In 40 years of sailing I’ve lost only two winch handles. I was reefing the main when I lost the first. I reached up to close the jammer, was tailing with my other hand, and off went the handle. The second was left on the deck near the cockpit by a guest and slid off moments later. Although technically a floating handle, and the weather was fair, we never caught a glimpse.

Although we can’t prevent the occasional fumble by a guest, we can make finding and storing handles fast and seamless through the appropriate placement of holders near every winch. While researching this article we noticed that the vast majority of cruising boats dump the handles in rope bags and cockpit coaming pockets, and while we’ve done that when convenient, it’s not always the best solution. The handle can tangle in the rope. Coaming pockets can be an awkward reach and often become catch-alls, filled with sunscreen, reading glasses, and hats. And more importantly, there should always be a pocket within reach to minimize the temptation to rest a handle somewhere insecure.

Always keep at least one spare handle below; I’ve heard of boats that lost all of their handles during a knock-down and sailing is hard without them. Holders should be within easy reach of the winch, but where the handle can’t snag lines, won’t stab you in the back while seated, and won’t be kicked or bang knees. Vertical is normal, but a slight lean is acceptable and keeps the handle against the bulkhead. This can also be accomplished by cutting a slight scoop in the side of the holder.

LEAVE IT IN OR TAKE IT OUT?

There are good reasons to remove the handle immediately after use, some related to safety and some to efficiency. On the other hand, in moderate weather there is efficiency to be gained, or at least laziness to be served, by leaving the handle in when there may be additional trimming in the near future. This became a surprisingly polarizing discussion.

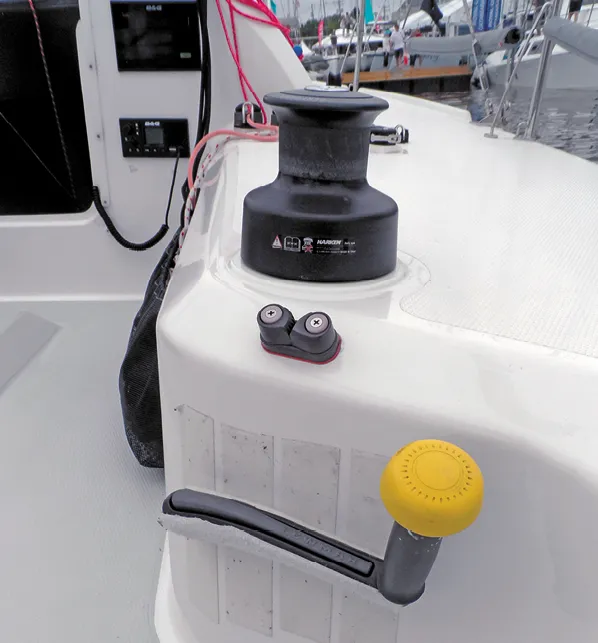

Before diving in, note that we make common reference to placing the tail in a cam cleat instead of the self-tailing jaws for many operations; we believe this is the efficient way, and if the builder did not provide cam cleats for each self-tailing winch, we advise adding them.

You can hand tail the winch in gusty weather, of course, but human nature being what it is, the tail will end up back in the jaws when it probably should not. Even racing, the trimmer may be called away for a moment to another task, which will be delayed as they wrap the line around the self-tailing jaws. The line may slip if they don’t give it a proper yank to set it. So time is wasted and now the line is not ready for immediate release. Open-top cam cleats (with no fairleads), on the other hand, always allow for a quick locking and quick release.

There is another way to quickly release a line from a self-tailing winch. After locking the line in the jaws of the self-tailer, wrap the line around the winch loosely in the reverse direction, so that a single tug will peel the line out of the jaws. This is somewhat less secure, because any tug on the line will release the sheet, but it is useful when there is no cam cleat and, for example, you are tacking a larger boat single handed. The handle should be removed, but it will work with it in place (see “Tech Tips”).

MORE WINCH RELEASE TIPS

In all cases, a line on a winch should never be released completely when under significant tension. It will run out very quickly, which can be hazardous, and serious tangles are likely, even with a well-flaked tail. Always maintain light back tension to control the release. Keep your tailing hand well away from the drum when easing.

A handle in-place makes it more difficult to add or remove turns. True, but this actually depends on the operation. When trimming in the jib during a tack it can be faster to hand-haul the bulk of the line with one turn on the drum, and then throw an additional turns over the handle, than it is to stop, insert the handle, and start cranking.

There is also the matter of removing the sheet from the self-tailer, which requires taking one wrap off the winch. When easing just a little, during active trimming, you won’t be changing the number of turns, and you will likely be grinding in more sheet within a few minutes. The tail will be in your hand or secured in a cam cleat; placing it back in the self-tailer jaws would be inefficient. When easing a sheet suddenly in a gust, the challenge may be getting the rope out of the jaws, unless you set it up for quick release.

