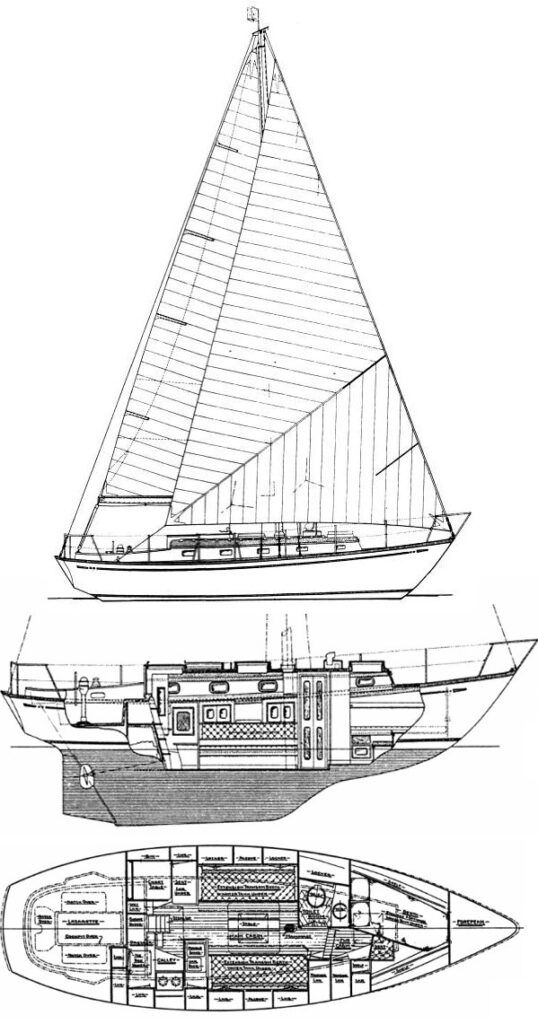

The Mason 33 was built in the mid- to late ’80s by the Ta Shing yard in Taiwan, and imported by Pacific Asian Enterprises in California. She is a moderate traditional design that harkens back to the CCA handicapping rule of the 1960s. It might best be described as a modern full-keel hull, with a cut away forefoot and sharply turned bilges to reduce wetted surface. Though narrow and short on the waterline compared to modern lightweight fin-keelers, she is beamier, with shorter overhangs, than you would find on a typical 1960s design. If the CCA racing rule had survived into the 1980s, we suspect the Mason 33 would be a typical, if conservative, specimen.

PAE’s requirements to the designer were for a seakindly hull with the capability for carrying ample stores and an ability to take a couple or small crew anywhere. The company makes no bones about their distaste for the standard issue contemporary finkeelers, which they dismiss as limited-purpose boats, suitable only for minimal coastal cruising, with too many berths and totally inadequate storage space. They believe the moderate traditional design of their 33 makes for not only comfortable coastal cruising and daysailing, but also blue-water passagemaking and as a living aboard. And it’s conceivable you could even race one in PHRF.

CONSTRUCTION

The hull is a standard solid fiberglass hand-laid laminate. It’s different from others in a couple of respects. The company specified a somewhat heavier than normal laminate, and the hull also has four full-length longitudinal stringers to give additional support to the bulkheads and floors.

Isophthalic resin is used in the laminate—the current theory is that iso resins are less water permeable and hence less likely to allow hull blistering to develop. PAE also recommended that buyers have an epoxy coating put on at the factory.

The ballast keel is iron, placed inside the hull molding in two pieces, taped into place, and sealed to minimize rust or leakage problems in case of a hard grounding. Americans are more accustomed to lead keels, which are unquestionably preferable for exterior ballast, but iron interior keels are fairly common in the Oriental boats, and we don’t hear of many problems. (The external iron keels common on European boats are more rust prone and a higher maintenance item.)

