If sailboats were defined in human terms, the Melges 24 could easily be described as having the attributes of a precocious three-year-old who hadn’t learned to respect her elders. More than likely, she also would be described as being gifted, if a little high strung.

Introduced as a prototype at Key West Race Week barely three years ago, the Melges 24 has already created the same sensation in the small boat performance world as the J/24 when it was first introduced. We’re not suggesting that we should commence composing the epitaph for the J/boat, especially since hull number 5,500 was launched recently and sales are still strong, but we are preparing ourselves for a high noon, main street shoot-out between the aging sharpshooter and the young gun as they wrangle for ownership of the small-boat race market.

Let’s set the stage: In the mid-seventies, Ron Moore began building the George Olson-designed Moore 24, one of the first in the breed of ultra-light, ultra-fast boats produced in Santa Cruz. On the opposite coast, Rob Johnstone introduced the J/24 in Newport, Rhode Island, and another in a series of dramatic changes in the industry was underway.

In addition to having the handling characteristics of a dinghy, these new boats carried tall rigs and moderate sail plans, so were especially fast off the breeze. They were easy to rig at the dock, trailerable, well built, and the hulls were enclosed, so they had at least some interior accommodations and could not swamp. These attributes led to their quick acceptance in the sailing world by a new generation of sailors for whom performance is a religion, and by sailors who had tired of hanging overboard on a trapeze. When the dust settled, the J/24 had captured the marketplace, spawning a revolution that resulted in 60-boat fleets racing at major regattas all over the world.

The Boat and the Builder

Meanwhile, in the backwoods of Wisconsin, the Melges family continued a tradition of manufacturing boats for sailors in the heartland—people who sail scows through the water during the summer, then race iceboats on top of the water during the winter.

Harry Melges of Zenda opened the Melges Boat Works in 1945, carving a reputation as a major builder of scows, although he also constructed boats ranging in size from 12-foot marsh skiffs to moderately priced 30-foot cruisers. The company also builds sails for the boats it manufacturers. Son Harry, Jr., nicknamed Buddy, joined the operation during his teen years, and while honing his boatbuilding skills he also set about building a reputation as one of the finest sailors in the country. He eventually attained international prominence by winning a gold medal in sailing in the 1972 Olympics. Following an unsuccessful attempt to campaign his own boat in the 1987 America’s Cup, he joined Bill Koch as coskipper for the America3 effort in 1992, a fortuitous choice that played a major part in the development of the Melges 24. In his absence, sons Hans and Harry III assumed responsibility for operation of the company, and began hatching plans for a new performance boat.

“The twenty-four was actually Hans’ idea because he was convinced there was a market for a new boat in that size range,” Buddy admits. With input from Hans, the designers of Koch’s three America’s Cup boats, Jim Pugh and John Reichel, began the process of designing a pocket rocket that piggybacked many of the characteristics of that $64 million dollar project. “I’d throw in a suggestion here and there, but Hans deserves credit for its development,” Melges adds.

The first prototype for the 24 was completed in time for Key West Race week in January, 1993, when John Kostecki sailed it into the winner’s circle.

“That first regatta provided the opportunity to test the design, and we learned that the boat was fast enough,” Hans recalls. “We sailed in very windy conditions and heavy seas so we tested our construction methods as well. When we took the boat back to the factory and gave it a thorough examination, we only found a couple of areas that needed improvements, which we made before we started production.”

By the end of 1994, 250 boats had been delivered in the United States, and Melges had entered into a joint venture with British Aerospace for production of the boats in Europe. One-design fleets have spawned across the country, and the fleet overwhelmed Race Week in January, 1995, with 63 entries.

Design and Deck Layout

Three of the characteristics that attracted boaters to the J/24 incited the Melges revolution: They are fast upwind and really fast downwind, well constructed, and trailerable. Because the new boat benefits from 15 years of design and construction improvements, comparisons to the J/24 are almost unfair, but do provide a frame of reference. For example: The J/24 is 20 feet on the waterline, weighs 3,100 pounds, carries 950 pounds of ballast, and flies 263 square feet of sail under a jib, 476 under spinnaker. Under PHRF, the J/24 typically rates in the 170s.

