In recent years, the popularity of absorbed glass mat (AGM) batteries has soared, yet few owners truly know how to take care of them. If you want to get your moneys worth out of a new AGM battery or battery bank, it should be installed as a system-not simply dropped in as a replacement for flooded batteries. [Ed. note: This article was updated with a subsequent article, AGM Batteries Test Update]

Battery manufacturers want their batteries recharged to 100-percent state of charge after each discharge. In reality, few cruising boats (or any boats kept on a mooring) return their batteries to 100-percent state of charge after each cycle. This typical battery use, or abuse, is called partial state of charge operation, and if it continues, a sailor can see his AGM battery perform noticeably worse than a less costly, deep-cycle flooded battery bank. This isn’t the batterys fault; it is just a lack of understanding of how to properly care for an AGM battery.

An often-overlooked ingredient in lead-acid battery care is equalization charging, which should be carried out periodically according to the manufacturers recommendations. During equalization, you apply a higher than normal charge voltage (15.2 volts to 16 volts) to a fully charged battery. Equalization can restore some lost capacity and also can serve to bring the individual cells to a better balanced specific gravity. In a 2008 Practical Sailor article, veteran cruiser Andy OGrady described how he used equalization to prolong the life of his heavily used wet-cell batteries (see PS October 2008 online).

Generally, equalizing an AGM battery is more complicated than it is with a flooded lead-acid battery (many AGM makers don’t even provide guidance on how to do this), so attaining 100-percent state of charge after each cycle becomes even more critical.

Last winter, we set out to try to solve the puzzle of AGM use and charging and to present a clearer picture of the permanent damage we are doing to our AGM batteries by keeping them in a partial state of charge. We chose AGM batteries for several reasons, but the main one was admittedly self-serving: They are easier to test.

Why AGM?

AGM batteries are lead-acid batteries. The chief difference is that they are valve-regulated batteries, in which the electrolyte is sealed, as opposed to wet-cell lead-acid batteries, which require you to maintain the proper electrolyte levels as the batteries are cycled. This reduced maintenance is one of the main reasons that AGM batteries are so popular.

The first step to testing a deep-cycle battery is confirming capacity. Battery capacity is measured in various ways: reserve capacity, cold cranking amps, and amp hours. We used amp hours, the most useful measure for comparing deep-cycle, house batteries meant for use on an average cruising boat.

In the U.S., amp hours are stated at the C20 rate, the constant rate of amperage that a battery can deliver for 20 hours, at 77 to 80 degrees, before the loaded terminal voltage falls to 10.5 volts (or 1.75 volts per cell). So, to roughly check whether your fully charged 100-amp hour battery meets its rated C20 capacity, you can apply a 5-amp load (100 20), and stop when the cells reach 10.5 volts. You should get close to 20 hours. (See How We Tested for a deeper explanation of determining capacity.)

Notice we said fully charged. In order to reach rated capacity, a lead-acid battery must be cycled several times and fully recharged. In addition, to fully recharge a lead-acid battery, more energy must be returned to the battery than was removed. For AGM batteries, this may range from 102 percent to as much as 115 percent of the removed energy being returned. As a battery approaches full charge, the number of amps it can accept tapers off. Short of counting how many amp hours you returned to the battery, an easy way to determine when an AGM battery is full is when the charge current at absorption voltage falls to 0.5 percent or less of the rated 20-hour capacity.

Notice we said absorption voltage. In order to reach a state of full charge efficiently, a multi-stage charging system is essential. The technical manual of the Lifeline battery we tested sums the multi-stage charging process this way: In the first stage, a constant current is applied until the battery voltage reaches a pre-set limit. The first stage is often called the bulk charging stage. In the second stage, the voltage is held constant at the same pre-set limit until the charging current tapers to a very low value, at which point, the battery is fully charged. The second stage is often called the absorption charging stage . . . The battery is fully charged when the current drops below 0.5 percent of the batterys rated capacity (0.5 amps for a 100-Ah battery). If the recharge does not return 102 to 110 percent of the discharged capacity, the batterys state of charge will gradually walk down as it is cycled, leading to premature failure. Therefore, it is important to verify that the battery is not being undercharged.

