Every rope we have on board has its quirks when you’re trying to form a knot that won’t slip or come untied.

Dyneema is a dicey proposition. All but a few knots slip and it’s hard to cram enough stitching in to match the incredible strength of the fiber.

Polyester is easy to sew or knot. Stretch is minimal, allowing rows of stitches to share the load equally, and friction is sufficient to be secure with most knots.

Nylon is harder to sew, because it stretches and the stitches do not share the load equally (see “Stitching Instead of Splicing”). Many knots are impossible to untie after heavy loading, because the rope gets skinny, allowing the knot to tighten even more, after which the rope becomes fat again when unloaded.

But bungee is the worst of these. Knots like to roll or loosen during load cycling. Stitching through the rubber core is difficult, and seizings slide. Hog rings work pretty well, but they weaken the cord and only fit larger sizes.

Then there are the proprietary bungee clamps. Some cause chafe, others only hold the cord if the fit is perfect.

So, what approach is will provide the most security? The question is not just purely academic, since getting it right could very well prevent serious injury. Anyone who has had a near miss with a bungee hook that went whizzing by their eye when it let go can appreciate the importance of using right knot or terminal.

WHAT WE TESTED

We tested common knots and splicing methods on a variety of bungees ranging in size from 2.5 mm to 8 mm covered bungee cords. We also tested a few types of custom terminators. Many brands of shock cord were involved in the test (see “Shock Cord Test Looks at Long Life”).

HOW WE TESTED

We pulled both loops and bends until they either slipped or failed. Because the result varied depending on the size of the bungee cord and manufacturer, we haven’t present detailed figures.

More important are our general observations about which fastenings slipped easily, which worked loose with cycling, which held at working load, and which held until the cord broke.

We did not test proprietary clamps. We only tested bends between cords of matching diameter. Eyes were tested around blocks, which is more demanding that around a pin, because friction around the pin reduces the load on the tail. The eye attachment point has considerable impact on bungee strength because there is a lot more motion as the bungee stretches.

OBSERVATIONS

Recoil. Nylon can snap-back impressively when it breaks, but bungee is worse. A failed end or simply an over-stressed cord can take an eye out, so be careful. If possible, hold both ends of the cord and never pull beyond the elastic limit (the tension at which the cord suddenly becomes more difficult to stretch, as the cover begins to take most of the load). We’re focused on rigging applications, not tying down tarps or securing trash can lids against raccoons.

Strength. For most rigging applications, bungees are used to pull the slack out of rope tails, or at least pull them safely out of the way. Strength will never be tested beyond the elastic limit, about 20 pounds for ¼-inch bungee and in proportion for other sizes.

Safety. In actual use, bungees should never be used beyond their elastic limit, because UV damages the cover and failures come suddenly. If you have an application (securing gear for example) where high security and strength are required, use a reinforced bungee, like the Davis Industries Shockles.

KNOTS, SEWING, AND PROPRIETARY END CLAMPS

Some knots hold fine, some loosen under cyclic loading, and securing the tail is a good call. Stitching takes time but has proven dependable. Proprietary ends vary in strength. Some are stronger than the cord, some are likely to come off at any moment, even when lightly loaded.

EYES

Whether pulling a genoa car forward or securing a block against flopping, the most common requirement is a strong, low-bulk eye.

SEWN EYES

In 1/8-inch and smaller diameter cord, a single row of 8-10 basting stitches penetrating the core is secure. In larger sizes, a seizing at both ends to create a sailmaker’s eye adds security in larger sizes (see photo, right). Covering the stitching with adhesive lined heat shrink adds some durability and neatens things up, but in every test, the cord slipped within the tubing long before the cord reached its elastic limit because the cord shrinks under load and breaks the adhesive bond. Do not rely on the tubing to hold any portion of the load. Use the lower setting on your heat gun when shrinking tubing on rope or cord. The tube adhesives activate at about 220 F and nylon does not melt until about 500 F, it is possible to damage the cover if you are overzealous.

CRIMPED EYES

We expected to find reliable results, but most were disappointing.

• Jewelry and craft crimps. Often used on key rings as well as jewelry, these will not hold the cord up to its elastic limit. The materials are not corrosion resistant.

• Electrical butt-splice fittings. We tried these with or without heat shrink. Despite our best efforts to make a tight crimp, these failed at less than half of the maximum elastic extension. This is because the bungee diameter shrinks under load. The contraction also causes the adhesive seal to come loose.

• Aluminum cable crimp sleeves. These failed for the same reason as electrical crimps.

• Hog rings. We fitted at least two rings spaced about 1 line diameter apart. They squeeze the line tighter than crimps, reducing slippage. They can cause premature failure of the core due to excessive pinching. They can scratch the deck (cover them with heat shrink) and they are only available from ¼-inch up. They also slip short of the breakage point, but well beyond the elastic limit.

