Beginning in March 2014 with a review of wind sensors, Practical Sailor embarked on a series of articles on wind instruments. The series kicked off with a look at mechanical, mast-mounted sensors (see PS March 2014 online); Part II compared the various ways that wind data is computed and displayed (see PS May 2014 online); and Part III sought to find the ideal system, matching sensors and displays from different brands (see PS August 2014 online). The ink had hardly dried after the first round of testing, when readers began asking about ultrasonic wind sensors, which appear to offer a number of advantages over conventional mechanical sensors and their revolving-cup sensors.

The redeeming features of ultrasonic wind-sensing are many: no spinning cups, no wind vanes for birds to perch on or fly off with, and no discernible moving parts. This is not new technology. Ultrasonic devices are used for focusing a camera, taking pictures of a fetus inside the womb, doing non-destructive testing, and taking liquid level measurements. From the sailors viewpoint, ultrasonic sensors are compact, lightweight, easy to install, and very accurate.

In the U.S., there are two principal suppliers of these sensors, Airmar and Maretron. We featured sailor Dan Corcorans upgrade to an Airmar PB200 wind sensor in the September 2013 issue. Now, with this article, we look at the Maretron WSO 100.

One notable feature of the WSO 100 is that it operates on the NMEA 2000 (N2K) system; many older boats still operate with the older NMEA 0183 system. If your boat is not equipped with the cabling required by N2K, you will want to read Corcorans report, which also gives a sense of the wiring challenges and payoffs of an upgrade to N2K. Assuming youll want to put the sensor on the top of your mast, any wiring upgrade will require running new wires inside the mast.

According to Stan Honey, a technical innovator who was intimately involved in last years Americas Cup, the Cup teams are using ultrasonic sensors near the water level. However, at the masthead, where there is lots of upwash, extra weight is abhorred, and where speed of response is important, sailing teams have found the cups and vanes to work better. Using analog sensors (similar to the NKE HR sensor we tested) wind-angle within a fraction of a degree is possible, he said.

What we tested

For this report, testers compared Maretrons WSO 100 to the mechanical sensors from Part I in our series. We hope to look at other devices, including another evaluation of Airmars sensor in a future report. In addition to providing apparent wind speed and wind angle, the WSO 100 also measures air temperature, relative humidity, and barometric pressure. It can be paired with one of Maretrons displays-such as the bright and compact (2.7 inch by 3.7 inch) DSM 150 ($495) or the multifunction DSM 250 ($995)-or any other N2K display.

How we tested

We followed the same test protocol with the Maretron WSO 100 as we did with the mechanical sensors in the March 2014 report. The sensor was installed as directed by the manufacturer on a 4-inch-by-1-inch diameter antenna pole mount. We checked accuracy in various configurations using our home-built, low-speed wind tunnel. The recorded wind speeds were compared to those taken with two handheld wind-speed anemometers in the same location. We then tilted the wind sensor to 45 degrees to simulate the angle of a boat when heeling, and observed how this affected recorded speed and wind direction. The unit maintained accuracy past the makers specified 30-degree heeling angle. Barometric pressure and ambient temperature were compared with calibrated readings from a Garmin Quatix watch (see PS August 2013).

We placed the Maretron WSO 100 at the center of the wind tunnel, at a distance of 1 foot from the face of the wind tunnel, where wind speeds were as low as 1 knot and as high as 6 knots. We found the Maretrons wind flow measurements to be accurate within 0.2 knots, matching the accuracy of our best mechanical sensors.

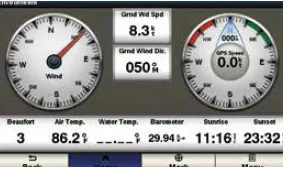

NMEA 2000 wind data collected by the sensor was simultaneously displayed via the NMEA 2000 system on both a B&G Triton display and a Garmin 741xs multifunction display.