An AGM battery can cycle up to its maximum rated amp-hour capacity quickly, usually in just in three to seven cycles. This makes life easy for testers.

Flooded batteries, depending upon type, can take 20 to 150 or more cycles before they reach the factory-rated amp-hour capacity. Because flooded batteries take so long to cycle up to capacity, this makes testing them very difficult, and extremely time consuming.

Fighting Sulfation

Sulfation is the enemy of all lead-acid batteries: AGM, gel, and flooded. Think of sulfation as an unavoidable disease, and a healthy charging regimen as treatment. All lead-acid batteries will sulfate. Treating the batteries correctly helps reduce sulfation and leads to longer battery life. Unfortunately, sailboat batteries rarely get the treatment to hold off the sulfation long enough to achieve a desired cycle life.

As a lead-acid battery discharges, lead sulfate forms. As the battery recharges, this lead sulfate is reconverted to lead and lead dioxide. In a perfect world, all of the lead sulfate would reconvert with each full charge cycle, but some lead sulfate never reconverts. Instead, it slowly hardens into lead-sulfate crystals and becomes permanent. The longer you go between full charge cycles and the deeper you discharge your battery, the more hard-lead sulfate you leave on the battery plates. This process reduces the amp-hour capacity that the battery is capable of delivering.

For this test, we wanted to see just how fast the effects of sulfation could set in and damage brand-new, healthy batteries. To do this, we turned to a partial state of charge cycle test.

A partial state of charge cycle test is testing in which the battery is discharged and partially recharged but does not return to 100 percent before being cycled again. This mimics what happens when were at anchor or when we store our boat on a mooring or in a marina with no electricity. In these cases, partial state of charge operation is a fact of life-a fact of life that can be murder to batteries.

Even the most sophisticated sailboat alternator and regulator will not regularly get your batteries back to 100 percent. Most sailors don’t, or wont, run the motor long enough to get there. Charging batteries to 100-percent state of charge, even with AGMs, takes upward of six to eight hours or more. As sulfation sets in, this time grows even longer. The effects of sulfation are cumulative.

As far as we know, this is the only test of AGMs that has looked at the effects of partial state of charge use as related to the way we use our batteries on sailboats.

After bringing the batteries up to full charge and defining amp-hour capacity, we cycled them 30 times through partial states of charge, applying just one hour of recharge, and we charted the results. (For details on our test, see the accompanying How We Tested.)