KNOTS

Knots don’t slip in bungee any more than nylon cord, but they can loosen or roll as the cord compresses.

OVERHAND LOOP

Notoriously difficult to untie in nylon rope, they hold pretty darn well in bungee if set tightly. However, the tail can creep in at very high load, so dress the knot carefully, pull it as tight as you can, and then secure the tail with adhesive lined heat shrink or a seizing. Not as secure on its own as the perfection loop, but we like that it is compact and the tail comes out parallel with the line. The bungee broke before the knot slipped.

PERFECTION LOOP KNOT/ ANGLER’S LOOP

Stronger than the overhand loop and does not require the tail to be secured. Little bulkier and only fishermen know this one, but it’s the best knot for bungee cord. Watch this step-by-step video on how to tie the knot.

BOWLINE

Do we really want a knot we can easily untie? A bowline will work, but, you must secure the bitter end close to the knot with a seizing, or tie a tight double overhand with the bitter end around one side of the loop. The result is a bulky, but strong knot, that you can still untie.

STRING OF HALF HITCHES

A string of half inches isn’t a pretty sight, but we found that three half hitches with the tail secured with a seizing or a double overhand knot around the working part is secure and easy to adjust.

CUSTOM TERMINATIONS

If you must have a hook there are commercial options, but be careful; some are much weaker than a good knot. Our suggestion is that you test one with full body weight before using.

SAILRITE SELF-LOCKING SHOCK CORD HOOK

We’ve tried these many times over the years. A sort of compression fitting with a locking collar, the cord must be an exact fit to hold anything. Cutting with a hot knife helps. The locking hook is hard to disconnect, so we usually cut them off. Fit perfectly, they fail at about the elastic limit of the cord, making them too weak for any high-load application (we tested ¼-inch and 3/8-inch).

SAILRITE SHOCK CORD HOOK, WITH CAM CLEAT (BY JALBERT)

The cord feeds through the center, and then back through a locking clam cleat. It takes a good tug to seat, so leave a 6-inch tail. They are reusable. These are strong, with the cord typically failing before the hook, but we had slips and hook failures.

COILED SPRING HOOK

In this common hook, the cord is secured inside the coil with either an overhand loop or a hog ring. In every trial, the cord failed first, though in some cases the spring uncoiled slightly, but without failing. The down side is scratching (see photos above).

J-HOOK

A plastic hook with a hole in one or two holes in the other end. If one hole, make a loop through it. If two holes, an adjustable lacing method applies.

CONNECTING TWO LINES

Among dinghy racers, common applications for bungee chords include pulling the slack out of control lines and pulling tails out of harm’s way. Our tech editor uses bungees to control the main outhaul and pull the shroud adjusters tails under the tramps of his Corsair F-24 trimaran.

INTERLOCKING EYES

Safest method with lines of differing characteristics (diameter, construction, or weave). The second eye can be a string of three half hitches; it looks messy, but it allows for slack adjustment as the bungee ages. Secure the tail with a lashing, a double overhand around the standing part, or even tape.

DOUBLE FISHERMAN’S KNOT

To make this knot hold, secure the tails with a lashing after completing the knot. You can also use a double overhand, or even tape to secure the tails. If the knot is highly loaded, it is best to untie it with a knife. This knot never slipped and tested about equal with interlocked perfection loops.

SPLICE TO ROPE

A splice is often the only way to feed bungee through a block or low friction ring. Pull out about 30 line diameters of core and trim with 10 diameters still exposed. Sew the core butt-to-butt to the bungee and milk the cover back over the cord (about 20 diameters inside). Place a single line of stitches down the center of the cord, starting about 10 diameters before the crossover. When you reach the end of the cover, seize the transition smooth. Since the line cover is stronger than the bungee, this is nearly full strength.

STOPPER KNOTS

Sometimes all you need to do is keep the cord from pulling through a hole. Light cargo bungees on kayaks are secured this way. Overhand knots aren’t much bigger than the cord once they are snugged down and can pull through worn holes. Figure eights can roll. The Ashley stopper knot is easy to learn, bulky, and stable. Leave the tail long or melt it into a substantial blob. Tighten it hard to make it stable.

CORD LOCKS

These are most commonly found on clothing, where the tension on a waist band, hood, or pant cuff requires frequent and easy adjustment. The holding power is minimal, but not much worse than some of the crimps because the spring adjusts for the contracture. They hold best when both ends of the cord are passed through. You can use two in a row for increased holding. They’ll corrode in a few years, so buy a bag and replace them. We use them on sail bags, ditty bags, hatch covers, grill covers, and kayak cockpit covers and deck cargo lines. They work with both cord and shock cord. Just be careful about how much hold you expect, and put stopper knots in the end of the lines.

