Extremely low friction allows Amsteel and other high molecular weight polyethylene (HMPE) lines to run like lightening through low friction rings. Unfortunately, they also run right through cleats, jammers, and your hands. If a jammer did hold-and it wont-the load would probably exceed the capacity of any device that matched the lines tiny size.

The description that follows assumes you have access to the tail of an HMPE rope, such as a halyard, that youd like to cover, but that the other end is already installed. When determining where the splice for the new cover should end, remember to move the rope through its full range of motion. This description also assumes you’ve attained a relatively competent marlinspike skills. As illustrated in the accompanying article “Working with High Tech Ropes,”lack of attention to detail here can have serious, even fatal, consequences.

Choose a cover. Polyester is standard, it is inexpensive and durable with good friction characteristics. To fit properly, the cover diameter must be about 2 mm larger than the HMPE halyard. An easy way to know if the donor rope has the right size cover is to see if its core is the same diameter size as the HMPE line you want to cover. A few suppliers sell cover-only products. This will have a messenger core inside, used only to pull the new core into the cover. It is often just as cheap to look for a good price on polyester double-braid. The cover of an old halyard, taken from the middle section that was protected from the elements inside the mast will work.

Mark the Dyneema Core

This mark should be about 2 feet before the jammer when the sail is raised. This allows enough length for burying the cover, making halyard adjustments, and to account for normal stretch in the line. Tape the ends of the donor line, but do not melt them. Melted ends are snag-prone when splicing.

Mark the cover on the donor rope

This mark should be about six inches from the end that you will be splicing to the HMPE rope.

CLICK IMAGE TO ENLARGE

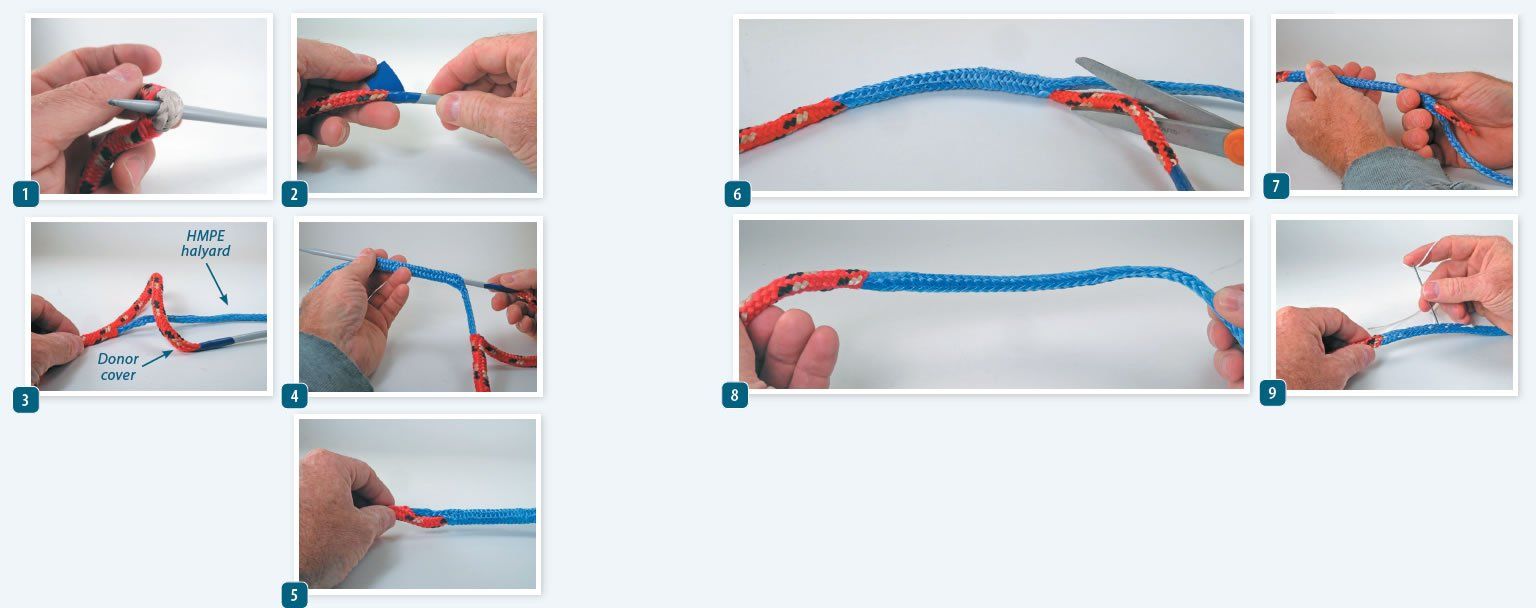

1. Using a fid, poke through the cover at the mark on the cover and extract the end of the donor line core (messenger core). You now have a Y at the end of your donor line-one arm is the donor ropes core (to be used as a messenger), the other arm is the cover that will be spliced to the HMPE core and secured.

1a. (Not pictured.) Join the donor core messenger to the end of the HMPE halyard. Use a butt splice-whip each line, link the whippings with thread, and finally cover with tape. From the free end of the donor rope, pull on the donor core. Pull just enough to be able to slide the donor cover over HMPE halyard and up to the mark you made on it. The donor cover will now be in position, with 6 inches of loose cover flopping off to one side.

2. Tape the end of the loose piece of cover to a fid, it doesn’t have to be tight.

3. Now, the new Dyneema core has buried into the donor core, up to the initial mark you made on the core.

4. Insert the fid into the HMPE halyard and pull the cover into the center of the Dyneema halyard, then exit the halyard about one fid-length distant.

5. As the splice is snugged, the crossover point should appear like this.

6. Milk the cover towards the crossover until it is tight. Bunch up the Dyneema halyard to expose more of the cover, and trim the tail of the cover on an angle so that it is tapered

7. Milk the halyard back over the tapered cover.

8. Finally, the tapered cover disappears into the Dyneema halyard.

9. Finish by lock-stitching the splice with whipping twine for about 4 inches. Make the stitches parallel to the cover strands, so that they lie below the cover, minimizing chafe. The stitching does not carry the load. Tension the stitching just enough to pull the splice snug while you are stitching.

Tension the cover firmly by pulling hard on it against the splice and milking it down all the way the new rope you’ve made. You do not want the cover loose or it will bunch up and slip in the jammer or cleat. If the cover extends clear to the tail of the HMPE core, trim them to match length and whip firmly together.