What We Tested

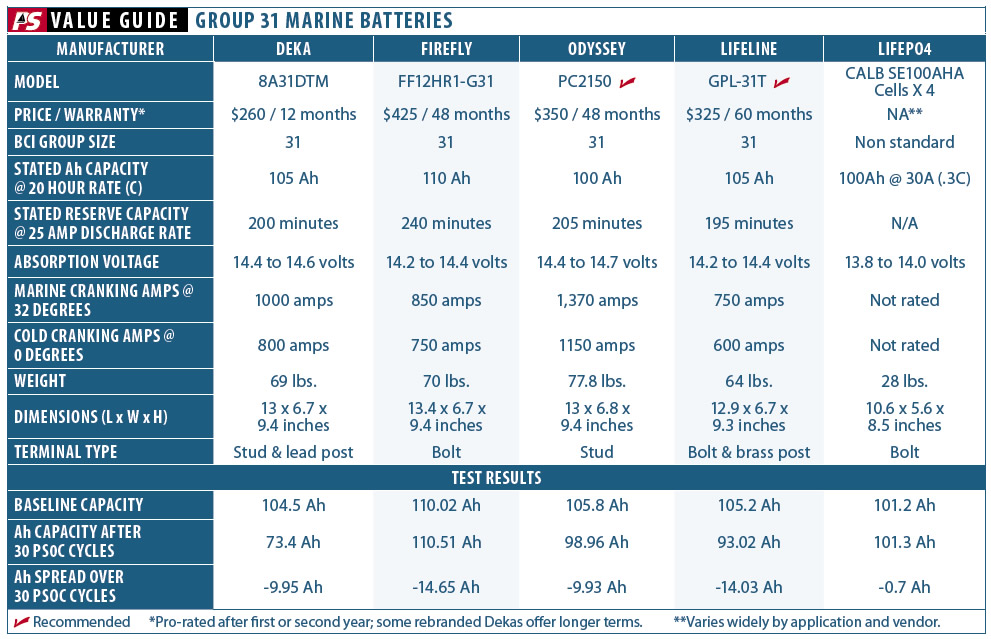

We selected three of the most popular marine AGM batteries and two new-technology AGM batteries to run through our partial state of charge testing. Considering this testing took many months to complete, we focused on the most popular AGM batteries, in the Group 31 size. Many battery vendors actually sell the same battery, privately labeled, and because testing was so time-consuming, we wanted to avoid duplications. With rated capacities of about 100 amp hours, Group 31 is the size commonly found on an average 30- to 40-foot cruising boat. Heres what our roster looked like:

Lifeline GPL-31T (105 Ah): The Concorde Battery Co. manufactures Lifeline batteries, a longtime player in the marine market. It is one of the most popular AGM batteries in use on boats today.

Deka 8A31DTM (105 Ah): East Penn Manufacturing in Pennsylvania manufactures and markets the widely distributed Deka brand batteries. This battery appears under many different labels. East Penn has a state-of-the-art recycling plant for used batteries.

Odyssey PC2150 TPPL AGM (100 Ah): Marketed as a dual-purpose battery, this thin-plate pure lead (TPPL) battery is made by EnerSys, based in Reading, Penn. This battery is also currently sold as the Die Hard Platinum AGM.

Firefly Oasis Marine Group 31 (110 Ah): Featuring materials and a design that is relatively new to the recreational marine market, the Firefly Oasis uses a patented carbon microcell foam technology that the company claims can delivery longer life and better performance under extreme conditions. The Firefly Oasis Marine AGM is distributed through Bruce Schwab Energy Systems.

China Aviation Lithium Battery Co. (CALB) SE100AHA LiFePO4 (100 Ah): This is a lithium-iron phosphate battery (LiFeP04), sometimes abbreviated as LFP. It is not a drop-in replacement for a lead-acid battery, and it is not recommended for the typical consumer. Mastervolt, Genasun, and Victron build factory-ready LiFePO4 systems, and these would be good places to begin any investigation into a LiFePO4 system for marine use.

Others: Northstar/Energy 1 sent us a battery, but it arrived too late to be included in this round of testing. It will be tested alongside a duplicate Deka battery for comparison and to verify results with the Deka battery we used for this test.

What We Found

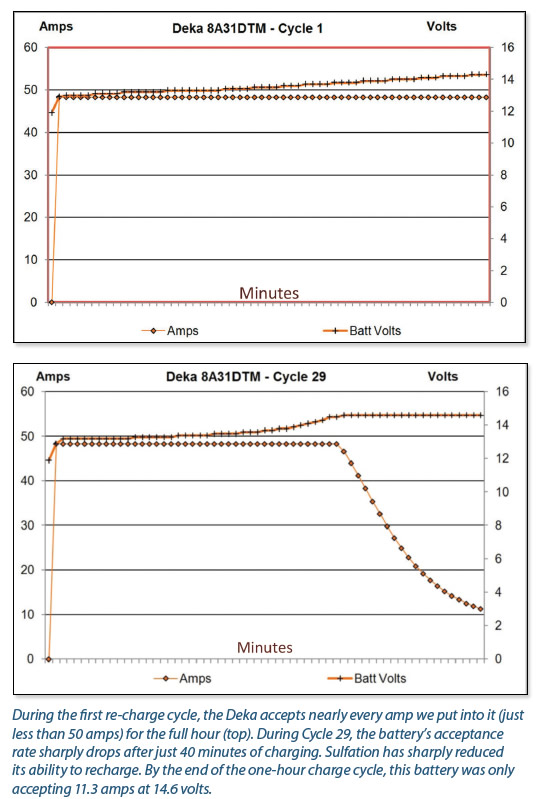

AGM batteries accept lots of current in bulk charging, and this can be a real advantage for cruising boats that want to benefit from short high-amperage charging cycles. However, chronic partial state of charge results in sulfation, and this drastically shortens the amount of time the battery is capable of accepting bulk charging.

