new welds. The prettiest...

Snap Extenders for Old Canvas

Sunbrella does not shrink. That is the mantra, and for covers and dodger that are left in place, it seems to be the true....

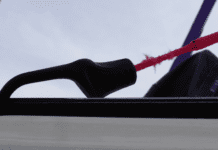

Shock Cord Hardware for Sailors

Every rope we have on board has its quirks when you’re trying to form a knot that won’t slip or come untied.

Dyneema is a...

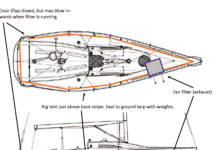

Making Your Own Workshop Filter

It all started when I needed to make a number of large cuts inside the house and outside of the confines of my shop....

Ralphs Great Adventures in Laminating

Technical Editor Ralph Naranjo equates spare time with boat projects. His basement shop/test facility has spawned a wide range of boats, boards, and parts...

Shurhold Shines Among Electric Buffers

Practical Sailors endless testing of hull waxes and polishes gives us ample opportunity to try out electric buffers. Weve used countless brands and types...

Durabak Nonskid Coating Long-term Test Update

In the January 2012 issue, we evaluated the application ease and traction performance of do-it-yourself nonskid options. A few months prior to the report,...