Like reefing, as soon as it occurs to you that you might ease a sheet or tack in the near future, the tail should be removed from the jaws and placed in a cam cleat.

Jibing and tacking require throwing off most or all of the turns in a hurry. By all means, the handle should be removed from the leeward winch prior to tacking or jibing.

Some say it is “very difficult” to add turns with the handle in place. I’ve never found that to be true, or simply not harder than taking the handle out, putting is somewhere safe, and replacing it. Just take an extra second and move your arm firmly in a larger circle, well clear of the handle.

MORE REASONS FOR REMOVING WINCH HANDLES

A handle can snag lines. Common sense demands that mast winch handles come out. In the cockpit we feel this is more boat-specific. There is a possibility that other ropes will snag, most likely when the boat is severely heeled. You could be thrown against a winch, and having a handle in place will make it worse. Handles-out is a good rule in heavy weather.

You could trip on a winch handle. Do you enter and leave the cockpit by walking between or near winches? This is something to consider, although it has not been the case on boats I’ve owned.

The handle could spin and break a wrist if the pawls (there are two) fail. Pawl failure can also cause severe, often irreparable damage to the winch. However, with regular maintenance pawl failure is very, very unlikely. Replace the springs every few years and lubricate the pawls with oil, not grease.

Pawls only fail when trimming the winch, not at random. You take in a few turns, and when you let off, the handle quickly reverses, cracking the back of your hand or wrist with vicious force. I’ve had pawls stick twice, and both times I simply maintained a firm grip on the handle and either jiggled the pawls back into place, or eased the line with my other hand.

SHORT TACKING

Take the handle out immediately after trimming and prepare for the next tack—flake lines, place one turn on the windward winch, and make the handle available (but not installed, according to personal preference). The bigger the boat the more care. I take handles out most of the time, but not when trimming frequently.

Whether you prefer handles in our handles out, at some point you’ll need a handy place to stow them. Thus, the following look at options:

MOLDED PVC POCKETS

Molded PVC pockets like the Lewmar winch handle holder ($22) are inexpensive, long lasting, and do the job reasonably well. Some PVC holders lightly pinch the handle for increased security, but short of a knockdown this shouldn’t matter. A tight fit makes it slower to insert and remove the handle, and the handle can jam if pulled from an angle. We’re not big fans of tight-fitting PVC pockets.

PVC PIPE (2-INCH)

Homemade pipe holders cost about $5 and work great in corners, where conventional holders don’t fit. Take handle with you to the hardware store to check fit. Mount with two screws, and you an add 3M VHB tape for additional stability. The outer holes are drilled oversize to allow room for a screwdriver to fit.

FABRIC

Fabric holders can have seams or elastic bands that snag if the handle is pulled from an angle. They’re generally less painful to bang into, but still rigid enough you can’t comfortably lean against them. They last well, but begin to weather at about 5 years. Blue Performance sells them for $40.

LOCK-IN

There are a few compact socket holders like the Suncor Stainless Winch Handle holder ($14). We found it took us more time to return the handle to these holders. They were also more likely to cause snags and bruises from the handle sticking out.

VELCRO

Velcro-wrapped handles are common on racing boats. We didn’t expect much, and wound up surprised. Just wrap the winch handle in the soft-loop tape and slap a 3-inch x 8-inch rectangle of the matching hook tape on a handy bulkhead.

We expected the handles to come loose every time we bumped them, but the pressure only made the Velcro grip more secure. After some trial and error, we settled on mounting the handles horizontally, where they would be easier to grab.

Because the winch handle is pointing downward, there are fewer opportunities for lines to snag and nothing sticks out to bang shins. There are no holes to drill, so you can place the hook pads near every winch; you’ll have no reason to leave a handle on the deck or seat. There is no residual bump to catch a leg or jab into your back. Among racers, many feel it saves vital seconds and keeps the crew’s head up, watching the action, rather than down, fumbling for the pocket. The cost is cheap, about $5 per handle.

There are downsides to everything. The tape doesn’t stick well to all handles. For a secure bond, the side of the handle must rest flat against the bulkhead with no gaps.

Velcro will only be good for about two years in the sun (must be outdoor rated). Not all self-adhesive products can handle the heat. Look for ones that are outdoor rated.

Velcro will get dirty. Also, the hooks can grab some fabrics. But if they are mounted low this is unlikely. This was not a problem during our testing.

It must be at least 60°F to apply self-adhesive Velcro tape. Clean the surface with acetone to remove weathered gelcoat and wax, press firmly, and allow 20 minutes to build a strong bond. The bond will continue to improve for several days.