| Mason 33 | Courtesy Sailboatdata.com |

|---|---|

| Hull Type: | Long Keel |

| Rigging Type: | Masthead Sloop |

| LOA: | 33.75 ft / 10.29 m |

| LWL: | 25.42 ft / 7.75 m |

| S.A. (reported): | 602.00 ft² / 55.93 m² |

| Beam: | 10.83 ft / 3.30 m |

| Displacement: | 14,269.00 lb / 6,472 kg |

| Ballast: | 5,320.00 lb / 2,413 kg |

| Max Draft: | 5.00 ft / 1.52 m |

| Construction: | FG |

| First Built: | 1984 |

| Last Built: | 1989 |

| # Built: | 20 |

| Builder: | Ta Shing Yacht Building (TAIWAN) |

| Designer: | Al Mason |

| Make: | Westerbeke |

| Model: | 35C |

| Type: | Diesel |

| HP: | 35 |

| S.A. / Displ.: | 16.43 |

| Bal. / Displ.: | 37.28 |

| Disp: / Len: | 387.81 |

| Comfort Ratio: | 33.08 |

| Capsize Screening Formula: | 1.79 |

| S#: | 1.17 |

| Hull Speed: | 6.76 kn |

| Pounds/Inch Immersion: | 983.67 pounds/inch |

| I: | 44.80 ft / 13.66 m |

| J: | 14.60 ft / 4.45 m |

| P: | 38.30 ft / 11.67 m |

| E: | 14.75 ft / 4.50 m |

| S.A. Fore: | 327.04 ft² / 30.38 m² |

| S.A. Main: | 282.46 ft² / 26.24 m² |

| S.A. Total (100% Fore + Main Triangles): | 609.50 ft² / 56.62 m² |

| S.A./Displ. (calc.): | 16.64 |

| Est. Forestay Length: | 47.12 ft / 14.36 m |

| Designers: | Alvin Mason |

| Builders: | Ta Shing Yacht Building Ltd. |

The deck molding is a standard glass layup with balsa core, with plywood in the cabin trunk and other spots to provide additional backing strength and attachment points for the interior joinerwork. The non-skid on deck is satisfactory, but the optional teak overlay is generally preferable. While it did cost $2,280, the price was reasonable (probably about a third of what it would cost in the US), especially considering the quality of it and the finished appearance it gives the boat.

Further, the hull has the displacement, ballast, and form stability so that the added weight of the teak deck won’t be the problem it could be on a lighter design.

The hull-to-deck joint is a standard inward turning hull flange, on top of which the deck rests. It’s somewhat unusual in that the teak toerail sits on top of (and hides) a stainless steel flat bar on top of the deck. Inside the hull there’s a matching stainless flat bar. The flat bars act as extended washers for the through bolts which fasten the joint together, with every other bolt going through the toerail as well as through the joint. About the only complaint we have heard about the older Masons was some leaking in the hull-to-deck joint, but it’s hard to see how the joint could leak on the 33.

The exterior finish of the hull and deck is generally good, with no evident hardspots to mar the fairness of the hull in any of the three boats we examined. The gelcoat work also appeared good. Although we went over the topsides and cabin house of one of the three boats carefully, we found no flaws—a rarity in fiberglass boatbuilding.

The boat has fairly extensive teak trim on the exterior, most notably the heavy-duty toerail, cockpit grates, and cabin trim. The standard hatches are teak, with lexan tops. If you’re not into the high maintenance of wood hatches, you could get optional Goiot or Taiwan brand (“Manship”) hatches. (The Taiwan hatches look like knock-offs, as well made but cheaper than the Goiot.) Having the exterior teak varnished was a $625 option. The result is the look of real quality, but requires the owner to get involved with the continuous maintenance required of varnished teak.

One of the things that marks the construction as good quality is the exterior detail. The custom made cleats and chocks, for example, are well done and well fitted to the teak trim, and the little stainless steel chafing strips to protect the teak around the stern chocks are just one of the many nice touches.

Although we might have preferred some things to be different (like using lead ballast rather than iron), it is clear that the developers and builder have given thought to all details of the boat’s construction. Overall, it is hard to find fault with any aspect of it.

HANDLING UNDER POWER

Early models of the boat came with a 21-hp. Westerbeke, normal for an offshore cruiser but probably near the minimum size for the American market. Later boats have a Yanmar three-cylinder diesel, at 27 hp adequate for the boat and more in line with what most Americans like in a coastal cruiser. The fuel tanks holds 35 gallons for a good powering range.