AGMs are, in one sense, a Catch 22. You paid more for an AGM battery for its fast charge acceptance rate, and shorter engine or generator run times, but if you continue this partial state of charge operation, AGM batteries begin to behave more like flooded batteries in terms of their charge acceptance rates. And while a flooded batterys capacity can often be partially restored through equalization, the effects of partial state of charge are often permanent in AGMs.

What was striking in our tests was the speed at which the AGM batteries began walking down when put through partial state of charge conditions. On the first charge cycle, every single AGM battery we tested took the full charge rate (46 percent of amp-hour capacity) for the entire hour. The batteries remained in the bulk charging stage for the entire hour, allowing for very efficient charging. By the second cycle, some batteries were already beginning to walk down, and were attaining the absorption voltage by the end of the hour. Within a few cycles, all of the AGM batteries were attaining absorption voltage near the end of the one-hour recharge. With each successive PSOC cycle, absorption voltage was attained earlier and earlier in the short one-hour charge cycle, and the batteries began slowly walking down. This walking down effect in usable capacity was caused by sulfation.

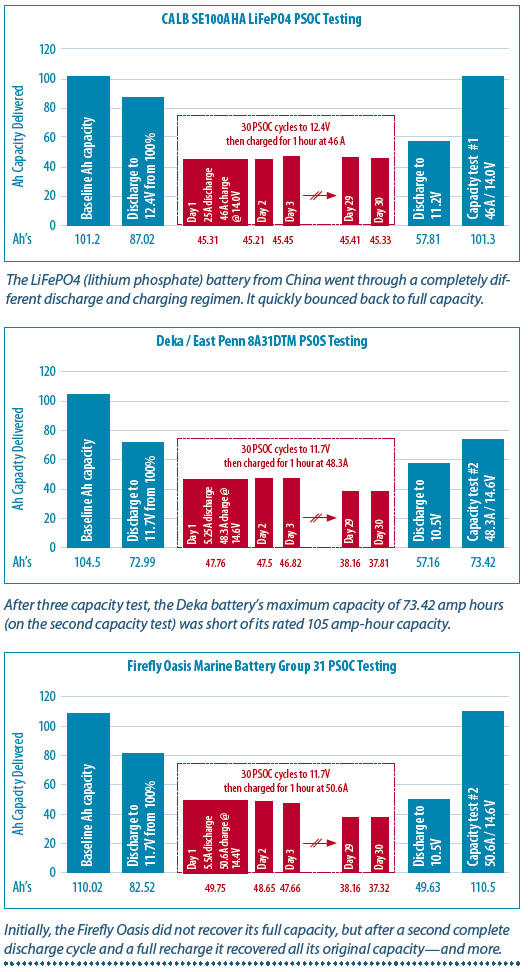

It was interesting to see how the LiFePO4 battery capacity did not diminish through the course of our testing. The reason is clear: LiFePO4 does not sulfate. This testing shows why you need to fully recharge AGMs as often as possible.

As the accompanying tables indicate, when a sailor recharges his battery for one hour each day (at an assumed 80 amps from his alternator), he is not charging as his battery as fully as he might think. Under this regimen, all of the AGM batteries lost usable capacity, from the one-hour recharge from cycle No. 1 through cycle No. 30. If we look at the spread between the highest to lowest losses in usable capacity, in amp hours, on all the batteries over the 30 cycles, it looks like this:

Firefly: 49.75 to 35.10 = -14.65 Ah spread

Lifeline: 45.56 to 31.53 = -14.03 Ah spread

Deka: 47.76 to 37.81 = -9.95 Ah spread

Odyssey: 44.69 to 34.76 = -9.93 Ah spread

LiFePO4: 45.74 to 45.04 = -0.7 Ah spread.

Note that the highest to lowest was not necessarily beginning and end. Some batteries bounced up and down, so highest-to-lowest, one-hour recharge usable capacities were simply taken at the highest and lowest usable capacities over the 30 cycles. The complete set of tables indicating all 30 cycles are available in the online version of this article.

Firefly Oasis Carbon Foam

The Firefly Oasis Marine Battery is rated as a 110-amp hour battery, and for our test, it started at 110.02 amp hours. On the first PSOC cycle to 11.7 volts, the batterys usable capacity was 49.75 amp hours. The Firefly then walked down and hit a low point of 35.1 usable amp hours at cycle No. 21.