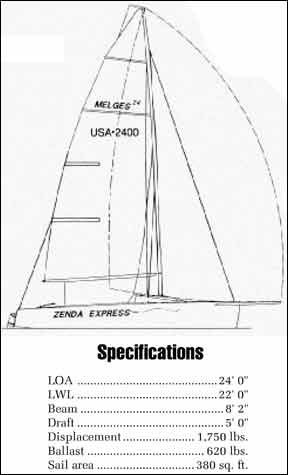

By comparison, the Melges is 22 feet on the waterline, displaces only 1,750 pounds, carries 620 pounds of ballast in a bulb keel, and flies 380 square feet of sail under the jib, and 920 under the spinnaker. Its displacement/length ratio is 73, the sail area/displacement ratio is 41.8, and it rates in the 90s under PHRF.

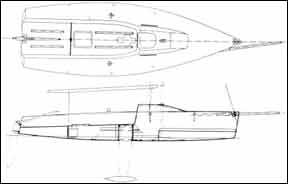

Aside from its plumb bow, narrow beam, flat bottom, hard bilges and open transom, one of the most striking features of the boat’s design is the enormous, 13-foot long cockpit, designed to allow crew to move quickly from side to side during tacks, and to position weight in pre-determined spots to maximize boat speed off the breeze.

The 6-lb. carbon fiber tiller extends into the cockpit to a point just aft of the mainsheet, which is housed on Harken track mounted on 3-inch risers on the cabin sole. When going to weather, the driver steers by using a 40-inch Ronstan tiller extension that allows positioning in front of the traveler while trimming the mainsheet and handling backstay tension. The mainsheet is led through a 3-inch Harken Hexaratchet and cam cleat.

Tacking requires some acrobatics, one of the few shortcomings on the boat, since the driver must step aft, around the mainsheet, which can result in a loss of control of the sheet, or step forward, which results in a temporary loss of tiller control.

Since the boat has no winches, a double-ended sheet is led from the jib through cars mounted on a track inboard of the shrouds, then aft to 3-inch Harken ratchet blocks that provide controls for upwind trimming. The boat is sailed with an asymmetrical spinnaker tacked to a bowsprit, so a similar arrangement is utilized for spinnaker sheets. However, since four crewmembers and all of the sheets seem to be concentrated in the center of the cockpit, we’d recommend the purchase of mesh sheet bags. The hull-deck joint and cockpit surfaces are smooth and well-radiused, so the crew is fairly comfortable when hiked out, especially compared to boats that require maneuvering around winch pods and seats on uncomfortable toerails when hiking. The absence of toerails, of course, creates certain risks. A single lifeline, stanchions and stern pulpit are included in the base price of the boat.

Melges has developed a clever way of dealing with storage of the outboard and the cooler. A lazarette in the cockpit sole accesses an 18-inch deep storage area that extends to each side of the hull and from the companionway aft to a bulkhead. A tray mounted on rails beneath the opening provides storage space for a 3-hp. outboard motor, which slides forward so it doesn’t clutter space below decks, and its weight is more strategically located. When it’s time for refreshments, a cooler mounted on rails

slides forward into the opening in the sole. The fuel tank also fits in the storage area.

Forward of the cockpit, things are fairly straightforward, although this is the first boat we’ve sailed that includes a bicycle pump as standard equipment. In lieu of a topping lift, a pneumatic, anodized aluminum Melges vang supports the boom and allows for height adjustment by varying air pressure. The outhaul exits the boom and is led through a block to a clam cleat mounted on the bottom of the boom so it can be tensioned from either side of the boat. The spinnaker halyard exits the aft edge of the mast into a cam cleat located just below the gooseneck.