CONCLUSION

Knotting and sewing bungee cord is challenging, but the rules aren’t totally different from rope. Knots that untie easily tend to be unstable during load cycling. When in doubt, secure the tail. With the exception of hog rings, connections that rely on pinching the cord failed sooner than others because the cord shrinks under high load.

Sewing is an excellent option when forming an eye or reinforcing a knot or clip. Heat shrink makes sewing neat and works well for securing the tails of knots. Overhand loops, the perfection loop, the double fisherman, and the Ashley stopper knots are the workhorses when joining or forming loops with shock cord.

VALUE GUIDE: SHOCK CORD HOOKS AND KNOTS

| TYPE | BRAND | MODEL | SLIP AT MODERATE FORCE | 3/16" BUNGEE FAILURE POINT (WORKING LOAD 8 LBS.) | PRICE |

|---|---|---|---|---|---|

| OVERHAND LOOP | — | — | — | 250 pounds | — |

| BOWLINE | — | — | — | 200 pounds | — |

| PERFECTION LOOP | — | — | — | 400 pounds | — |

| ELECTRICAL CRIMP W/HEAT SHRINK | — | — | < 5 pounds with 2 mm bungee | — | $0.40 |

| CABLE CRIMPS | — | — | < 5 pounds with 2 mm bungee | — | $0.25 |

| HOG RING EYE | — | — | — | Slipped at 150 pounds | — |

| SAIL MAKER'S SEWN EYE | — | — | — | > 400 pounds | — |

| DOUBLE FISHERMAN KNOT | — | — | — | 350 pounds | — |

| SHOCK CORD HOOK, SELF LOCKING | Sailrite | 370011 | 12 pounds (below elastic limit) | — | $0.70 |

| SHOCK CORD HOOK, WITH CLEAT | Sailrite (Jalbert) | 100297 | — | — | $1.40 |

| BARREL CLOSURE (CORD LOCK) | YKK | 3/16" | 4 (above elastic limit) | — | $0.40 |

| COILED SPRING HOOK | Various | 1/4" to 3/8" | — | 270 pounds | $0.26 |

| J-HOOK | Various | — | — | > 200 pounds |

Metal-free toggled bungees make fine sail ties, when snugly fitted. They are quicker to secure than ordinary sail ties and lacking a metal hook, they are free from corrosion.

Make a loop from the chosen shock cord using a double fisherman’s knot. Double the loop and slide a bits of heat shrink over each of the doubled loop and slide it up to the knot, so that there is one heat shrink tube on each side of the knot.

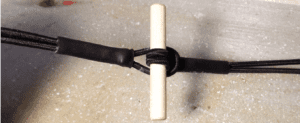

1. Cow hitch one end of the loop around a wooden toggle and seize tight with whipping twine (photo 1). The toggle should be twice the diameter of the bungee. The length should be 8 to 10 times the bungee’s diameter. Using whipping twine, seize an eye in the other end.

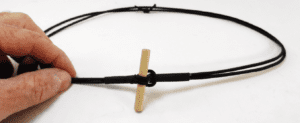

2. The eye should be just large enough to pass the toggle when it is folded flat against the bungee (photo 2). Slide the heat shrink over both seizing’s and shrink with low heat. Alternatively, both eyes can be formed with overhand loops and the heat shrink can be skipped. In this way, you can make several loops extremely quickly from a spool of shock cord.

3. Because the bungee is doubled at each end, the working tension of the loop will be four times the working tension of the single line, and double that of a loop made with the same bungee cord using only a single cord (photo 3).

It seems like a small thing—just a knot or a hook at the end of a bungee. But even we were surprised how many serious eye injuries result from bungee cord failures each year.

1. At 400 pounds, the sailmaker’s eye held, but the perfection loop knot/angler’s knot failed.

2. With the single hole style, the best attachment is a sewn eye. A perfection knot is a second choice.

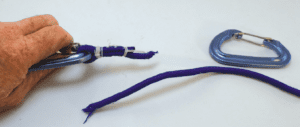

3. Jalbert hook and typical spring hook. Both very strong when used as designed.

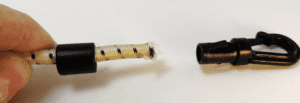

4. Self-locking hooks from Sailrite. These both came off, without warning, at about the maximum working load of the bungee. We do not consider these safe option.

Bungee cord, contrary to popular opinion, can be knotted, but you have to take special precautions. The common bowline, for example is bound to fail without taking the extra step of seizing the end.

1. This bowline looks secure.

2. But if it isn’t under any load, or springs back upon itself, it opens up.

3. The solution is to secure the tail close the knot with a seizing or other backup knot. It is still easy to untie, but it won’ untie itself.

This article was originally published on 11 August 2022 and has been updated.

Great and timely – replacing bungee cords on my sail, the part that holds my reef point cunningham down. Love PS…unbiased and rigorous tests. s/v Girlfriend

Great article, thanks Drew