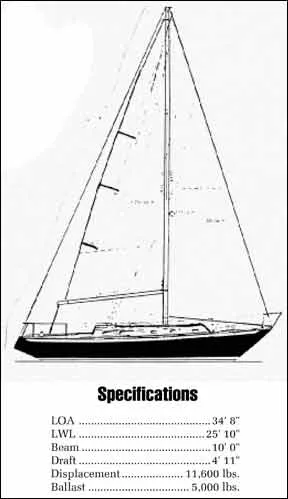

Ericson Yachts has gotten a lot of mileage out of 35-footers over the years. Way back when in 1965, the first Ericson 35 was a typical CCA cruising boat, with a long keel and attached rudder. In 1969, the Ericson 35-2 was introduced. A Bruce King design—as was the original 35—the 35-2 was an up-to-date racer/cruiser, with swept-back moderate fin keel, pronounced bustle, and semi-balanced shallow spade rudder.

The 35-2 stayed in production until 1982, when it was replaced by the 35-3, a larger, more modern boat. The 35-2 was a very successful design—about 600 were built over 13 years. She was not an IOR (International Offshore Rule) design, but the boat rated reasonably well under the new rule, and raced competitively at the local level.

Early IOR boats were little different from their late-CCA predecessors. It took designers several years to develop the types of ill-tempered boats that we now think of as IOR designs. This allowed wholesome production boats such as the Ericson 35 to be reasonably competitive at the local level.

The 35-2 is a good-looking boat. She has a very strong sheerline, powerful forward but not overly springy aft. The stern is hollow in profile, and the stem profile is just convex enough to look like a straight line.

The deckhouse is low in profile, despite the relatively low freeboard of the boat. Aesthetically, the only thing you can quibble with is the overly wide transom, which is fortunately not very high. A lot of current boats, of course, have transoms as wide as the Ericson 35’s, and they practically drag the bottom of the transom in the water. The temptation to use these ugly modern rear ends as billboards has proven overwhelming, resulting in a whole new industry in the last decade: transom art. In comparison to many of today’s production boats, the 35-2’s transom looks positively dainty.

Sailing Performance

With a typical PHRF rating of 150 to 156, the Ericson 35-2’s performance is respectable, but the boat is no hot rod. She’s about the same speed as a Ranger 33.

You need to put the concept of speed into perspective. Despite a lot of “harumpfing” about the poor sailing qualities of modern boats, the fact is that the average fin-keel production cruiser/racer built today is faster—a lot faster—than good boats designed 20 years ago, such as the Ericson 35-2. Appendages and rigs are more efficient, wider beam gives greater sail-carrying ability in a breeze, and hull shapes are frequently more refined, as long as they’re not overly influenced by the rating rules.

The newer Ericson 35-3, a slightly larger boat—she’s closer to 36′ than 35’—is about 30 seconds per mile faster than the 35-2. Same designer and builder, same concept; faster, more modern boat.

At the same time, an older production racer/cruiser such as the Ericson 35-2 is likely to be a lot faster than today’s straight “cruising” boat. The Crealock 37, for example, is about 20 seconds per mile slower than the Ericson 35-2. “Fast” and “slow” are pretty relative concepts, particularly when you’re moving at a slow jogging pace.

Despite a 43% ballast/displacement ratio, the 35-2 is not a particularly stiff boat. Owners give the boat average marks for stability, frequently commenting that stability is not a problem as long as sail is reduced appropriately. Frankly, this is true on almost any reasonably high-performance boat. We’d shy away from any boat that claims to be able to carry full sail upwind in 20 knots of breeze: the boat is likely to be grossly underpowered in light air.

The “average” stability stems from relatively narrow beam and relatively shoal draft, and is certainly not a major concern. We would recommend that you make a real effort to stow heavy equipment as low in the boat as possible—the boat’s vertical center of gravity is somewhere around the height of the tops of the settees. You should also set up the boat so that she can be reefed as easily as possible.

You’ll find both tiller and wheel steering on the 35-2. The cockpit is divided into two sections by a full-depth fiberglass bridgedeck which carries the mainsheet traveler. On wheel-steered models, the helmsman steers from the aft cockpit, and the sail handlers work from the forward cockpit. In tillersteered boats, the helmsman sits toward the forward end of the main cockpit.

For best weight distribution, the forward helmsman’s position is better, but it’s tough to keep sheet tenders and the helmsman out of each other’s way if they’re both in that forward cockpit. When racing tiller-steered boats, the mainsheet tender will sit in the aft cockpit.

The aft-mounted wheel does clean up the forward cockpit nicely, giving you very good lounging space.