Maretron WSO 100

Resembling a miniature spaceship, the round sensor is relatively compact-measuring 4 inches in diameter and just short of 3 inches tall, including the mount. Early versions of ultrasonic sensors were aimed at land-based meteorology, and we were initially concerned that these were too fragile for 24/7 service in a rigorous marine environment. However, the Maretron WSO 100, made of UV- and impact-resistant plastic, has the ruggedness of a thick-walled PVC plumbing fitting. It has a waterproof rating of IP67, meaning it can withstand submersion in water 3 feet deep for 30 minutes.

To gather wind-speed data, the sensor relies on acoustic windows. The acoustic windows for the three ultrasonic sensors are built into the pillars that support the upper and lower halves of the sensor. It weighs only 10 ounces, operates with 9-16 volts DC, and draws a modest 150 milliamps when operating.

Testers found that there are some nuances involved in mounting the WSO 100. The units separate, threaded base is first screwed onto the mounting pole. Then, the NMEA cable is passed up the pole, through the base, and connected to the WSO 100. Three stainless-steel, Phillips-head bolts are used to fasten the sensor to the mount base. The sensor must be oriented correctly; it has marks indicating which side should be facing forward.

With the NMEA cable attached, the unit should not be rotated more than about one turn; otherwise, the cable will twist. This means you will have to find some way to lock the threaded base in place once it is oriented. Maretrons installation instructions explicitly warn against using thread-locking compounds containing methacrylate ester, such as Loctite Red (271) as they will cause stress cracking of the plastic enclosure. However, they do not recommend any acceptable substitute for locking the threads.

We used a silicone sealant on the mount threads. It held securely and still made it possible to remove the sensor if needed. You should allow at least 3 inches of slack in the NMEA 2000 cable so that if you need to remove the sensor, you can lift it up and remove the cable connector without twisting it.

When planning to install a Maretron wind sensor on your masthead, you have to keep in mind the differences in footprint size from your previous unit. The antenna base that the Maretron uses is 4 inches in diameter, while the mount for the typical cup anemometer is a much smaller area, typically a rectangle covering about 3 square inches. Some masts may not have enough room for the Maretrons antenna-style mount, although with a bit of ingenuity, you should be able to make it fit. Online forums suggested a range of possible mounting options: custom-bent stainless-steel pipe; the Glomex V9173 stainless-steel television antenna mount; side mounts; extension plates at the top; and even mounting the Maretron sensor on top of a tricolor mast light.

For the most accurate readings, we recommend locating the device about a foot above all other devices mounted on the masthead and as far away as possible from mast-mounted VHF antennas.

Although our initial tests did not induce any interference, we have witnessed N2K communications temporarily disrupted by VHF transmissions. The effects, however, only occur during transmission, and do not appear to cause any damage to the sensor or the network. Although we have not tested for this, it could pose a problem, if you were interfacing your autopilot with the wind sensor.

During our previous wind sensor tests, we noted the tendency of anemometer cups to give slower or faster wind readings when they were turned at an angle to simulate a heeling sailboat. In fact, all of them suffered from this effect, except the propeller-style Garmin Gwind sensor. One of the advantages of the WSO 100 sensor is that it is virtually immune to this effect. It continued to record accurate wind speed and direction data at angles up to 45 degrees.

The WSO 100 was connected to both a Garmin 741 multi-function display and the B&G Triton display. The Garmin was used to provide a GPS fix to the NMEA 2K network. GPS data allows the WSO 100 to calculate true wind speed. For future testing, we hope to also interface the WSO 100 with one of the Maretron displays.

In Part III of our series on wind instruments (see PS August 2014 online), we noted that when trying to mix and match brands of wind sensors and displays, calibration became an issue. Most multifunction displays (MFDs) and some simple wind data displays can be calibrated to account for a wide range of variables, such as angle of heel, offset mounting, etc. Users can also configure the damping (how frequently the wind data is sampled).

If you are keeping your old display, but upgrading to a Maretron sensor, make sure that the display is compatible with the device, and find out what-if any-N2K sensor calibration options you might lose (or gain). Regardless, you will want to make sure you have upgraded to the most recent software.