The Fireflys usable capacity bounced up and down more than other batteries in our testing. The lead engineer at Firefly suggested the peaks occurred after the battery remained at absorption voltage slightly longer.

At the end of 30 cycles, we conducted the first capacity test (discharged to 10.5 volts and then recharged to 100 percent, see How We Tested), and the battery delivered just 94.03 amp hours, a loss of nearly 16 amp hours in capacity from the original baseline. This was disappointing, especially for a battery that claims to resist sulfation. Fireflys lead engineer instructed us to try another capacity test. Indeed, after a second discharge-recharge cycle, the battery not only regained all its capacity, but increased slightly (by 0.5 amp hours) to 110.5 amp hours.

Ultimately, the Firefly lived up its makers claims. In just a few deep cycles, with full recharges, these batteries can regain most-and in some cases all-of the lost capacity due to partial state of charge cycling. The battery required back-to-back deep cycles, both with 100 percent full recharges, but it worked.

Bottom line: Although this AGM technology is still new to the recreational marine market, it is certainly something to watch for in the future.

Odyssey PC2150

The Odysseys maker, EnerSys, was the inventor of the orbital battery technology (Optima) and is well ensconced in the military, aerospace, and backup battery systems markets. The Odysseys thin-plates pack more plate surface area into the same space as other designs, enabling it to provide both very high cranking power cranking pulses and longer life.

It sounds counterintuitive that a thin plate battery can be used for deep-cycling applications, but the Odyssey TPPL AGMs have a strong following. The PC2150 is a Group 31 TPPL AGM battery rated at 100 amp hours. This particular battery tested above its rating with a baseline capacity of 105.8 amp hours.

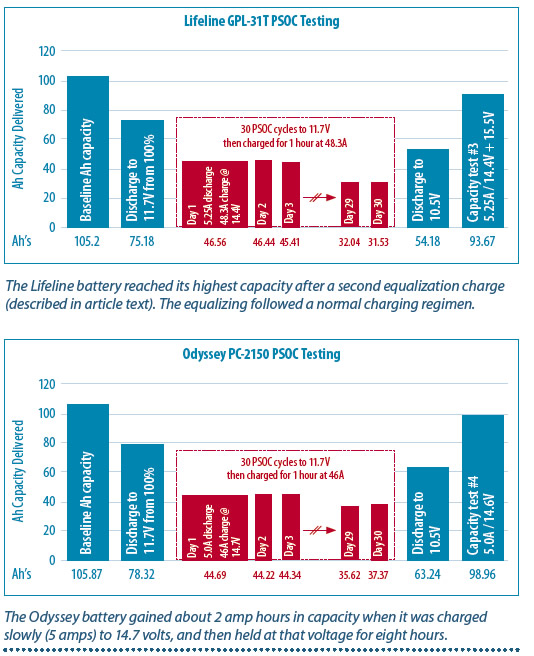

The Odyssey walked down a little slower than other batteries and did not dip as deeply at the end of 30 partial state of charge cycles. At the end of the partial state of charge capacity testing, however, the PC2150 could not get back to its baseline as-new capacity. It started life at 105.8 amp hours, and after three capacity tests, it delivered a high of 98.96 amp hours. For testing purposes, this represents a capacity loss of approximately 6.7 percent, but if we consider its rated capacity of 100 amp hours, it only lost a little over 1 percent. The final capacity test on the PC2150 involved a recharge at the 20-hour rate of 5 amps. The battery actually gained 2.17 amp hours when charged slowly at 5 amps to 14.7 volts and then held at 14.7 volts for eight hours.

Bottom line: Overall, the Odyssey handled the partial state of charge cycling fairly well, and the higher absorption voltage (14.7 volts) seemed to help minimize capacity loss.

Deka / East Penn 8A31DTM

The Deka /East Penn 8A31DTM is a hybrid, dual-purpose AGM battery. Widely distributed under many different brand labels, this is perhaps the most popular AGM battery on boats today. This particular battery is sold by Deka, West Marine, NAPA, many Sams Clubs as a Duracell, OReilly Auto, Power-Tec, MK Battery, and under numerous other smaller labels. It is one of the least expensive AGM batteries you will find on the U.S. market. Some labels offer better warranties, so it can pay to compare.