Several owners have added 400 pounds or so of additional ballast, and report that it makes the boat slightly stiffer without noticeably slowing her down in light air. There is plenty of room in the keel shell to add some extra ballast if you want, but we’d live with the boat for awhile before increasing the ballasting. At the same time, we certainly wouldn’t remove ballast that had been added, as long as the boat trims to her lines fore and aft.

As designed, the main boom is very high off the deck, and has a pronounced droop at its after end. This is purely a device to reduce rated sail area for racing. Most boats never had droopy-clewed mains built, and we wouldn’t recommend one. Unfortunately, the high boom can make it really awkward for a very short crew member to furl the sail or hook up the main halyard.

Some 35-2s we have seen have no main boom topping lift. Instead, a short length of wire is seized to the backstay, and hooked into the end of the main boom. This is totally unseamanlike, and potentially very dangerous. This system should be removed immediately from any boat, and replaced either with a permanently-attached topping lift, or a fixed vang such as the Hall Quik Vang.

The double spreader rig—unusual on a boat this small when the 35-2 was introduced—allows for fair tight sheeting angles, particularly when you add in the narrow beam of the boat. The spar section itself is quite rugged—not something you can bend very easily. You wouldn’t want to bend the rig much in any case, since the mast is deck-stepped.

This is a good all-around sailing boat, with no particular quirks either upwind or downwind. The boat is not as fast on any point of sail as a newer, more racing-oriented design, but she’s a good, solid sailer.

Several owners mention substantial weather helm when reaching in heavy air, but there are few boats that don’t suffer from this. Ease the traveler down, flatten the main, and the helm should be reduced.

Construction

The Ericson 35-2 has an uncored hull built in a split mold. The two halves of the hull are glassed together with 11 laminations of mat and roving. There’s nothing wrong with building a hull in two halves as long as the joint is adequately reinforced, and this is the proper way to do it. Nevertheless, you should carefully examine the hull centerline on the outside of any boat you are considering, checking for cracks.

Several owners in our survey report that leaking shroud chainplates have caused significant rot in the main bulkhead. Keeping chainplates watertight is a constant battle, particularly on a boat that is sailed hard. Problems should show up in the form of discoloration or delamination of the main bulkhead where the chainplates pierce the deck.

Because this is one of those problems that can cause hidden damage, we would think twice about buying a boat that showed a significant amount of chainplate leakage. Unfortunately, the damage may be hidden under covering fascia at the edge of the bulkhead in the main cabin, so some disassembly and probing may be required.

The chainplates are stainless steel straps, with integral welded caps designed to be bedded to the deck. If the bolts holding the chainplates to the bulkheads are snugged up tight, and if the caps are thoroughly bedded in either polyurethane or polysulfide, you should be able to keep the chainplates dry. However, it may require a one-time disassembly and removal of the chainplates to properly bed and install them. Running a bead of compound around the edge of the chainplate caps won’t do the job.

The ballast is a lead casting dropped into the molded fiberglass keel. Examine the leading edge and bottom of the keel carefully for signs of hard grounding which may have damaged the keel shell.

Early 35-2s are equipped with gate valves on through hull fittings, rather than seacocks. Gate valves should immediately be replaced with more conventional tapered plug seacocks or ball valve seacocks, which can be firmly attached to the hull. Depending on the strength of the stem of the through hull fitting to support the shutoff valve—as you do with gate valves—is a risky proposition. We’ve seen plenty of through hull stems break off when you’re trying to open a stuck valve. You can end up with the valve in your hand and a big hole in the hull, which is a bit of a problem if your boat happens to be in the water at the time.

Headsail sheet winches are mounted on fiberglass islands that are part of the deck molding. One owner reports that the plywood reinforcement in the top of the winch islands has rotted, the result of an improperly bedded winch. Plywood is frequently used by builders to add compression strength to laminates under hardware. No builder we know of takes the time to seal the core that is exposed when you drill for through-fastenings, so bedding is required.

Ericson 35-2 owners report an average incidence of hull blistering: about 30% have at least some hull blisters. Owners of two boats in our survey said their hulls were badly blistered.

Engine

Up until 1973, you could get any engine you wanted in the Ericson 35-2 as long as it was the Atomic 4 gasoline engine. After that a variety of diesels were offered as options until 1978, when a switch to diesels was made throughout the sailboat industry.

The most common diesel used in the boat in the mid-70s was the Westerbeke 4-91, a heavy 25-horse engine. But you’ll also see Volvo, Yanmar, and Universal diesels, as well as the Westerbeke Pilot 20.

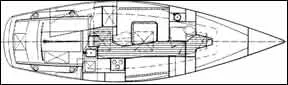

There are two different engine placements. In early models, the Atomic 4 is tucked under the aft end of the dinette, in the main cabin. Owners give this installation high marks for engine accessibility, and it keeps the weight in the middle of the boat.

