The very first project tackled on my new-to-me catamaran a decade ago was to wrap the helm wheel with line. Our delivery trip home took place in late December on the Chesapeake Bay, and I didnt want to spend the next three days with an icy stainless steel wheel sucking all of the heat from my fingers. Instead, I spent a productive hour before dinner wrapping the wheel with line.

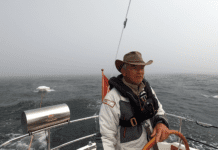

I also wrapped some railings surrounding the cockpit and on-deck; in these cases, its a safety issue. Cold, wet stainless is a nightmare and I’ve got old, tired hands. If you look around at Clipper Race boats you’ll find wrappings on pulpits and around the helm.

I’ve had leather-wrapped wheels and tillers. It’s expensive, and without regular treatment, soon becomes hard and cold.

I’ve held wheels wrapped with firm line in intricate coach whipping patterns. While lovely to behold, the knots were irritating and the treatment used to preserve the line (a lot of work goes into an attractive job) made the surface hard and unfriendly. I chose a much simpler approach, just a plain wrap with -inch nylon/polyester blend line. The wheel is warm in the winter, cool in the summer, has better grip, and increasing the diameter from -inch to 1 1/8-inch makes for a more ergonomic handful.

Begin by taping about two inches of line to the wheel in the direction you will be wrapping. This will be locked by the wrapping over it. Allow this tail to unlay, minimizing the lump. Athletic tape is best-it conforms well, is more non-slip than electrical or rigging tape, and will not creep over time in the heat as other tapes will.

Wrap loosely about five turns at a time, pausing to work the turns toward the start, snugging lightly. Continue, pausing every 5 turns, until the segment between spokes is full.

Using a rubber-faced glove, twist the line tight, turning and pushing in the direction of the start, so that the line is tight against itself. Repeat this several times, until the line is very tight.

On a wheel, start next to the king spoke and finish by going one turn past the spoke and then wrapping part way down the spoke.

Terminate by wrapping the last inch with rigging tape. This can also be finished with a turks head knot, if you like decoration.

We’ve also applied this same treatment to stainless railings, above and below decks. The wrapping increases the diameter to a safer handful; most boat railings are a spindly -inch or 1-inch polished stainless. OSHA, on the other hand, requires hand rails be 1 -inch. The average baseball bat, hockey stick or hammer is about 1 -inch, often fattened with tape beyond that. Why would we accept anything less secure on a wet and wildly pitching deck?

The only down side is that tether clips, even larger alloy models like the Kong Tango and Wichard Proline, cannot clip the line-fattened rail; if the hand rail or pulpit is strong enough to serve as a safety anchor and will be used in that way, leave a few inches clear near the base, where it is the strongest.

A line wrapping lasts about 10-15 years under the dodger, or about 8 years in the open. It will become stained with whatever is on your hands; an occasional soak and scrub with laundry detergent helps. Colored line is also an option. But to me comfort and safety rank far above gleaming white. Eventually, its a minor project to refresh.

Drew Frye is a technical editor for Practical Sailor. He also blogs at his website.

Drew,

I could not see in the article what size line you are using? How much line did you use for your various wrapping projects? In other words, about how much line per linear foot of wheel?