The 8A31DTM is rated at 105 amp hours. This particular battery tested slightly below its rating with a baseline capacity of 104.5 amp hours. Netting 104.5 amp hours from a 105-amp-hour battery is certainly acceptable.

The Deka 8A31DTM walked down at a reasonable pace compared to others during the partial state of charge testing, and handled the partial state of charge cycling well. Its lowest usable capacity, after the one-hour recharge during the 30 PSOC cycles, was higher than that of all the other lead-acid batteries, meaning it walked down slightly less.

At the end of the partial state of charge testing, however, the 8A31DTM had lost a large percentage of its original 104.5 amp-hour baseline capacity. Even after three capacity tests, the 8A31DTM could only deliver 73.42 amp hours. This represents a surprisingly high capacity loss, during the partial state of charge testing, of approximately 30 percent of its as-new tested capacity.

Bottom line: Deka suggested that our test did not bring the battery up to full capacity prior to capacity testing. We worked closely with Dekas tech team to bring the battery to full capacity, so this seems unlikely, but to confirm whether our particular battery was an anomaly, we will be testing a second Deka battery. The decline could be inherent to the Dekas intended dual-purpose design, but we can’t really be sure until we test a second battery.

Lifeline GPL-31T

The Lifeline GPL-31T is a deep-cycle AGM Group 31 battery that, as far as we know, is not privately labeled. The manufacturer, Concorde, has a long history of providing batteries to the recreational vehicle market as well as to many of the top-tier boat builders. The company is known for its robust build, excellent tech support, and the willingness to stand behind the product.

The GPL-31T is rated at 105 amp hours, and this particular battery tested slightly above its rating with a baseline capacity of 105.2 amp hours. The battery walked down at a bit steeper pace than others during the partial state of charge testing, but it has a secret weapon that other AGMs do not. The Lifeline can be equalized, or as Lifeline calls it condition charged, when needed.

To condition charge a Lifeline AGM, you can apply a temperature-compensated voltage of up to 15.5 volts for as long as eight hours. At the end of the partial state of charge testing, the GPL-31T had lost a bit of its original 105.2 amp-hour baseline capacity. On the first capacity test, the battery turned in a capacity of 89.43 amp hours. For the first capacity test, we charged it at 48.3 amps and 14.4 volts until current was at 0.5 amps; we then ran a 24-hour float charge voltage; and finally let it rest for 24 hours disconnected. (The Lifeline AGM charges at a lower absorption voltage than the Odyssey or Deka.) We then ran the same recharge cycle, but once the batterys acceptance hit 1 amp at 14.4 volts, we adjusted the voltage to 15.5 volts for four hours, then floated and rested the battery for 24 hours. This bumped up the capacity to 91.21 amp hours. Noting an increase in capacity, we did the same thing again. After that condition charge, the battery bumped up to 93.67 amp hours.

Finally, we went back to the standard charge protocol of 14.4 volts to 0.5 percent acceptance and retested. This time, the battery dropped back slightly to 93.02 amp hours. This was the only battery that got a fourth capacity test, which we performed only because it had these special charge capabilities, which our testing confirmed, does seem to work. Eight total hours at 15.5 volts over two consecutive back-to-back capacity test cycles yielded a small but definite improvement of almost 4.25 amp hours in regained capacity.

Bottom line: Overall, the Lifeline lost nearly 11 percent of its as-new capacity in the 30 partial state of charge cycles. The condition charging helps, but might need to be done more often in a heavy PSOC cycling application. It would be best to consult with Lifeline on this.

CALB SE100AHA LiFePO4

We included this battery to see how it did against lead-acid in a partial state of charge test. This battery consisted of four CALB SE100 prismatic LiFePO4 cells (LFP) wired in series. This is not how LFP batteries would be installed on a boat; we did this only for testing purposes in a very controlled environment.

LiFePO4 batteries perform differently from lead acid but should also charge at lower voltages, closer to gel or below (13.8 to 14 volts is ideal), and unlike lead-acid batteries, you don’t want to float charge LFP batteries. LFP batteries also have considerably higher resting voltages than do lead-acid batteries. A pack like this, under normal house loads on a boat, would rarely dip below 13.2 volts.