Under the WSO 100s default factory settings for damping, the wind speed and direction data is recorded every 1.5 seconds. This is a good setting for the daysailor and typical cruiser. If the software for the N2K display youre using does not allow you to configure angle offset, you will have to manually adjust the sensor angle at the time of installation. Since the front of the sensor is clearly marked, noting the sensors orientation is fairly easy-as easy as anything can be when you are working 40 feet off the ground. Maretrons own display software allows users full control over a range of offsets-including angle, speed, and damping.

While spot-on wind speed and angle of wind-speed may not matter much for the cruising sailor, precise calibration is essential for the racer and high-performance cruiser, and it becomes more essential once you start integrating with an autopilot. For sailors with an existing Maretron N2K network, a far more substantial set of calibration features are available, including the ability to dial-in the most accurate humidity, barometric pressure, and air temperature readings. Advanced users can enable/disable PGNs (sets of data) and assign priority to certain data. For example, if you had two GPS devices, you can designate which GPS should be used when calculating true wind.

Conclusions

When ultrasonic sensors first gained a foothold in the sailboat market about 10 years ago, they struck us as expensive and fragile. Prices have dropped, and weve modified our view regarding durability. While we wouldnt go around dropping the Maretron WSO 100 the way we have some of our mechanical sensors, it is a solidly built piece of equipment that should not give any trouble when used as directed.

Installation and the owners manual are both straightforward. Its two-year warranty matches those offered by Raymarine, NKE, and B&G; and it beats Garmins one year of protection.

Prices have also leveled out. West Marine sells the WSO 100 for $600, but you can find it through online sources for about 10 percent less. That is about $150 more than the Gwind and the B&G 508, two of our favorite mid-priced mechanical wind sensors. It is about half the price of our Best Choice mechanical wind sensor from NKE, which offers the precision accuracy and responsiveness that racers demand.

While pro-am racers will still lean toward cup-and-vane sensors, for cruisers, the Maretron WSO 100 is very attractive. It provides all the key data and adds the ability to collect weather data like barometric pressure and humidity-and it is more birdproof than some of the other sensors we tested. Cons are that older boats will have to rewire with NMEA 2K, some non-Maretron displays don’t offer full control over calibration features, and the style of mount might be tricky for some masts, particularly for smaller boats (25 to 30 feet) with older masts.

We gave the WSO 100 a Recommended rating for boats already equipped with N2K systems. There was very little not to like about this technology-particularly for the technophile sailor-and as we move on to compare how well these wind sensors integrate with autopilot systems, we suspect it might climb a little higher in the rankings.

Interesting reading; we operate an early model of the LCJ-Capteur CV3F since 2006; this is a rugged built unit, not prone to attacks by seagulls etc and has a specification matching or better than regular anemometers. It is particularly accurate in low winds as it doesn’t need “to break free” and will not undergo wear and tear on the bearings which all mechanical units eventually will do. They now offer units for various performance requirements and pricing is in the same range as the anemometer units. It will tie into any system electronically. Certainly worth a look. https://lcjcapteurs.com/en/categorie-girouette-anemometres-capteur-vent/marine-en/

Just one more: we are particularly

pleased how even our 15 yr old CV3F unit performs with our cetrek 619 AP when this is set to wind steering; even with the now old wind unit sending data only at 1Hz into the name 0183 network of the vessel and a boat which is very lively on the rudder the AP sails perfectly well under wind setting. I am sure a more modern version with higher data frequency would even do better.

However the overall performance is much more depending on the possibilities the AP software offers to trim the system than it is depending on the wind unit. The Cetrek 619 was an excellent machine when it comes to adaptation on a particular vessel.

Thank you Lutz Von Meyerinck to talk about our ultrasonic wind sensor CV3F and to get your experience feedback. Actually it’s very interesting to get that kind of test, unfortunately we can’t find our ultrasonic wind sensor CV7. It’s quite unsual because Airmar is using our first patent to develop their range.

Hope to watch more tests like this. Good work !