Do not use industrial rated products, such as 3M Dual Lock; they are too strong. You want the original hook and loop style with fabric hooks, not molded hooks (see “Getting a Grip on Velcro,” PS April 2016).

You can, of course, take a hybrid approach: Put a PVC pipe holder near the mast, a fixed PVC or fabric holder or two in the cockpit (as well as some rope bags or cubby holes), and Velcro patches where they are convenient.

SUMMARY

Add a holder, either a pocket or a Velcro patch, everywhere you have been tempted to sit a handle down. Like trying on shoes, take the handle with you when selecting holders. Locking vs. non-locking? We like non-locking, but it depends on your sailing style. Always keep one spare winch handle down below.

VALUE GUIDE: WINCH HANDLE HOLDERS

| MANUFACTURER | LEWMAR | BECKSON | BLUE PERFORMANCE | ROBSHIP | SUNCOR | PVC PIPE $ | VELCRO |

|---|---|---|---|---|---|---|---|

| MODEL | Winch Handle Holder | Soft-Mate Winch Handle Holder | Winch Handle Holder | Winch Handle Holder | Stainless Winch Handle Holder | DIY | DIY |

| TYPE | PVC Pocket | PVC Pocket | Fabric | Fabric | Lock-in | PVC pipe | Velcro |

| COMMENTS | Pinches to hold handle, will outlast the boat | Similar to Lewmar, pinches to hold handle, will outlast the boat | Soft when bumped into | Soft when bumped into | Hard to stow handle quickly | 2-inch inside diameter pipe | Use outdoor rated self-adhesive hook and loop |

| PRICE | $24 | $24 | $40 | $35 | $14 | $3-5 | $4-6 |

Over the years we’ve tried all kinds of bags, bins, and clips for stowing our winch handles. No one solution fits every boat. The ideal holder will keep the handle in a convenient place where it is within easy reach, yet isn’t prone to snagging lines.

1. Plastic handles are easy to modify with a hook-and-loop wrap to stay put. Handle down avoids snags.

2. The ubiquitous coaming pocket will hold a handle, but you have to reach in, and often the handle gets buried under rope and junk in these catchalls.

3. The Suncor stainless steel winch handle holder seems like an elegant solution, but it’s not as easy to use as a pocket and the handle can still snag on a line.

4. The Lewmar One-touch Winch handle secured with Velcro on a test boat. Horizontal orientation proved easier to grab and less prone to snagging, but we prefer the grip down to avoid snags.

5. A PVC pipe (right) is as practical as a fabric holder in many locations. They fit especially well in the corner of the cockpit.

6. Any winch handle that gets stowed in a deep line bin like this one is going to get rope piled on it.

7. Vinyl winch holders are relatively inexpensive, rugged and will hold the handle securely in place. A downside is their tendency to fade and attract mildew.

8. Although molded-in bins are convenient for sheets and halyards, they aren’t a good place to stow winch handles.

Non-locking handles can fall out. My one and only handle loss was at the mast. I was reefing in steep chop and I reached up to close the halyard jammer (my other hand was tailing). Away it went.

I prefer non-locking handles for sheet winches on my sporty F-24, removing them from the winch when not in use. Non-locking handles are faster in and out. The handle will be in your hand or in its pocket and a lock will only make it more likely that you’ll fumble the handle.

I prefer locking handles on my cruising cat. The sailing is a little lazier. Some racers prefer locking handles because they are less likely to come out during energetic grinding.

What about floating handles? To me, the feature itself is about as useful as a floating knife; really nice for the guy who finds it on the beach, but the odds of recovering a handle in the sort of weather that would like make you drop it are between zero and none.

I do like that floating handles are cheap, light, kind on gelcoat, and because they work great with Velcro. They are a little flexible and I have broken one. They can also be a tight fit in some holders.

What length? A 10-inch winch handle gives more power if the winches are marginal in size or you are feeling weak. An 8-inch handle spins faster and is easier to reach around when adding or removing turns. The choice is yours.

I have several types on the boat. I keep locking, non-floating 10-inch winch handles at the mast. Floating 8-inch handles are good for the chute, and non-locking 10-inch handles manage the genoa.

The single-hander is wise to use every available shortcut to simplify sail-handling. By preparing the loaded genoa sheet prior to tacking you can release the sheet with a series of wrist-flicks—one flick to release from the self tailer, two or three more to remove remaining wraps.

1. With the sheet still tightly clamped in the self-tailing jaws, the sheet is led back around the winch.

2. A sharp tug peels the sheet out of the jaws of the self-tailer.

3. With practice you can throw off subsequent wraps without leaving the helm.