Standard is a three-blade propeller. A two-blade would be much preferable for performance under sail, since it could be positioned upright in the aperature between the aft end of the keel and the forward edge of the rudder. However, under power, the two-blade “hammers”—that is, it creates a sharp vibration because the two blades are alternately in the water flow but then hidden behind the keel and not pushing any water when vertical.

The hammering is a minor irritant, but we can imagine it becoming major during long motoring sessions. Unfortunately, it is inherent in the hull design.

The company recommended buying both a three-blade and a two-blade, using the three-blade most of the time but putting on the two-blade prior to long passages under sail. We would be inclined to go with a two-blade and put up with the vibration, but that’s a choice each person will have to make.

The boat we sailed had a two-blade prop and the Westerbeke diesel, and we found that the boat generally behaved well under power, being just a mite disinclined to back up in a straight line. Otherwise, she tracks and turns well, though long keel/attached rudder boats always have a longer turning radius than the fin keel/separate rudder models most people are accustomed to these days.

The engine installation is well done—there’s a good drip pan under the engine and everthing is neat and tidy. Full access to the engine, however, requires not only removing the companionway steps but also taking out a drawer assembly. It’s not a complicated job—you have only to remove two wing nuts, but it takes some time.

HANDLING UNDER SAIL

The Mason 33 is heavy by comparison to most boats its size, and it definitely has a different “feel” to it. We sailed it on a fairly calm day on the Pacific, but it was easy to sense that it would handle rough conditions in a more sedate fashion than typical modern lightweights.

Given that it is a long keeled boat with lots of wetted surface, it probably will not be a sprightly performer in light airs, but it has a powerful enough sail plan that the boat moved well in the 8-10 knots of air that we sailed in. Our sense was that the hull must be quite efficient for its type, since the boat sailed better than we expected in the conditions. Though we did not try it in heavy air, we suspect that the boat will be at its best sailing in a good blow.

The Mason 33 points well enough considering her outboard shrouds and her hull design, but windward work will not be her forte. She will do her best with the wind slightly ahead of the beam and next best from a beam reach to a broad reach. She rolls a lot dead downwind in heavy air.

Compared to modern racer/cruisers like the Pearson 33 or Beneteau 345, she will be quite slow for typical coastal cruising, especially in light air and to windward, but for sailing she was obviously designed for long distance passages, at which she should be respectable.

The boat comes with a mainsail and 100% working jib as standard equipment, so most people will want to add a genoa and spinnaker. The boat we sailed had a roller furling jib of about 130% which would be right for moderate- to heavier-air locales. For light-wind areas, a 140% would probably be better. The boat should handle a reefable 150% if you decided not to get furling gear.

The standard sails are made by Sobstad Watts. The main on the boat we sailed was good, the jib average. If we had a sailmaker whom we knew and trusted, our inclination would be to try to negotiate a purchase so we could have the sails made by our own sailmaker. However the standard sails are good enough that we wouldn’t feel “stuck” if we got them. That’s not common when stock sails come with a boat these days.

ON DECK

The teak decks, high toerail, and grabrails on the cabin top make movement around the deck easy. The walkways are plenty wide, and even the outboard shrouds require only a small duck and dodge when going forward.

We liked the deep cockpit of the boat, with its high coaming and comfortable seats, but it is somewhat smaller (more suited for seagoing) than is common nowadays. It’s definitely a cruising cockpit, and a racing crew of four or five would rapidly get in each other’s way, but it works well for a couple. Tiller steering is standard, but most everyone opts for the wheel which does provide more room. The cockpit lockers are enormous. They’re actually too big in the new boat configuration, and most owners will want to subdivide them with partitions, canvas, or netting so things don’t get jumbled.

The Lewmar #40 self-tailers are adequate, with easy access, but 43s are optional for weaker or harder-driving owners. A set of secondary winches is available; however, there’s scarcely enough room on the coaming top—we’d probably try to get by without them, even when flying a staysail or spinnaker.

The standard mainsheet winch is a Lewmar 16—we’d spring for the self-tailing Lewmar 30, since the traveler is ahead of the companionway and the sheet is not only loaded up but also prone to plenty of friction as it leads forward to the mast before turning down to the deck and back underneath the dodger coaming. Sail controls are minimal—you have to go to the mast to adjust the Cunningham, outhaul, or vang, so you won’t be doing much tweaking of sail trim.