Boats with the two-settee main cabin have the engine mounted aft, under the companionway. The engine is far less accessible in this location.

Watch out for terneplate steel fuel tanks on older boats. These are a potential fire hazard, as they are very susceptible to rust-out. The fuel capacity of 22.5 gallons is adequate for any of the standard engines.

Several owners report having incorrectly-propped engines, although it is not clear whether these are original engines or replacements. With either the Atomic 4 or any of the optional diesels, the boat should do at least 5 1/2 knots under power in calm seas at normal cruising revs. Don’t count on using the stock 12 x 6 prop with anything but the Atomic 4. Likewise, the standard 3/4″ shaft is a little small in diameter for any engine bigger than the Atomic 4.

The original engine exhaust is a water jacket system, fabricated of steel. Pinholes eventually develop between the walls of jacketed systems. These can allow water back into the engine. We’d recommend replacing water jacket systems with a simple, modern waterlift.

Interior

Despite the narrow beam, the Ericson 35-2 has a reasonably roomy, well thought out interior. Actually, it has two somewhat different interiors.

Interior decor changed significantly over the years. Early boats have mahogany interiors: varnished mahogany bulkheads, mahogany trim, mahogany hull ceiling. Very late boats have the all-teak interiors that became the fashion by the late 70s.

The all-teak interior is very dark, although rich-looking. The best thing to do with the teak interior is to varnish it. Use matte-finish varnish for veneered surfaces such as bulkheads, and high-gloss varnish on all solid wood. Of course, this is a lot of work.

The main reason that builders went to teak interiors is that they save a fortune in finishing time and money. The higher cost of teak is more than offset by the time savings. To properly varnish the interior of this boat would take about 200 hours, while a coat of oil could be applied in two working days.

The mahogany interior of older 35-2s is substantially lighter in color then the teak interior. There is also more contrast between the face veneer of the plywood bulkheads and the darker color of the solid mahogany trim. The mahogany must be kept wellvarnished; an oil finish will not provide adequate protection for the mahogany surface.

If you’re tired of dark wood interiors, it would be fairly easy to paint out the varnished mahogany ply interior. Simply sand the surface to remove all trace of gloss, then paint with a low-luster finish such as Interlux #221 Cabin Enamel. Leave the solid wood trim varnished for a nice contrast.

Painting out teak veneer surfaces is more of a problem, since the teak is likely to be oiled. Paint adheres poorly to teak in the best conditions, and very poorly to oiled teak.

All models have a conventional forward cabin: Vberths, storage shelves over, drawers and bins below. The 25-gallon stainless steel water tank is also mounted under the berth. This is an inadequate water supply for a boat with five berths that is to be used for anything more than weekend cruising. Several owners report adding additional tanks. Don’t add them up forward, as it would change the trim of the boat.

Thanks to fine forward sections, the foot of the Vberth is extremely narrow. Several owners have built inserts to turn these berths into a double, but the job is complicated by a cutout at the head of the starboard berth, a feature designed to add elbow room.

In port in good weather, ventilation in the forward cabin is good, thanks to an opening overhead hatch. In rain, it’s not so good: no cowl vents.

Older boats have padded vinyl hull liners forward; newer boats have teak ceiling strips.

The head compartment is reasonably roomy, and has good storage. There’s a cabinet under the sink, and a locker outboard. There’s also a large, tall locker next to the toilet, to which the forward lower shroud chainplate is bolted. Check for signs of leaking around this chainplate.

Ventilation in the head leaves a lot to be desired, but could be improved by a larger cowl vent and a small overhead hatch.

A shower sump was standard, but not all boats were equipped with pressure water. If you install a shower, don’t forget to provide a sump pump. You don’t want your shower to drain directly into the bilge.

Both main cabin layouts are roomy and comfortable. Bruce King and Ericson wisely decided not to try to get a pilot berth into a relatively narrow boat, opting for more elbow room and a little storage outboard of the settees.

A settee stretches along the starboard side of the main cabin. The settee is pushed fairly far forward to get more room in the aft galley. A cutout in the starboard forward bulkhead provides a footwell, making the settee long enough to use as a berth.

There is a narrow shelf behind the settee—a good place to store books.

In the two-settee layout, there’s a drop-leaf table just off centerline, allowing comfortable dinner seating for four on the two settees.

The dinette layout has both plusses and minuses.

The fixed table can be lowered to form a big double berth, but in our experience, this type of arrangement is a nuisance. You need a big cushion to fit over the table, and that cushion has to be stowed somewhere when it’s not in use. The multiple cushions required to create the dinette double never seem to fit together quite right, resulting in a berth that is big enough, but rarely comfortable.

In addition, the offset dinette table is too far away to allow use of the starboard settee for dining, so the dinette is it as far as company for dinner goes. It seats four in reasonable comfort, but as in most dinettes, you end up playing footsie with your dinner partners a lot of the time, which may or may not be a bad idea.