This battery was not discharged or charged based on a 20-hour rate. LiFePO4 batteries have a minimal Peukert effect, so drawing them at a low current wont really yield much more capacity. (According to the Peukerts Law, as the rate of discharge increases, the batterys available capacity decreases.) For this reason, LiFePO4 batteries are rated at a specific discharge load, not time and discharge load like AGMs. Most makers rate LiFeP04 batteries at 30 percent of capacity (.3C), as is shown in our table.

This 100 amp-hour battery was discharged at 25 amps and charged at 46 amps. We discharged it to approximately 86 percent depth of discharge, far more than we did with the flooded batteries. The widest gap in capacity during the 30 partial charge cycles was just 0.7 amp hours. If wed counted amp hours instead of using a cut-off voltage to determine when to stop charging, this small variation would likely disappear.

This battery tested at 101.2 amp hours after we manually balanced the cells. After 30 partial state of charge cycles, the LiFePO4 battery tested at 101.3 amp hours, showing effectively no loss in capacity. This is what LFP batteries do best, partial state of charge cycle.

Bottom line: LiFePO4 batteries are still expensive, and dropping an LFP into a lead-acid charging system can lead to expensive and possibly dangerous problems. Given time, LFP will be a contender, but today, it remains out of reach of all but the very technically inclined sailor, or one with deep pockets.

Conclusion

The results of our test were clear: The longer any lead-acid battery is left at less than 100 percent state of charge, the more permanent harm sulfation is causing to the battery. Except for the Deka battery (which we will be retesting), these batteries generally lived up to our expectations.

Because of small variables in production lines and distribution (shelf storage times and maintenance can also impact performance), a single test is not enough for us to pick an overall winner between the Odyssey or the Lifeline, the two mainstream batteries in our test. Both are equally capable of meeting a sailors house bank needs. We did not evaluate cold cranking (starting ability), something the Odyssey claims to excel at. The Firefly topped both of these in terms of recovering capacity, but because we have so little data from the marine market on this product and the support network is unproven, were hesitant to enthusiastically jump on the Firefly bandwagon. We intend to followup with some field-testing. Stay tuned.

Keep in mind that the abuse that our test batteries endured is less harmful than what commonly occurs on our boats. It can be even more damaging to leave a battery to stand at 50 percent state of charge, for multiple days, than to conduct multiple back to back 100-

percent discharge capacity tests followed by a full 100-percent recharge.

Heat is also a major factor in overall cycle life. A worst-case scenario would be a sailboat with only an alternator for charging that anchors or moors in an area where the batteries remain above 80 degrees. (Bahamas, anyone?)

Boaters on moorings or docks with no charging capability other than the alternator should consider an alternative means to get the batteries back to 100 percent state of charge as soon as possible after each discharge. Even a small 20- to 60-watt solar array with a charge controller can greatly extend battery life for a boat without shore charging capability.

In the accompanying sidebar Tips and Techniques, we offer guidelines to help prolong battery life, but basically, it boils down to this: Do your best to get your batteries back to 100 percent state of charge as often as is possible, using your manufacturers prescribed voltages, and your batteries will thank you.

What was the result of the 2nd test of the DEKA?

Hi KC,

Here is the follow-up. We’ve also added a link in the text.

https://www.practical-sailor.com/systems-propulsion/electrical/agm-batteries-test-update

Darrell

What a fantastic piece of battery information, the best info ive found on AGM batts & sulfation. Well done & thanks for posting it .

Greetings, thanks for all your elaborate testing! I have a 2017 diesel motor home. I have 4 US AGM L16 6VDC batteries. I installed the these as they discharge very little gases! As they are in a compartment with a lot of exposed components, that would be susceptible to corrosion! My question is about using solar while dry camping as a means of maintaining full battery SOC? I only have 480 watts of solar. I do use my generator when needed when using a high amp draw like our microwave. So what information can you give me on using solar. Also I use a go power system for managing the 30 amp system. I see your information is directed for marine use & I hope my question isn’t out of your testing!!

Thank you

Dave