The foredeck is small, adequate for sail handling and anchor work, but with not much room for sunbathing or lounging. The bow anchor roller is set up for a CQR. The forepeak is called a chainlocker. We would consider stowing nylon anchor rode there, but chain would put way too much weight forward. One problem to solve is where to put the anchors and rodes necessary for serious cruising. In this, the 33 is typical of most boats her size.

One shortcoming on deck—again inherent in the design of the boat—is that there is no good way to permanently install a swim ladder. The conventional transom mount does not work well because of the traditional slope of the transom, and a permanent mount has not been devised for the port or starboard side gates. The company sells a handsome teak ladder as an option, but it has to be removed and stowed when you’re underway.

BELOWDECKS

The interior of the Mason 33 does not look spacious. That’s partly because it is quite teaky and fairly dark, but mostly because everything inside the boat is good sized, especially the storage spaces. In fact, there is considerably more storage on the Mason 33 than there is on many larger boats, like the O’Day 40. We particularly liked the roomy forepeak (which has all but disappeared on many current boats), the double hanging lockers, the small hanging locker next to the companionway for wet gear, and the adequate space for food stowage in the galley.

Layout below is fairly conventional, but the spacing and all the details have been attended to—we found few nits to pick and many details that were pleasantly surprising.

The galley has ample fiddled counters and good deep sinks and should work well under sail. At anchor, it’s awkward in that the floor rises to follow the hull contour. The icebox is big enough and apparently well insulated, hot and cold pressure water are standard, and there are two water tanks for a total of 65 gallons.

Opposite the galley is the navigation station, with an adequately sized chart table and a sort of “screen” bulkhead to protect charts and electronics from sea or rain water entering through the companionway. The electrical panel is beautiful.

Settees are port and starboard of a centerline table, and a pilot berth is available portside, though most owners will likely use the space for storage. The head has a shower which drains into the sump tank, good storage space, and a decent wash basin.

| Market Scan | Contact |

|---|---|

| 1985 Mason 33 | Eastern Yacht Sales |

| $69,900 | 781-417-5266 |

| Portsmouth RI | Yacht World |

| 1986 Mason 33 | Gunnar's Yacht & Ship |

| $99,500 | 414-240-1121 |

| Waukegan IL | Yacht World |

| 1985 Mason 33 | Brewer Yacht Sales |

| $52,500 | 860-399-6213 |

| Pocasset MA | Brewer's Yacht Sales |

The berthing arrangement makes it clear that the boat is primarily designed for a couple, with perhaps at most one child or two young children and only occasional guests.

Notable below is the joinerwork which is uniformly of good quality. Teak is most everywhere—either veneered plywood or solid—with white formica as contrast. Hatches and portholes provide good light, augmented by deck prisms. Ventilation is adequate, with a big dorade and cowl forward, exhausting the forward cabin and head, and ten opening ports as standard equipment. For passage-making, a couple more deck vents would be desirable.

CONCLUSIONS

We hate to sound mush headed, but there is simply little to criticize in the Mason 33.

It is true that some people may not like the full keel design of the boat, preferring a lighter, high performance hull. But given the design, there is hardly anything wrong.

Her construction is solid, her deck is well laid out with good equipment, her spars and sail handling equipment are good quality, her interior is well laid out and well finished, the machinery and mechanical systems are made well and installed properly, and she’s a pretty good looking boat, though on the plain side.

We can’t even object to the price. She is expensive, but there are almost no boats of comparable quality in her size range, and the few you could buy are so much more expensive that they are not realistic alternatives.

For someone wanting a serious blue water cruiser or a livaboard boat in her size range, she is the logical choice. For others, wanting a coastal cruiser or a weekender/daysailer, she is probably less practical—more boat than would be needed. But of course many people buy not just a boat, but the dream of being able to take off at any moment and leave the boss and the rat race behind. The Mason is one of the few boats we’ve seen recently that is capable of actualizing the dream.

This article was first publlished on June 14, 2000 and has been updated.