In the dinette layout, the engine is shoe-horned under the aft seat. This was fine with the Atomic 4, but it’s hard to fit a diesel in the same space.

It’s also pretty hard to effectively sound isolate an engine mounted in the middle of the main cabin, but modern insulation materials can help a lot.

Ericson owners are divided on the merits of the two main cabin arrangements. The midships engine is easier to service, but you sacrfice a lot of walkingaround room in the main cabin. Look at both layouts before making a decision.

The aft half of the main cabin is virtually identical in both interiors. To port, there is a good-sized chart table, with enough space outboard to mount a reasonable array of goodies. The huge quarterberth forms the seat for the nav station.

To starboard is an L-shaped galley. Considering the vintage of the boat, the galley is quite good. There’s room for a three-burner gimbaled stove with oven (though you’ll find only alcohol stoves unless someone’s done a retrofit). Aft of the stove is a decent working surface, with big drawers below. A single deep sink is mounted in the counter just below the companionway, with a big locker beneath.

The icebox is tucked back into a corner, but it’s reasonably accessible, if a little small for extended cruising.

Both the battery selector switch and the electrical panel are mounted on the bulkhead aft of the galley. That puts them close to the battery, but the nav station would be a more logical location for electrical system management.

Main cabin ventilation is provided by a big overhead hatch, but there’s no provision for ventilation in bad weather.

Surprisingly, the cabin sole throughout the boat is the molded fiberglass floor pan, with teak ply inserts. Compared to the finish in the rest of the boat, this is an unattractive detail, smacking of cost-cutting. Finish in general is of good production boat quality.

Detailing is only average.

The interior of the 35-2 is not in any way innovative, but it is roomy, decently finished, and well thought out. There has been no attempt to cram in a superfluous number of berths—if you ignore the dinette double—and there is reasonable privacy for a family.

Conclusions

The Ericson 35-2 is a wholesome family cruising boat. She sails well, and has enough exterior teak trim to look nice if you want to go to the trouble to keep it up. The Ericson molded fiberglass toerail is not particularly attractive, but it’s a lot less maintenance than a teak toerail.

These were not lavishly-equipped boats. A lot of things that we take for granted today—multiple batteries, hot and cold water, a shower, self-tailing winches, double lifelines—were either optional or not available, particularly on early models. Some production shortcuts on older boats—steel fuel tanks, gate valves, small water tank—should be corrected at once, if they haven’t already been replaced.

Since a lot of these boats have been raced, you may find a 35-2 with up-to-date sailhandling equipment, bigger winches, and good sails. Because of big differences in age, engine, equipment, and condition, prices range from bargain-basement to close to newboat prices for entry-level boats of the same size.

This would be a good boat to move up to for a family with two children and a tight budget. The boat sails well enough to do a little club racing if you’re so inclined, and it’s the type of boat that serves as a reasonable teaching platform for older kids interesting in racing bigger boats. Unlike many modern cruisers, she’s not a clunky sailing houseboat.

The relatively shoal draft will allow you to get into places inaccesssible to boats with a deep fin keel, making the boat suitable for areas such as Florida, the Chesapeake, and the Gulf of Mexico. With a little thoughtful upgrading and after a careful survey, you could do some limited offshore sailing—trips like Florida to the Bahamas—while you develop confidence in the boat, and in yourself.

Great article!

As you mention “well thought out” I find my favorite thing about my 1972 E35-2.

Many boats will have a U-shaped kitchen area or a dedicated nav station, and though these might look good in photos they wind up taking a tremendous amount of space that doesn’t get used a lot.

The kitchen only takes up a few feet while providing a great deal of space to cook, and the seat for the nav station is the rear quarter berth.

We turned our dinette into a large lounging area and truly enjoy how roomy the interior is visually. The cut out shelf in the starboard bulkhead gives visual depth appearance to the interior almost creating the illusion that the walls are very thick. As you mentioned in your article the water damage should be assessed for all chain plate areas because the wood that is used in the bulkhead is not marine grade but instead hardwood interior ply. If any delamination is present they must be replaced. Since most of the vertical tension from the chain plates is within the 1st 1.5ft from the hull towards the centerline, we were able to replace the bulkhead for the first 18 inches leaving the rest of the bulkhead intact using a dovetail joint and fiberglassing both sides.

With new marine grade plywood and fiberglass on both sides and penetrating Epoxy in the plywood, our 50 year old boat is ready to make a run for Hawaii with new Bomar and Lewmar hatches, along with other refits.

Oh and she sails hands free at 20 degree to weather under full sail without need for an auto pilot, or locked helm. Bruce designed a boat that adores the sea in all conditions.

Comments are closed.