One of the keys to the boat’s performance is a deck-stepped carbon fiber mast, manufactured in Minden, Nevada by Omohundro. Use of carbon provides plenty of strength, and reduces the weight of the spar and swept-back spreaders to only 62 pounds, a savings of approximately 25 percent, compared to aluminum. The roach of the main is large enough that the first boats produced were plagued by the sail hooking on the backstay when tacking in light airs so a mast crane now suspends the backstay clear of the sail. Similarly, concerns of excessive mast twist when sailing downwind were solved by the design of a fitting shaped like a “PacMan,” which attaches the crane to the mast and allows a modest amount of mast twist when under load. The mast is supported by 1 x 19 stainless steel uppers and lowers. Shrouds are tensioned by calibrated Ronstan turnbuckles. The tapered aluminum boom is fabricated in the Melges shop.

The headstay is a 3/16-inch wire that is inserted into the luff of the jib when preparing for sailing, so it doubles as the jib halyard. From the tack in a recessed Harken roller furler, the halyard runs the length of the jib luff to the masthead, from whence it is led internally to a turnbuckle located below decks. Once proper jib halyard tension is achieved, a Highfield-type lever mounted on the mast compression tube is closed to secure the arrangement.

The 6-foot long retractable carbon fiber bowsprit is mounted to starboard in the bow, where it is enclosed in a specially designed self-lubricating, neoprene seal designed to prevent water from intruding into the boat. Below deck, the bowsprit slides through supports in gussets mounted in the hull. The sprit is extended and retracted by pulling a line running from the tack below decks to the cockpit, where it is cleated on blocks attached to the inside wall of the coachroof.

Interior

As you would expect in a special-purpose boat, accommodations are spartan at best, and there’s little headroom. The mast compression post is located in the center of the cabin, the bowsprit extends aft almost to the bulkhead, and the spinnaker bag is attached to port, so there’s little room for movement. Though the forepeak is 6′ 5″ long, and quarterberths are long enough for a small person, prospects of camping on the boat aren’t particularly appealing. There’s adequate space for a portable toilet, and storage areas are located amidships and in aft quarters. Since the boat has no internal flotation, these bins could be filled with flotation material for those desiring a higher level of security. Some owners have added running lights and a KVH Sailcomp package, which necessitates the purchase of an electrical panel located on the coachhouse, and gel-cell battery housed in a storage area near the mast.

Construction

The hull and deck are cored with Klegecell foam; the skins are S-glass and biaxial fiberglass pre-impregnated with vinylester resin. A vacuum-bagging process assures a better laminate with fewer voids and more favorable glass-to-resin ratios. The hull and deck are handlaid in molds that Hans says result in one-mil tolerances. Bonding of the two structures is accomplished by application of a proprietary two-part adhesive system. There are no mechanical fasteners. (We have previously reported that TPI has been doing essentially the same thing in its Lagoon catamarans.)

The tiller and rudder are carbon fiber, the latter hung from the stern on stainless pintles and gudgeons manufactured by Melges. The keel is also carbon fiber, made by Omohundro. The bulb is lead. Both are nicely faired. Raising and lowering the keel is accomplished by attaching a wire attached to a gantry that fits into the cockpit to a stainless eye that screws into the top of the keel. Vertical Delrin guides are located on the side of the keel and fit snugly into similar bracing in the keel trunk. This assures that there is no keel movement when underway. Once lowered, the keel is secured by Kevlar straps buckled to the hull and covered by a fiberglass cover screwed flush to the cockpit sole. A unique feature of the design is a kelp cutter built into the front of the keel, a stainless blade attached to a rod that is operated by lifting a small knob in the cockpit sole.

Overall, the finished product reflects the manufacturer’s skill and attention to detail. For example, HI-200 and G-10 (high-tech, workable plastics) are used for backing plates and core replacement in areas requiring reinforcement.

