It all started when I needed to make a number of large cuts inside the house and outside of the confines of my shop. It was snowing outside, my wife was ill, and the project was in support of that illness and simply could not be delayed. I needed a high-volume dust filter and I had read some interesting things about people using HVAC filters to help cope with wildfire smoke inside their homes.

I had long wanted an exhaust fan for my shop, but the idea of pulling large volumes of heated or air conditioned air out of the house felt inefficient. The typical room HEPA filter cost hundreds of dollars and moves air at 100-200 cubic feet per minute (cfm). I wanted to turn over the room every few minutes, to really clear the air when sanding and sawing. My shop is about 250 square feet or 2,000 cubic feet. I needed something high volume.

The cheapest source of quality air filtration is high-efficiency HVAC filters, which are rated by MERV value. A higher MERV value represents better efficiency at removing dust. Filters rated at MERV 14 are a good fit for my purposes. A common filter used in homes, they are widely available. Higher efficiency filters would require either a stronger blower or a larger filter area.

Although even a MERV 16 furnace filter is not HEPA, it’s effective. Remember you’ll still be wearing an N100 fitted respirator for highly hazardous dust. A MERV 14 filter provides sufficient room filtration when sanding wood or fiberglass for painting (assuming you also have a vacuum connected to your sander and are wearing a respirator).

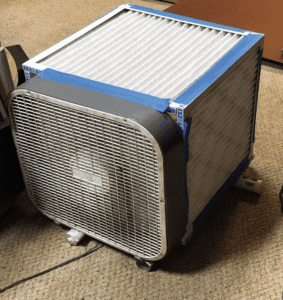

The cheapest high volume fan is a common box fan (about $20). They’re quiet and move air at about 2,000 cfm. Conveniently, they are also 20-in. x 20-in., which is a good match up to 20-in. x 20-in. MERV 14 furnace filters, which are commonly sold in six-packs.

The airflow of our DIY fan was 100-110 cubic feet per minute. You can slap a single filter (2.8 square feet) on your box fan and get 280 CFM, which is more than most portable room HEPA filters. But you can also tape five elements into a cube, with the fan as one side, creating 14 square feet of area and increasing airflow to a whopping 1400-1500 cfm. That’s enough to swap the air in my shop every 80 seconds and keep a large indoor work area dust free. The assembly is highly portable, weighing only eight pounds. Cut the tape on selected seams and it folds flat for storage.

To use it in my shop, I push it back into a reserved space on the floor, under a wall of shelving. The clean exhaust blows out the back, into an empty stairwell. This avoids creating a local draft and redistributes the air evenly throughout the shop. It is positioned low to catch maximum dust.

Duct tape is the standard recommendation for assembly. However, I used masking tape on my beta model, thinking I might change something (I didn’t). Because the vacuum pulls the elements together, the strength requirement is nil and though I added a few bits of duct tape later to fill some holes, the masking tape will clearly outlast the elements. It rests on 2×4 spacers to keep it off the floor so that all sides draw air. Every time I move it to a different workplace it gets rotated, so a different filter is on the bottom.

Originally, I intended to mount the filters in framework, but after using it for a while, I decided that would just make it heavier and bulkier. When this one clogs, I’ll just trash it and tape up a new one, though I may use duct tape next time, just because it it’s theoretically sturdier.

Could the fan be reversed, blowing through the filters instead? Certainly, because the pressure is low. Use duct tape all around and place two passes around the fan, just to be sure. Used this way. It could be placed over a deck hatch, sucking out dirty air.

How effective is it? I no longer sneeze after sweeping up or sanding wood. I can also do some welding without smelling up the house. (Not for welding stainless, which requires a much higher level of precaution, and has no place in a home setting). This filtration system won’t do anything with paint or solvent fumes; they require either air exchange or carbon absorption. Adding this capability to the DIY filter would make it very expensive, to the point of being impractical.

TENTING

Facing a messy combination of scraping, sanding, and grinding that a vacuum sander can’t manage? For a short job, buy a 10-ft. x 100-ft. roll of 4 mil plastic sheeting from the big box hardware store for $65. Reinforce the top edge with duct tape and a length of clothes line, and secure to the toerail or suspend some distance lower. Secure the bottom edge with boards or cinderblocks, and obviously, tarp the ground. Overlap the ends to form a door on the downwind side, and tape the fan/filter combo into the sidewall at the opposite end, to create a one-way draft.

This filter will change all of the air in the tent every 60-90 seconds for boats 35-40 feet long. That should keep the air clear and the temperatures down. Place the door and the filter in opposite corners and tape the filter into the tent. The filters go on the inside.

What do we use in our home furnace? We’ve been using MERV 12s for many years. The resistance is not too great, and a furnace fan has much greater pressure capabilities than a box fan. Logically, the ducts and heat transfer surfaces will stay cleaner, improving air quality and efficiency. If you are thinking about a true HEPA filter for home use, the pressure drop will be greater, and you will need either a higher pressure fan or a larger filter (reduced flow will reduce furnace efficiency and possibly cause overheating of the heat exchanger, although safeguards should prevent that). Old-school fiberglass furnace filters are less than MERV 1 and filter out only enough dust to keep the furnace from clogging up with junk prematurely, and they don’t do a great job of that.

High-efficiency filters, including high MERV filters, do need to be changed more often to prevent excessive pressure drop. If there is a solid grey coating on one side, it’s time.

Every home project that will stir up dust, as does every shop project—even when I sweep the floor. No more sneezing on pine sawdust. And boat yard projects are obvious enough. Even the flimsiest tent combined with a high-volume air filter and vacuum sander will keep your dust out of the air. Seasonal allergies? This DIY filter moves 10 times the volume of typical room HEPA filters.

This article was originally published on 18 May 2022 and has been updated.

Paragraphs 5 and 6 need reworked.

A standard box fan does not deliver 2000 cfm. The estimate provided in paragraph 6 of 100 to 110 cfm is probably closer, assuming no pressure drop.

Adding a filter will increase pressure drop which will reduce system cfm. Adding more filter area may reduce the pressure drop across the filter media, but will not increase the system air flow to an amount greater than the original fan rating.

Our test box fan delivered 2000 CFM without a filter in place, as measured by an anemometer. This is not untypical for box fans; Bob villa says 1100 to 2500 CFM is typical, depending on the speed setting. All values in the article were based on actual measurements.

There was one unit editing error. The measurement (not estimate) of 100-110 should have been in feet per minute, not CFM, which explains the correct figure of 280 CFM with a 2.8 square foot filter (100 ft/minx2.8ft^2=280 CFM). The rest of the figures follow and are correct. The 5-filter box fan does move 1400 CFM of air with fresh filters, as measured with an anemometer.

Please note; box fans are not spark protected. Do not use this assembly in a flammable atmosphere (ie any solvents, spray paint, etc.)

^^ Good point on spark protection. Not an issue for bottom sanding, but if using a box fan to ventilate a cabin while painting this needs to be considered. You would need to be either spray painting (not sure why you would do that inside a cabin) or using a massive amount of acetone to strip adhesive to generate enough VOC to reach the LEL with >1000 CFM of air moving. But consider it.

Four years after writing this (I always test things first) I am on my 4th set of filters, and I use them until they are coated and covered deep with gook. The shop stays cleaner. Less dust to interfere with painting, since the air is clear within minutes of sanding. My lungs thank me. My wife thanks me, since fugitive odors are reduced (not solvents, but dust, aerosols, and smoke are captured).