Performance

The boat proved easy to launch. With assistance from Tim Carlander of VMG Marine in Seattle, we had the mast up, the boat rigged and were headed for the launch ramp 30 minutes after arriving. Hoisting the mast is accomplished by placing horns located on the foot of the mast into a bracket on the deck, attaching the spinnaker halyard to the trailer winch, and ratcheting the halyard as a crewmember elevates the spar by walking the length of the cockpit. We had the main up and the jib unfurled minutes after sailing away from the dock, and reached hull speed sailing on a beat in flat waters across Lake Union. Though sensitive to movement afloat, the boat felt solid. We learned quickly that driving takes practice; because the boat is so responsive we over-steered our first tack and finished with an accidental jibe. Similarly, we learned that tap-dancing around the mainsheet takes practice. Though the boat is sensitive to the crew’s movements, it tracks well, a function of the deep 5-foot draft and the keel bulb.

Because the asymmetrical, masthead chute was tacked to the pole before we left the dock, the set was a simple matter of hoisting the halyard and watching the sail exit a mesh bag attached with hook-and-loop strips to the companionway. We experimented by sailing on different angles and determined that the boat is fastest and most responsive when sailing high jibe angles, although we also sailed wing on wing significantly faster than a conventional boat with a drifter. Though we sailed quickly in a moderate breeze, it’s easy to imagine the 20-knot speeds recorded by racers in 15-20 knot winds.

Jibing takes some practice. Because the boat is not sailed with a spinnaker pole, the sheet must be eased quickly when the jibe begins, and the new sheet trimmed quickly, or the boat decelerates and the spinnaker wraps around the headstay. After three practice jibes we had the routine down, but would want more practice in heavier winds. Dousing is accomplished by gathering the sail as the halyard is eased, then releasing the tack and securing the sail in the bag. Re-hoisting can be accomplished in seconds.

Since our sail, Melges has developed a spinnaker bag with a fiberglass frame and canvas lid that fits over the companionway, an improvement that avoids the necessity of closing the hatch cover in heavy seas.

Sailing in non-racing conditions, we had the luxury of sorting things out slowly as we advanced up the learning curve. However, it’s apparent that layout and operation of the boat have benefited greatly from Reichel-Pugh’s input. New skippers and crews should be sailing the boat to speeds close to its polars as quickly as they devote the time to sort things out.

Conclusion

In our opinion, the basis of any evaluation of the Melges 24 starts with the understanding that this boat is about performance and shouldn’t be compared to boats having nicer accommodations and amenities. It’s going to provide thrilling, high-speed sailing, more than a J/24, for instance, and is probably best suited to experienced sailors. Early indications are that winning in this class will also reflect a high degree of sailing skill among the crew. When sailed in PHRF fleets in flat waters and moderate winds, the boats have proven their ability to collect trophies while defeating larger boats with similar or lower ratings.

With a 50-year history of building boats, and rapid responses to changes they felt necessary in the 24, the Melges family seems to have made a commitment to quality. Their design and construction techniques appear to be top notch and customer service is responsive. It’s hard to imagine being shortchanged from that standpoint.

With a base price of $34,500 for the boat, an additional $3,200 for a trailer, plus sails ($3,500-4,500), motor and other optional equipment, it’s easy to visualize a total expenditure of $48,000 or more. This price compares to a recently advertised “special” price of $29,400 for a new J/24 and trailer, or $29,900 for the Tripp 26 (see February, 1995) which rates approximately 110-115 under PHRF. Clearly there’s a premium to pay for all the carbon fiber, but that is the technology of today, and if you want to be at the leading edge, you need it.

Sailors take two points of view when evaluating the price of the boat, which is in the upper levels of the sport boat marketplace: One dismisses the boat as being too pricey, period. Others divide the cost by the rating and determine that, compared to bigger boats with a similar handicap, this may be a bargain, since it is trailerable, sailed with fewer people, has rigid class rules, is less complicated, and won’t be as expensive to repair when things break.